QT6-15 Paver and Curb Stone Making Plant Successfully Running in Uzbekistan

The QT6-15 paver and curb stone making plant supplied by HAWEN MACHINERY has been successfully installed and put into operation in Qarshi City, Uzbekistan. Following smooth installation, commissioning, and stable trial production, the plant is now running reliably, delivering high-quality pavers and curbstones for local infrastructure and landscaping projects.

This successful start-up marks another milestone for HAWEN MACHINERY in the Central Asian market, demonstrating our ability to provide complete, efficient, and intelligent block production solutions that perform under diverse environmental conditions.

Client Background and Project Motivation

The client is a leading supplier of rectangular pavers and curbstones serving urban infrastructure, road construction, and landscaping projects in Qarshi City. With increasing market demand, the client faced limitations with their previous production setup, including restricted output capacity, inconsistent product quality, and high labor dependence.

To enhance production efficiency, ensure stable product quality, and support long-term business growth, the client decided to invest in a modern, fully automated paver and curb stone making plant. After evaluating multiple suppliers and conducting detailed technical comparisons, HAWEN MACHINERY was selected as the trusted partner for this strategic investment.

Client Background and Project Motivation

The client is a leading supplier of rectangular pavers and curbstones serving urban infrastructure, road construction, and landscaping projects in Qarshi City. With increasing market demand, the client faced limitations with their previous production setup, including restricted output capacity, inconsistent product quality, and high labor dependence.

To enhance production efficiency, ensure stable product quality, and support long-term business growth, the client decided to invest in a modern, fully automated paver and curb stone making plant. After evaluating multiple suppliers and conducting detailed technical comparisons, HAWEN MACHINERY was selected as the trusted partner for this strategic investment.

Installation, Commissioning, and Successful Start-Up

Upon arrival of the equipment at the customer's factory, HAWEN MACHINERY promptly dispatched experienced technicians to Qarshi City to provide on-site guidance for installation and commissioning.

With close cooperation between our technical team and the client's operators, the installation and system integration were completed within approximately one week. Following systematic testing, parameter optimization, and trial operation, the QT6-15 paver and curb stone making plant was successfully put into production.

Given that Qarshi City experiences winter temperatures dropping to 0°C or below, the QT6-15's hydraulic system is equipped with a heating function to ensure that hydraulic oil maintains optimal viscosity, allowing smooth and uninterrupted production even under cold conditions.

From the initial start-up, the plant demonstrated smooth, stable, and continuous operation, fully meeting the client’s requirements for productivity, quality, and operational reliability.

Plant Highlights and Technical Advantages

1. Robust and Efficient QT6-15 Block Making Machine

Heavy-duty frame manufactured from high-strength steel with precision welding ensures long-term stability under continuous operation.

Equipped with Japanese YUKEN hydraulic forming system and advanced vibration platform for high-density, high-strength products.

Hydraulic oil heating system ensures reliable operation during low-temperature winter conditions.

Siemens PLC control system enables intelligent operation, automatic fault diagnosis, and reliable process control.

2. Accurate and High-Performance Mixing System

JS500 forced concrete mixer ensures uniform material blending and accurate mix ratios.

Integrated water spray device automatically regulates the water–cement ratio, improving product consistency and surface finish.

3. Automated Stacking and Conveying System

Automatic block stacker and wet block conveyor ensure smooth product transfer and efficient stacking. Significantly reduces labor requirements while maintaining continuous production flow.

4. Automatic Pallet Provider

The automatic pallet provider ensures continuous and stable pallet feeding to the block making machine throughout the production process. By automatically supplying pallets at the correct timing and position, it eliminates manual pallet handling and prevents production interruptions caused by pallet shortages or misalignment.

This system significantly improves production continuity and operational efficiency, while reducing labor intensity and ensuring consistent forming quality.

5. Flexible Mould Options and High Production Capacity

The QT6-15 paver and curb stone making plant provides exceptional mould flexibility, supporting a wide range of pavers and curbstones:

Standard rectangular pavers:

Installation, Commissioning, and Successful Start-Up

Upon arrival of the equipment at the customer's factory, HAWEN MACHINERY promptly dispatched experienced technicians to Qarshi City to provide on-site guidance for installation and commissioning.

