How Automatic Block Machines Differ from Manual Systems

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-01-13

How Automatic Block Machines Differ from Manual Systems

In the concrete block manufacturing industry, the choice between automatic block machines and manual systems has a direct impact on productivity, quality, labor costs, and long-term profitability. While manual machines remain suitable for small-scale operations, automatic systems have become the standard for professional and industrial production. The key differences are outlined below.

1. Level of Automation and Control

Manual block machines rely heavily on human operation for material feeding, vibration, mould handling, and brick removal. As a result, production consistency depends largely on operator skill and experience.

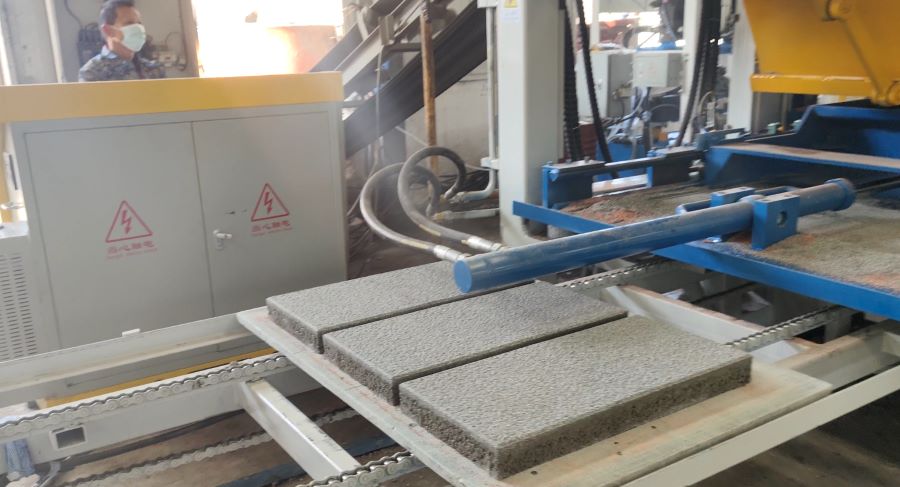

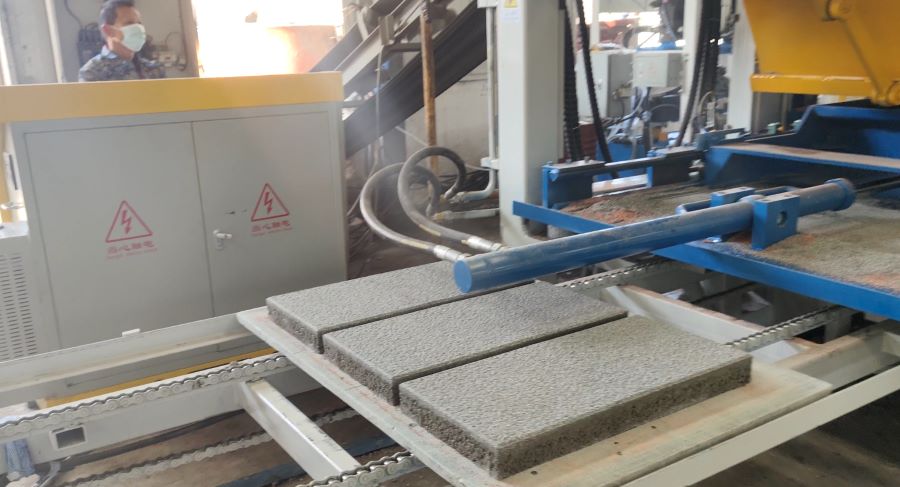

Automatic block machines, by contrast, integrate PLC-controlled systems, hydraulic drives, and synchronized vibration units. Material distribution, forming, demoulding, and pallet handling are fully automated, ensuring precise control and repeatable results with minimal human intervention.

2. Production Capacity and Efficiency

Manual systems typically produce blocks in small batches with longer cycle times. Output is limited, making them suitable mainly for low-demand or start-up projects.

Automatic machines are designed for continuous, high-output production. With optimized cycle times and automated material flow, they can produce thousands of blocks per day, significantly improving efficiency and meeting large-scale market demand.

3. Product Quality and Consistency

In manual production, variations in vibration, pressure, and timing often lead to inconsistent block density, strength, and appearance.

Automatic block machines apply uniform vibration and hydraulic pressure, resulting in blocks with higher compressive strength, accurate dimensions, and consistent surface finish. This consistency is critical for meeting international standards and competing in professional construction markets.

2. Production Capacity and Efficiency

Manual systems typically produce blocks in small batches with longer cycle times. Output is limited, making them suitable mainly for low-demand or start-up projects.

Automatic machines are designed for continuous, high-output production. With optimized cycle times and automated material flow, they can produce thousands of blocks per day, significantly improving efficiency and meeting large-scale market demand.

3. Product Quality and Consistency

In manual production, variations in vibration, pressure, and timing often lead to inconsistent block density, strength, and appearance.

Automatic block machines apply uniform vibration and hydraulic pressure, resulting in blocks with higher compressive strength, accurate dimensions, and consistent surface finish. This consistency is critical for meeting international standards and competing in professional construction markets.

4. Labor Requirements and Operating Costs

Manual systems require more operators for feeding, forming, handling, and stacking blocks, increasing labor dependency and long-term operating costs.

Automatic systems significantly reduce labor needs. One production line can be operated by a small, well-trained team, lowering workforce costs while improving workplace safety and efficiency.

5. Flexibility and Product Range

Manual machines usually support limited mould options and product types, restricting diversification.

Automatic block machines support quick mould changes and can produce a wide range of products, including hollow blocks, solid blocks, paving stones, kerbstones, and specialty blocks. This flexibility allows manufacturers to respond quickly to market demand.

4. Labor Requirements and Operating Costs

Manual systems require more operators for feeding, forming, handling, and stacking blocks, increasing labor dependency and long-term operating costs.

Automatic systems significantly reduce labor needs. One production line can be operated by a small, well-trained team, lowering workforce costs while improving workplace safety and efficiency.

5. Flexibility and Product Range

Manual machines usually support limited mould options and product types, restricting diversification.

Automatic block machines support quick mould changes and can produce a wide range of products, including hollow blocks, solid blocks, paving stones, kerbstones, and specialty blocks. This flexibility allows manufacturers to respond quickly to market demand.

6. Long-Term Investment Value

Although manual machines require lower initial investment, their limited capacity, higher labor costs, and inconsistent quality often restrict business growth.

Automatic block machines represent a strategic long-term investment. Higher upfront costs are offset by superior productivity, stable quality, reduced labor expenses, and stronger market competitiveness.

Conclusion

Manual block machines serve basic production needs, but automatic block machines are purpose-built for scalable, efficient, and professional manufacturing. For businesses aiming to expand capacity, improve quality, and secure long-term returns, automation is not merely an upgrade—it is a decisive advantage.

6. Long-Term Investment Value

Although manual machines require lower initial investment, their limited capacity, higher labor costs, and inconsistent quality often restrict business growth.

Automatic block machines represent a strategic long-term investment. Higher upfront costs are offset by superior productivity, stable quality, reduced labor expenses, and stronger market competitiveness.

Conclusion

Manual block machines serve basic production needs, but automatic block machines are purpose-built for scalable, efficient, and professional manufacturing. For businesses aiming to expand capacity, improve quality, and secure long-term returns, automation is not merely an upgrade—it is a decisive advantage.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China