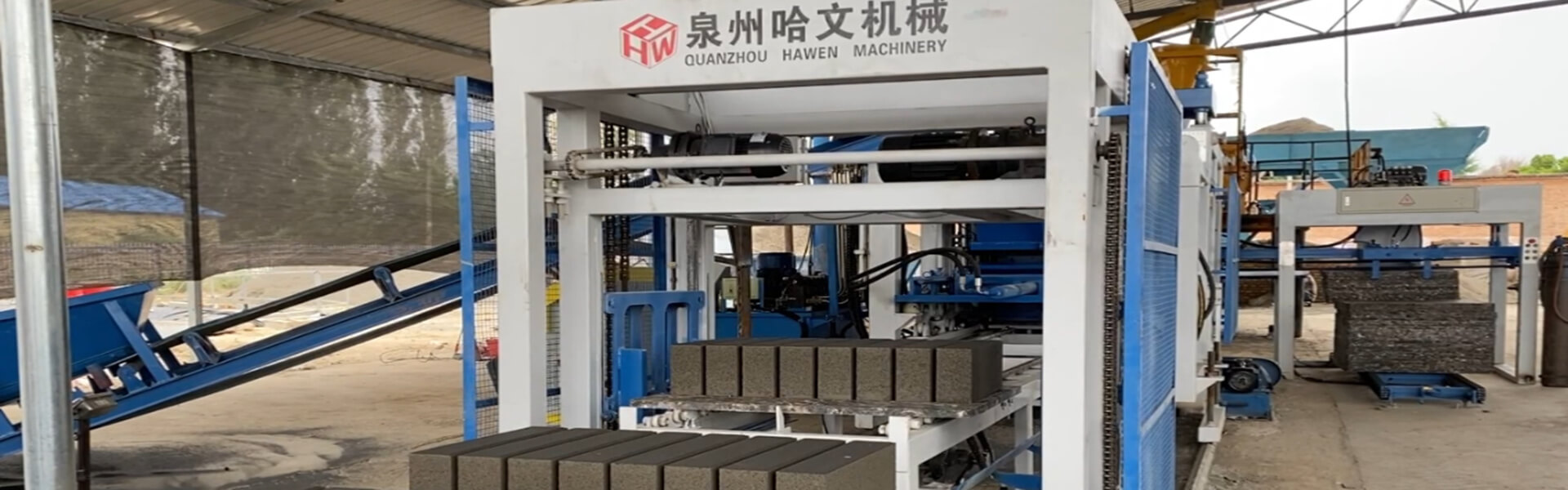

The Automatic Concrete Block Production Line and Paver-Making Machine is a sophisticated and efficient solution designed for the automated production of high-quality concrete blocks and pavers, it is the medium size of concrete block making machine,with the pallet size at 980x680mm.

This innovative system is equipped with advanced technology to streamline the manufacturing process and enhance productivity while maintaining exceptional product quality.

Technical Features

The production line incorporates state-of-the-art components such as automatic batching systems, precise mixing equipment, and high-capacity block molding machines.It also integrates advanced control systems for monitoring and regulating the production process, ensuring consistent quality and uniformity in the finished products.

The machine is designed for versatility, allowing the production of various types and sizes of concrete blocks and paver to meet diverse construction needs.

Brick making flow chart introduction

|

NO.

|

Name of Machine

|

Note

|

|

1

|

Batching machine

|

Qty. Of strorage bin can be customized

|

|

2

|

Skip hoist for Concrete mixer

|

Another option: Conveyor belt

|

|

3

|

Cement scale

|

|

|

4

|

Screw conveyor

|

|

|

5

|

Cement Silo

|

Can be prepared by customer locally

|

|

6

|

Conveyor belt for aggregate material

|

|

|

7

|

Block making machine

|

|

|

8

|

Face material conveyor belt

|

|

|

9

|

Face material mixer

|

|

|

10

|

Automatic block stacker

|

|

|

11

|

Hydraulic station

|

|

|

12

|

Control system for batching and mixing

|

Optional

|

|

13

|

Control system for block machine

|

|

|

Note: It requires 1500-2000pcs of production pallet for production

|

The main functions of the Automatic Concrete Block Production Line and Paver-Making Machine include automated raw material feeding,precise mixing of concrete ingredients, accurate molding and compacting of blocks and pavers, and efficient curing and stacking of the finished products. The system is capable of high-speed production with minimal manual intervention, resulting in increased output and reduced labor costs.

Additionally, it ensures consistent product quality and dimensional accuracy, meeting the stringent standards of the construction industry. In conclusion, the Automatic Concrete Block Production Line and Paver-Making Machine represents a cutting-edge solution for modern construction needs, delivering superior performance, efficiency, and versatility in the production of concrete blocks and paver.

Its advanced features, broad applicability, and reliable operation make it an indispensable asset for businesses seeking to optimize their manufacturing processes and meet the demands of the construction market.

This production line and paver-making machine is ideal for use in the construction industry, offering a reliable and cost-effective solution for producing concrete blocks and pavers.

It can be employed in the manufacturing of interlocking pavers, standard concrete blocks, and specialized products for a wide range of applications including roads, pavements, landscaping, and building construction.

|

Capacity Sheet for QT6-15 Automatic block making plant

|

|

No.

|

Name

|

Dimension (mm)

( LxWxH)

|

Number of block per Pallet

|

Block /1hour

Estimated

|

Block /8hours

Estimated

|

|

1

|

Hollow block

|

400x200x200mm

(8 inch )

|

6

|

1,080

|

8,640

|

|

2

|

Hollow block

|

400x150x200mm

(6 inch )

|

8

|

1,400

|

11,500

|

|

3

|

Hollow block

|

400x100x200mm

(4 inch )

|

10

|

1,800

|

14,400

|

|

4

|

Square shape paver

|

250x250x60mm

|

6

|

1,080

|

8,640

|

|

5

|

Interlocking paver

|

200x100x60mm

|

24

|

4,300

|

34,400

|

|

6

|

Rectangle Paver

|

200x100x60mm

|

24

|

4,300

|

34,400

|

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

We are extremely satisfied with the Pavers Making Machine QT6-15. It's robust, produces blocks of uniform quality, and its energy-efficient design has helped us reduce our carbon footprint.Benjamin R. 2024-07-20

QT6 automatic concrete block production line and paver-making machine is a top-notch product that has exceeded our expectations. It's easy to set up, produces blocks with excellent dimensional accuracy, and its energy-efficient operation has helped us reduce costs.Jordi Pinilla 2024-06-12

The QT6-15 has been instrumental in our success as a construction company. It's a time-saving investment that has allowed us to complete projects faster without compromising on quality.Victoria L. 2024-07-20

The QT6-15Solid brick making machine has transformed our construction site. It's fast, reliable, and produces blocks with precise dimensions, ensuring a seamless fit in our structures.Laura Bright 2024-07-20