With close cooperation between our technical team and the client's operators, the installation and system integration were completed within approximately one week. Following systematic testing, parameter optimization, and trial operation, the QT6-15 paver and curb stone making plant was successfully put into production.

Given that Qarshi City experiences winter temperatures dropping to 0°C or below, the QT6-15's hydraulic system is equipped with a heating function to ensure that hydraulic oil maintains optimal viscosity, allowing smooth and uninterrupted production even under cold conditions.

From the initial start-up, the plant demonstrated smooth, stable, and continuous operation, fully meeting the client’s requirements for productivity, quality, and operational reliability.

Plant Highlights and Technical Advantages

1. Robust and Efficient QT6-15 Block Making Machine

Heavy-duty frame manufactured from high-strength steel with precision welding ensures long-term stability under continuous operation.

Equipped with Japanese YUKEN hydraulic forming system and advanced vibration platform for high-density, high-strength products.

Hydraulic oil heating system ensures reliable operation during low-temperature winter conditions.

Siemens PLC control system enables intelligent operation, automatic fault diagnosis, and reliable process control.

2. Accurate and High-Performance Mixing System

JS500 forced concrete mixer ensures uniform material blending and accurate mix ratios.

Integrated water spray device automatically regulates the water–cement ratio, improving product consistency and surface finish.

3. Automated Stacking and Conveying System

Automatic block stacker and wet block conveyor ensure smooth product transfer and efficient stacking. Significantly reduces labor requirements while maintaining continuous production flow.

4. Automatic Pallet Provider

The automatic pallet provider ensures continuous and stable pallet feeding to the block making machine throughout the production process. By automatically supplying pallets at the correct timing and position, it eliminates manual pallet handling and prevents production interruptions caused by pallet shortages or misalignment.

This system significantly improves production continuity and operational efficiency, while reducing labor intensity and ensuring consistent forming quality.

5. Flexible Mould Options and High Production Capacity

The QT6-15 paver and curb stone making plant provides exceptional mould flexibility, supporting a wide range of pavers and curbstones:

