-

1. Introduction. 2. Evolution of Hand Block Moulding Machines. 3. Components of Hand Block Moulding Machines. 4. Working Principles of Hand Block Moulding Machines. 5. Advantages of Hand Block Mouldin...

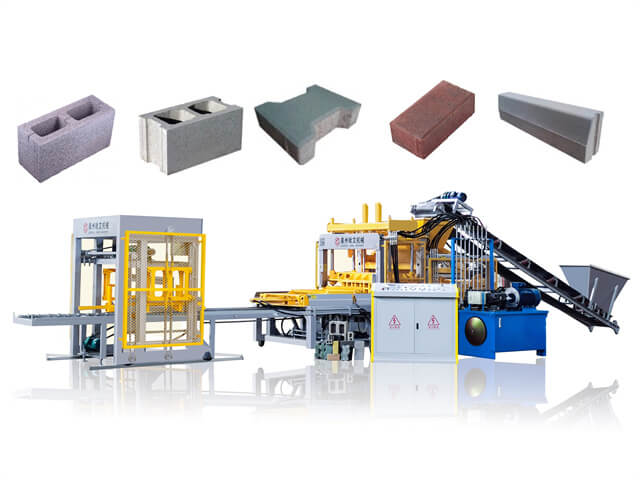

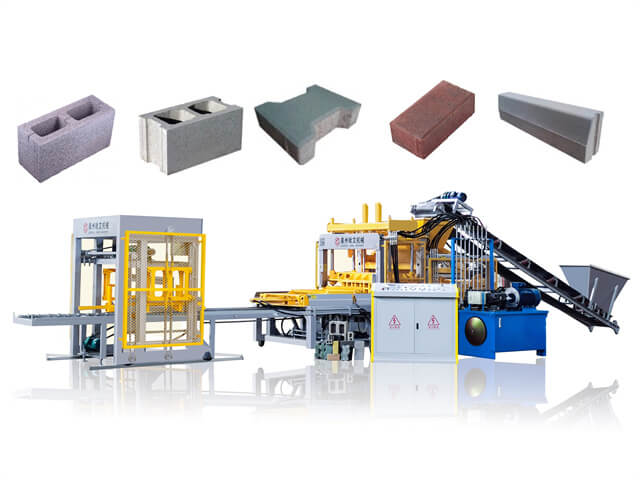

Block Moulding Machine

-

Planning and Design. Excavation and Preparation. Formwork and Reinforcement. Concrete Mixing and Pouring. Curing and Finishing. Installation of the Block Moulding Machine. Conclusion....

block moulding machine

-

Understanding the Importance of Accurate Mixtures. Key Components of a Block Mixture. Choosing the Right Proportions. Using Automated Mixers. Regular Calibration and Maintenance. Testing and Quality C...

block moulding machine

-

Types of Block Moulding Machines. Space for Raw Materials. Space for Finished Products. Operational Space. Additional Considerations. Conclusion....

block moulding machine

-

Stage 1: Design and Development. Stage 2: Raw Material Selection and Procurement. Stage 3: Machining. Stage 4: Assembly. Stage 5: Testing and Quality Control. Stage 6: Packaging and Shipping. Stage 7:...

Hollow Block Moulding Machine

-

Introduction. 1. Design and Engineering. 2. Material Selection and Procurement. 3. Fabrication of Components. 4. Assembly and Integration. 5. Quality Control and Testing. 6. Finishing and Painting. 7....

-

Step 1: Preparing the Site. Step 2: Assembling the Machine. Step 3: Testing and Calibration. Step 4: Routine Maintenance. Step 5: Cleaning. Step 6: Replacement of Worn Out Parts. Step 7: Upgrades and ...

EPS Block Moulding Machine

-

1. Equipment Setup. 2. Electrical and Hydraulic Connections. 3. Startup and Testing. 4. Regular Maintenance. 5. Troubleshooting. 6. Safety Precautions. 7. Cleaning and Storage. 8. Training and Documen...

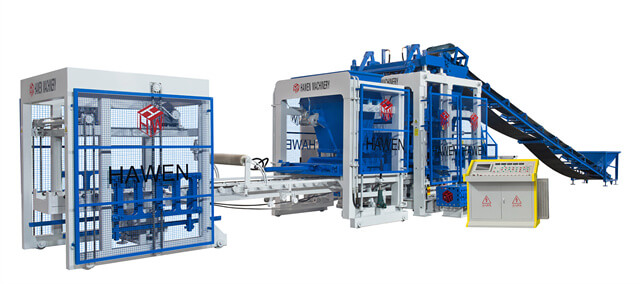

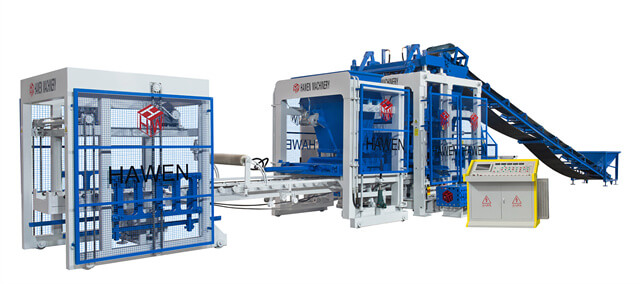

Hollow Block Moulding Machine

-

1. Pre-installation Preparation. 2. Machine Assembly. 3. Electrical Connections. 4. Lubrication. 5. Inspection and Cleaning. 6. Regular Maintenance. 7. Safety Measures. 8. Troubleshooting. Conclusion....

Cement Block Moulding Machine

-

1. Raw Material Preparation. 2. Pre-Expanding. 3. Mould Preparation. 4. Heating and Conditioning. 5. Mould Filling. 6. Cooling and Demoulding. 7. Trimming and Shaping. 8. Final Inspection and Packagin...

Block Machine

-

1. Increased Efficiency. 2. Versatility in Block Sizes and Shapes. 3. Consistent Block Quality. 4. Cost-effective Solution. 5. User-friendly Operation. 6. Durability and Longevity. 7. Customizable Fea...

Block Moulding Machine

-

Selecting the Right Machine . Preparing the Work Area. Preparing the Concrete Mix. Loading the Machine. Moulding Process. Curing the Blocks. Cleaning the Machine. Maintenance. Conclusion. ...

brick making machine

-

Market Overview. Market Segmentation. Factors Driving Market Growth. Challenges Facing the Market. Key Players in the Market. Market Trends. Future Outlook. Conclusion....

Block Moulding Machine

-

.jpg)

Introduction. 1. Understanding the Machine. 2. Preparing the Material. 3. Setting Up the Machine. 4. Operating the Machine. 5. Safety Considerations. 6. Maintenance and Troubleshooting. 7. Improving E...

Block Moulding Machine

-

1. Frame and Support Structure. 2. Moulding Chamber. 3. Hydraulic System. 4. Mixing and Feeding Mechanism. 5. Control and Automation Systems. 6. Block Ejection and Handling. 7. Safety Features and Gua...

Block Moulding Machine

.jpg)

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China