QT6 Automatic Block Making Plant Successfully Shipped to Client in Uzbekistan

On the third week of October, a QT6-15 Automatic Block Making Plant manufactured by HAWEN MACHINERY was successfully shipped from our factory, and is expected to arrive in Tashkent, Uzbekistan in mid-November.

This order marks another successful step for HAWEN MACHINERY in the Central Asian market.

The cooperation began after the client personally visited our factory, carefully examined the production process, and compared technical parameters, quality, and service among multiple manufacturers. After a thorough evaluation, the client finally chose HAWEN MACHINERY as their trusted supplier for a complete concrete block production solution.

*Advantages of QT6-15 Block Making Plant

1. Durable QT6-15 Block Making Machine

Built with high-strength steel and precision welding, ensuring stability and long service life under continuous operation. The PLC control cabinet adopts SIEMENS components, providing intelligent, reliable, and easy-to-use control with automatic fault diagnosis and remote support.

Delivers high pressure and stable forming for consistent block strength and precision. The hydraulic pallet provider ensures smooth pallet movement and stable pressure during block forming.

QT6-15 block making machine

PLC Control cabinet

2. Efficient Mixing System

The line includes a JS500 concrete mixer for accurate and uniform material mixing, ensuring excellent block quality and consistency. A water spray device automatically adjusts the water-cement ratio for optimal mixing performance.

JS500 concrete mixer

3. Automatic Stacker System

Enables automatic stacking of finished blocks, improving efficiency and reducing labor costs. Combined with the wet block conveyor, it provides smooth block transfer and stable stacking operation.

Block stacker

4. High Production Efficiency

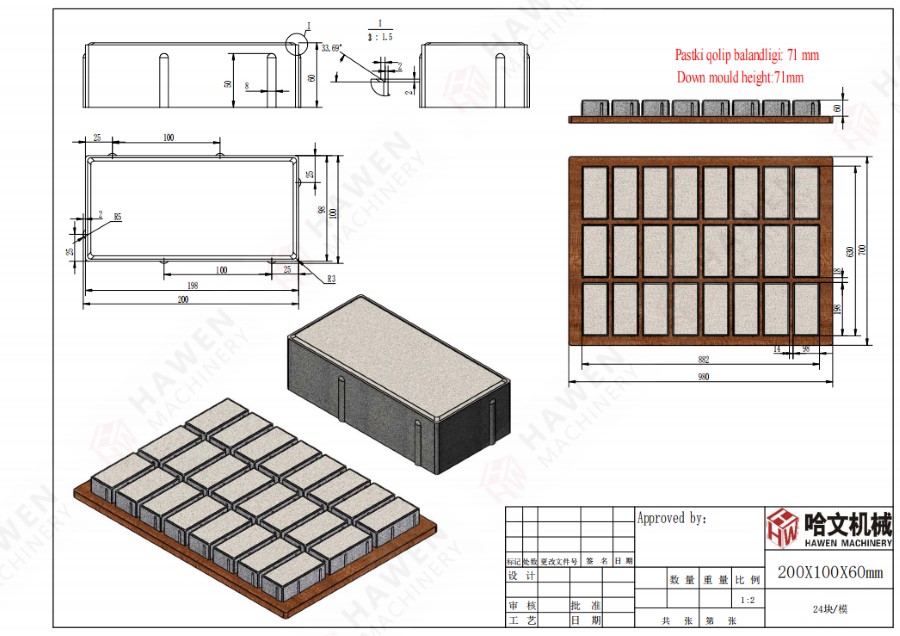

Can produce up to 35,000 pieces of 200x100x60mm rectangle paver per 8-hour shift; 9,000 pieces of 400x200x200mm hollow blocks per 8-hour shift, depending on the materials used. Equipped with a pallet feeder and wet block conveyor, the system ensures continuous feeding and efficient material flow throughout the production process.

5.Enhanced Surface Finish with Water Spray Device

A water spray device is also included in the QT6-15 Block Making Plant, which can produce an exceptional stone surface effect, adding a smooth and polished finish to the surface of pavers. This feature is especially beneficial for producing high-quality paving stones, enhancing their visual appeal and durability, making them ideal for premium construction projects.

Water spray device

6.Flexible Mould Options

Capable of producing a wide range of products — paving stones, kerbstones, hollow blocks, and solid bricks — with simple mould changes. Optional facemix device and facemix mixer allow for the production of colored and double-layer paving stones, meeting diverse market demands.