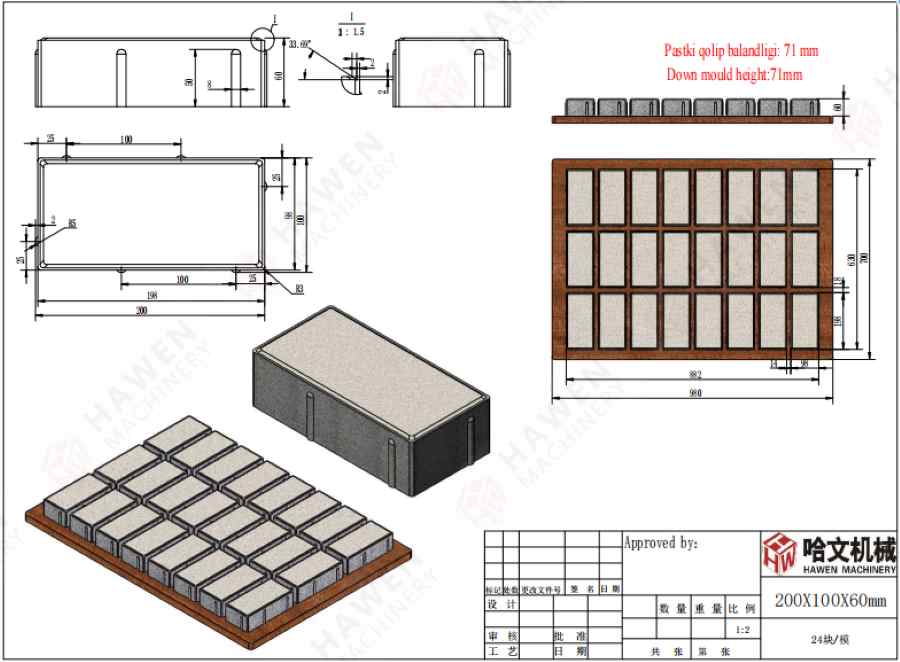

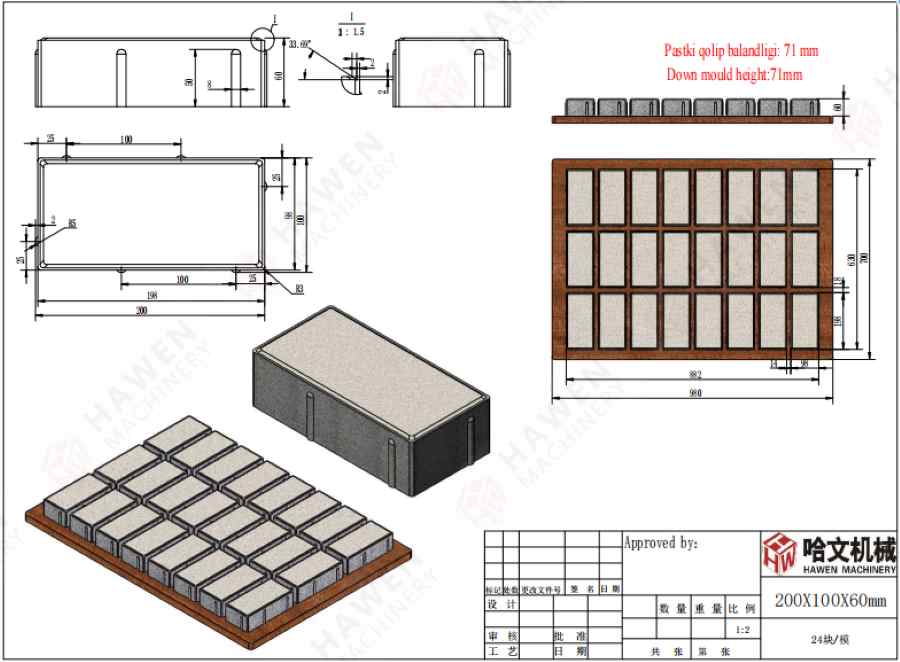

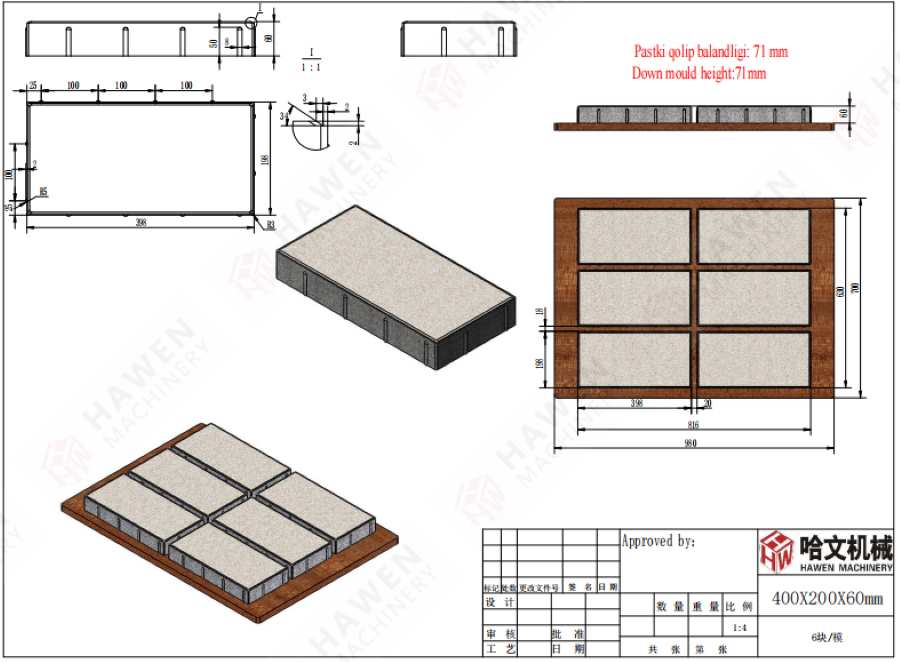

Standard rectangular pavers:

200 × 100 × 60 mm — 24 pcs/mould

200 × 200 × 60 mm — 12 pcs/mould

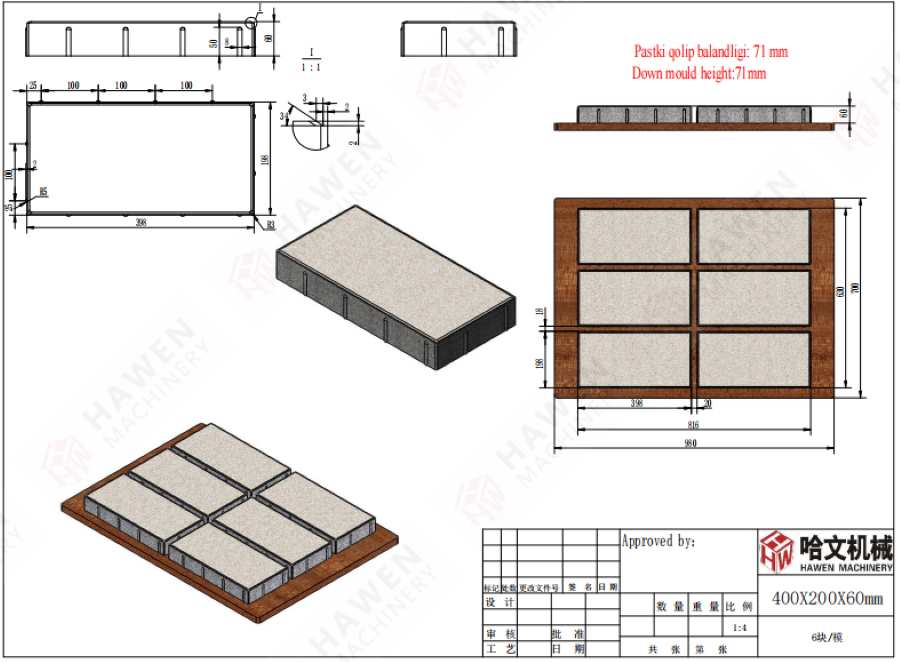

400 × 200 × 60 mm — 6 pcs/mould

Combination rectangular pavers:

180 × 120 × 40 mm

120 × 120 × 40 mm

120 × 90 × 40 mm

(each size: 10 pcs/mould)

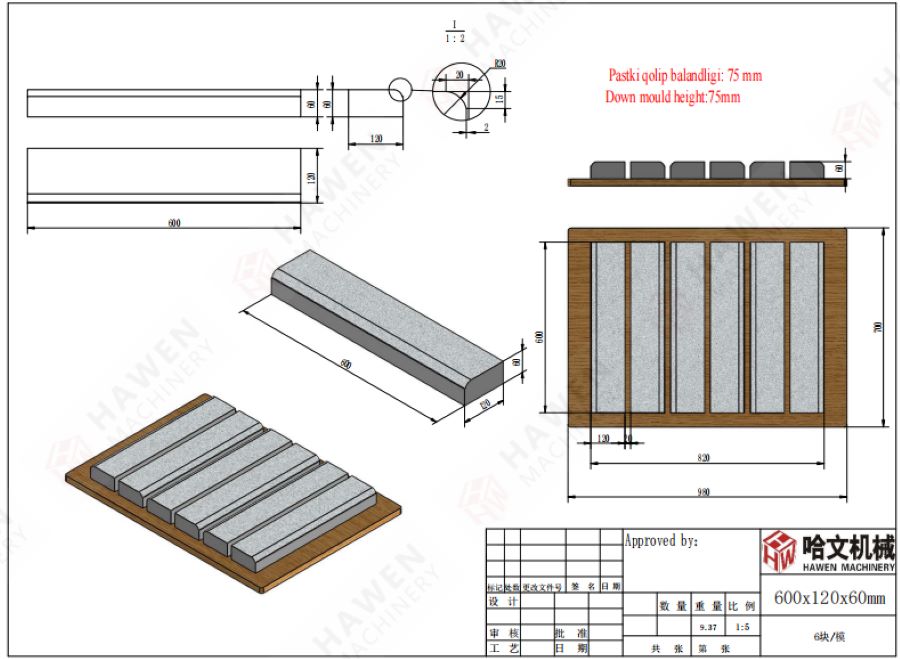

Curbstones:

