-

Evolution of Automatic Cement Block Making Machine. Working Principle of Automatic Cement Block Making Machine. Raw Material Preparation. Block Formation. Curin...

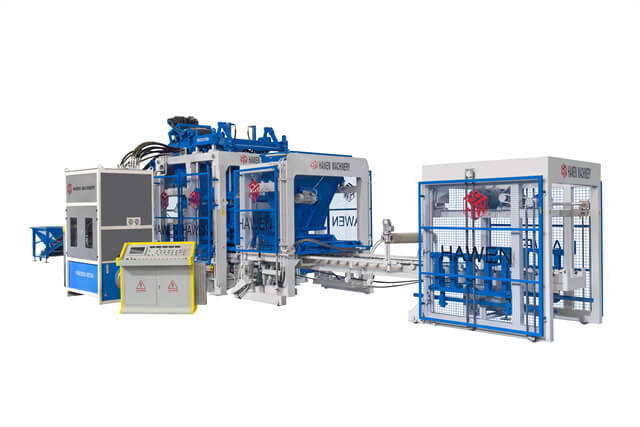

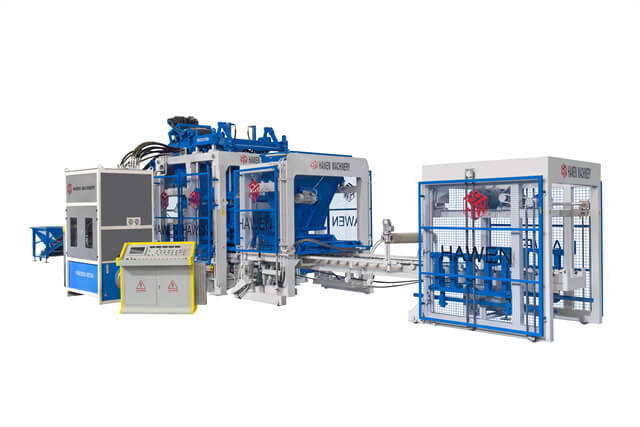

Cement Block Making Machine

-

.jpg)

Introduction. 1. Early Designs. 2. Advancement in Mould Design. 3. Mechanical Assistance. 4. Introduction of Vibrating Technology. 5. Automation and Electric Mo...

Cement Block Making Machine

-

1. Introduction. 2. Early Development. 3. Advancements in Technology. 4. Modern Features. 5. Working Principles. 6. Applications. 7. Safety Considerations. 8. F...

Concrete Block Cutting Machine

-

Introduction. Early Development. Technological Advancements. Modern Innovations. Working Principles. Advantages and Applications. Conclusion....

Automatic Hollow Block Machine

-

Early Methods of AAC Block Production. Introduction of Automated Machinery. Incorporation of Advanced Materials. Evolution of Modern Manufacturing Machines. Wor...

AAC Block Manufacturing Machine

-

Introduction. 1. History of Concrete Blocks. 2. Composition of Concrete Blocks. 3. Manufacturing Process. 4. Different Types of Concrete Blocks. 5. Quality Cont...

Concrete Block Manufacturing

-

1. Equipment and Tools. 2. Site Preparation. 3. Machine Assembly. 4. Mixing the Concrete. 5. Block Production. 6. Curing. 7. Maintenance and Troubleshooting. 8....

Hollow Block Machine

-

The construction industry demands precision, efficiency, and durability in equipment, especially when producing essential building materials like blocks, bricks...

Blockmakingmachine

-

Choosing a concrete block/brick /paver making machinefrom China can be a smart mov e. China is a leading manufacturer of concrete block making machine , and th...

-

A Concrete Blocks, Bricks, and Pavers Independent Cuber System is an automated or semi-automated machine designed to efficiently stack, organize, and prepare co...

Concrete blocks Independent Cuber System

-

.jpg)

Plant Size and Production Capacity. Types of Brick Production Methods. Technological Advancements. Operational and Maintenance Needs. Health and Safety Consider...

brick making plant

-

Initial Purchase Cost. Operational Costs. Maintenance Costs. Repair Costs. Labor Costs. Insurance Costs. Training and Skill Development Costs. Conclusion....

interlocking brick making machine

-

Types of Brick-Making Machines. Capacity and Production Output. Features and Specifications. Brand and Manufacturer. Geographical Location and Shipping Costs. C...

brick making machine

-

Types of Paver Block Machines. Factors Influencing Cost. Cost Range for Different Types. Additional Costs to Consider. Where to Buy and How to Save. Conclusion....

paver block machine

-

Understanding Brick Machine Production Lines. Types of Brick Machines and Their Electricity Consumption. Factors Influencing Electricity Consumption. Calculatin...

brick machine production line

.jpg)

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China