7.Energy Saving & Low Maintenance

Optimized vibration and hydraulic design ensure energy efficiency, smooth operation, and reduced maintenance costs. High-quality components from SIEMENS and YUKEN guarantee durability and easy serviceability.

8.Customer’s Confidence and Satisfaction

The client expressed full satisfaction with HAWEN MACHINERY’s professional communication, transparent pricing, and technical expertise. They highlighted that HAWEN Machinery’s machine structure, PLC control system, and block quality exceeded expectations compared with other suppliers they visited.

This successful cooperation lays a solid foundation for future partnership in Uzbekistan and the broader Central Asian region.

*Hot Testing Before Shipment

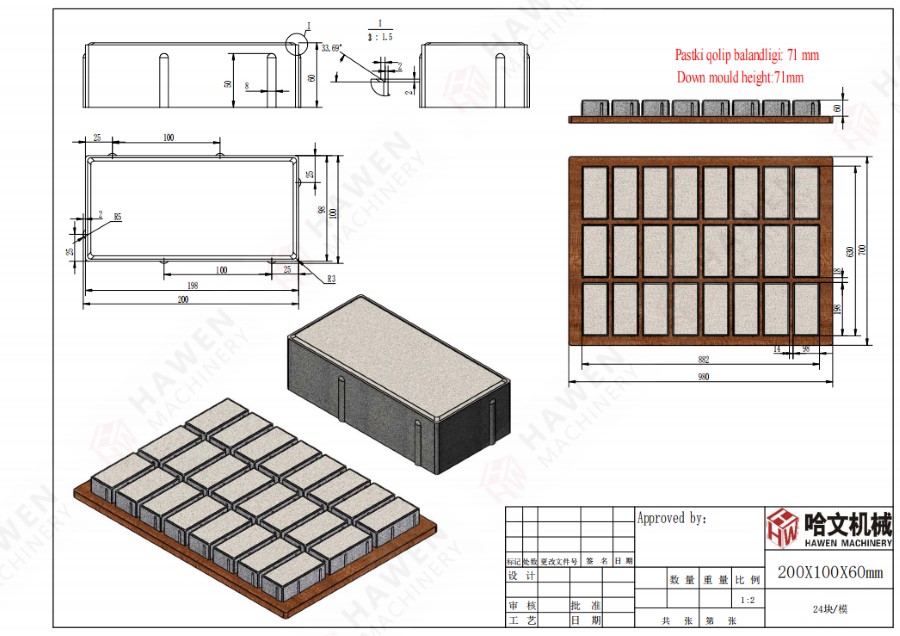

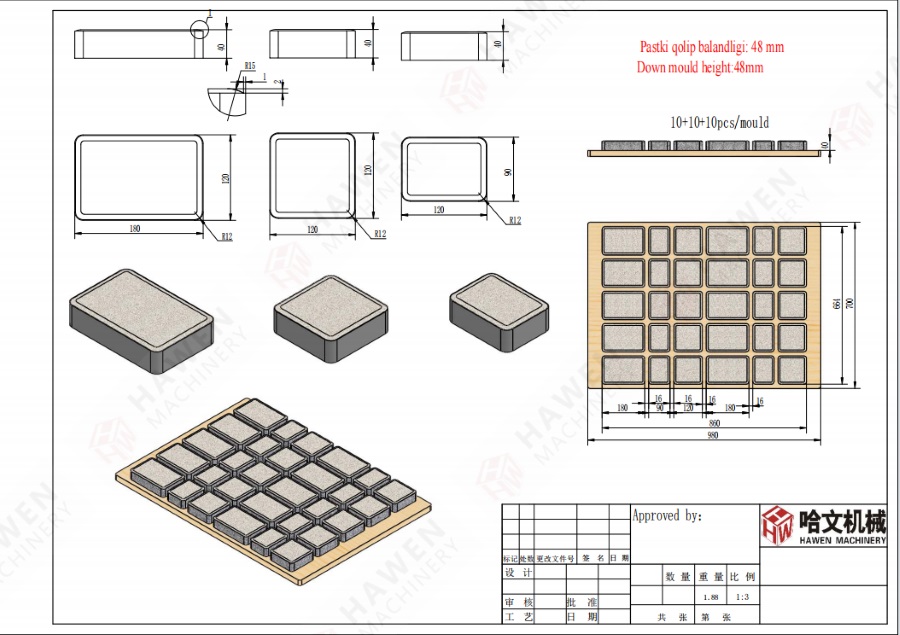

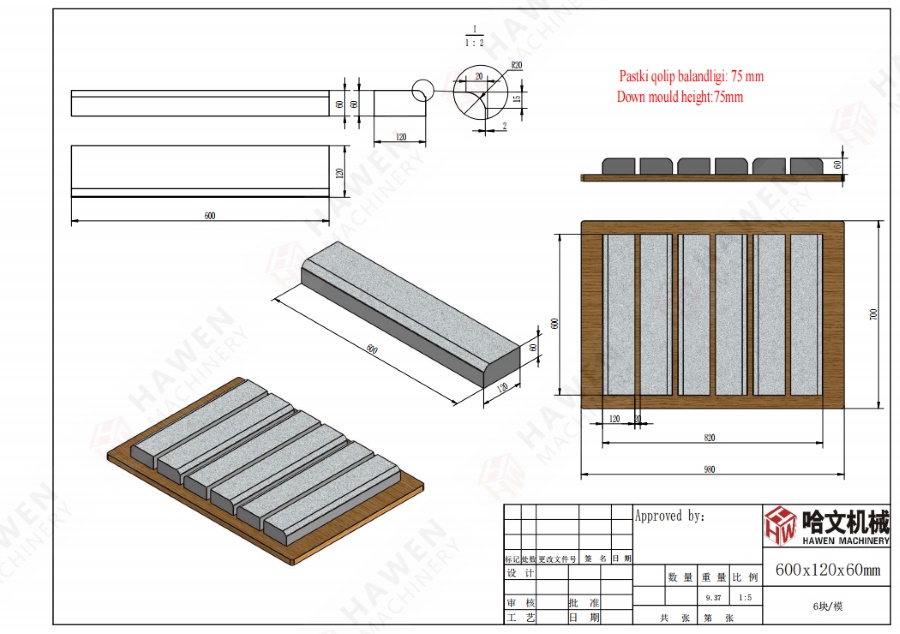

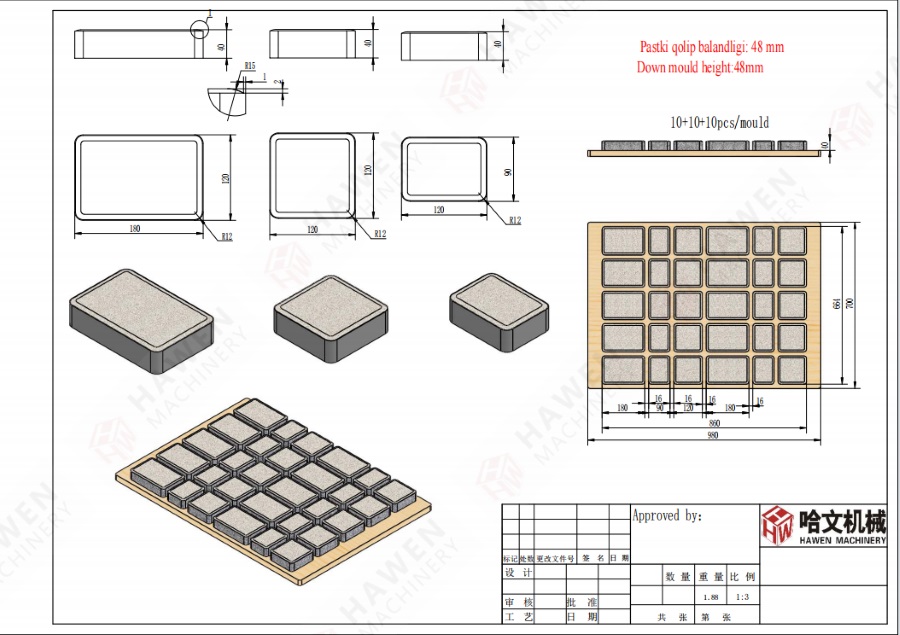

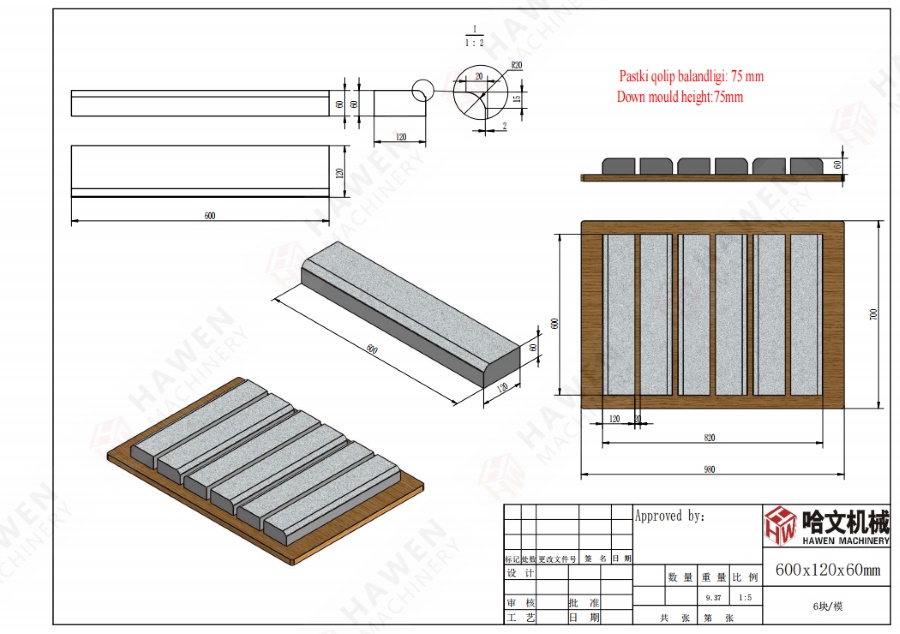

Before shipment, the QT6-15 Block Making Plant underwent strict factory hot testing to ensure optimal performance and quality. During this hot testing, the QT6-15 Block making machine produced pavers using molds customized according to the client’s specifications, allowing us to verify that the equipment could consistently produce the exact rectangle pavers and curbstones required. This thorough testing process guaranteed that the block making plant met the client’s standards and ensured a smooth start-up at their site.