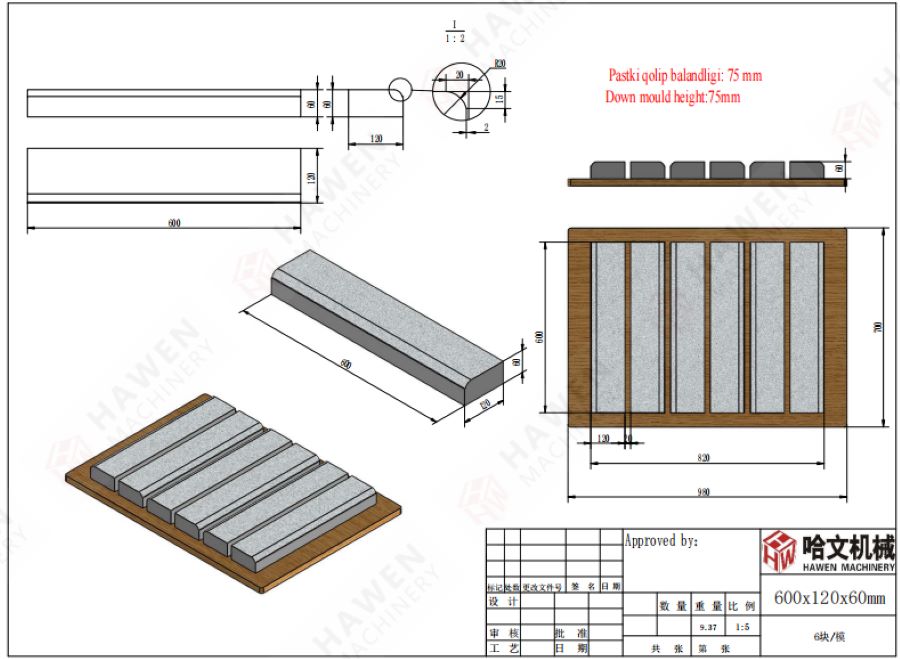

600 × 120 × 60 mm — 6 pcs/mould

With rapid mould change capability, the plant can also produce hollow blocks, solid bricks, pavers, and curbstones on the same production line.

Production capacity:

Depending on material composition, the plant can produce up to 35,000 pieces of 200 × 100 × 60 mm rectangular pavers or 9,000 pieces of 400 × 200 × 200 mm hollow blocks per 8-hour shift.

6.Enhanced Surface Finish

The water spray device provides a stone-like surface effect, enhancing both aesthetics and durability, making the products particularly suitable for premium paving and landscaping applications.

7.Energy Efficiency and Low Maintenance

Optimized hydraulic and vibration systems reduce energy consumption and mechanical wear.

Key components from Siemens and YUKEN ensure long-term reliability and ease of maintenance.

Client Feedback and Operational Confidence

After successful commissioning and stable operation, the client expressed strong satisfaction with the equipment and production results. They highlighted the robust machine design, intelligent PLC control system, and the consistent high quality of the finished products.

“The stability and precision of HAWEN's equipment give us full confidence. We plan to expand our production lines in the future and look forward to a long-term partnership with HAWEN.”

— Said by the factory General Manager, Mr. Tojie

Following the plant's successful start-up, the client organized a celebratory event to mark the launch of production, demonstrating their confidence and excitement for future operations.

7.Energy Efficiency and Low Maintenance

Optimized hydraulic and vibration systems reduce energy consumption and mechanical wear.

Key components from Siemens and YUKEN ensure long-term reliability and ease of maintenance.

Client Feedback and Operational Confidence

After successful commissioning and stable operation, the client expressed strong satisfaction with the equipment and production results. They highlighted the robust machine design, intelligent PLC control system, and the consistent high quality of the finished products.

“The stability and precision of HAWEN's equipment give us full confidence. We plan to expand our production lines in the future and look forward to a long-term partnership with HAWEN.”

— Said by the factory General Manager, Mr. Tojie

Following the plant's successful start-up, the client organized a celebratory event to mark the launch of production, demonstrating their confidence and excitement for future operations.

Future Outlook

With the QT6-15 paver and curb stone making plant now successfully running in Qarshi City, the client is well-positioned to meet growing demand for high-quality pavers and curbstones. This project further reinforces HAWEN MACHINERY's reputation as a reliable supplier of intelligent, high-performance block production systems.

HAWEN MACHINERY remains committed to supporting clients worldwide with advanced technology, rigorous quality assurance, and professional service, helping them establish efficient, sustainable, and competitive block production operations.

HAWEN MACHINERY — Engineering Precision, Reliability, and Innovation in Block Production.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China