Below is photo of pavers produced during factory testing using the molds customized according to the client’s specifications.

Hot testing photo

*Why the Client Chose HAWEN MACHINERY

During their visit, the customer observed HAWEN Machinery’s modern production facilities, strict quality control system, and professional team.They were particularly impressed by the robust design and finishing quality of the QT6-15 machine and the transparency of our technical demonstration.

1.Meeting Client’s Production Needs

The client specializes in producing rectangle pavers and curbstones, which are widely used in road construction, landscaping, and urban infrastructure projects. The QT6-15 Block Making Plant, with its flexible mould options and high production capacity, is the perfect fit for producing these high-demand products. With the ability to change moulds easily, the plant can meet various production requirements, providing excellent quality and consistency for both pavers and curbstones.

Below are the photos about the mould drawing of rectangle pavers and curbstones.

Rectangle paver

Rectangle pavers

Curb stone

2.Reliable Performance and Flexibility

The QT6-15 block making machine features a hydraulic forming system, vibration platform, and intelligent PLC control, ensuring stable operation and high precision.

By changing moulds, the machine can produce hollow blocks, solid bricks, paving stones, and curbstones, offering great flexibility for local market demand.

3.Efficient and Energy-Saving Design

The optimized vibration system delivers strong compaction with low energy consumption, resulting in dense, durable blocks while minimizing mechanical wear.

4.Intelligent Control and Easy Operation

Equipped with SIEMENS PLC intelligent control, the machine offers automatic fault diagnosis, touch-screen operation, and easy parameter adjustment, making it user-friendly and reliable.

5.Professional Service and Long-Term Support

From pre-sale consultation to shipment and future installation, HAWEN Machinery’s team provides comprehensive technical support.

Our experienced engineers will assist the customer with on-site installation, commissioning, and training, ensuring the plant runs smoothly and efficiently from day one.

Loading picture

*Conclusion

The successful shipment of the QT6-15 Block Making Plant to Tashkent, Uzbekistan once again proves HAWEN MACHINERY’s strong capability in delivering high-quality, intelligent, and reliable block production solutions.

From precision manufacturing and strict testing to on-time delivery and professional service, HAWEN remains committed to helping clients worldwide build sustainable and efficient block factories.

HAWEN MACHINERY — Your Trusted Partner for Concrete Block Production Solutions.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China