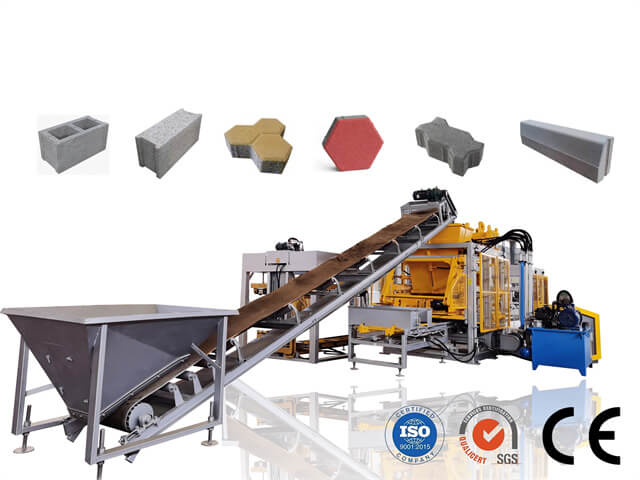

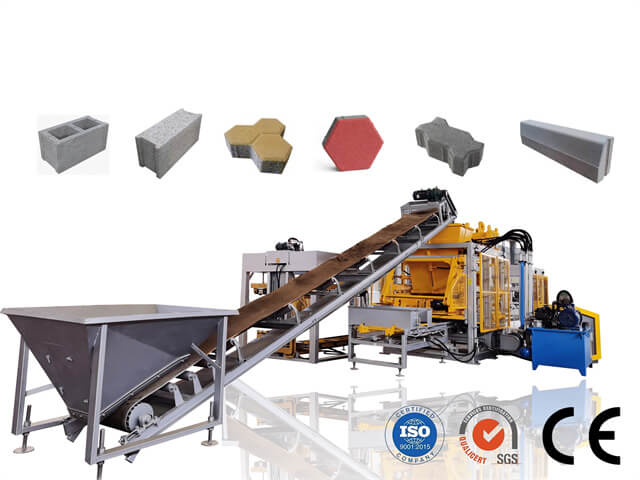

The Automatic Hollow Solid Cement Block Machine And Paver Production Line is a cutting-edge solution designed to meet the increasing demand for high-quality and efficient cement block and paver production. This innovative system integrates advanced technology to streamline the manufacturing process and enhance productivity.

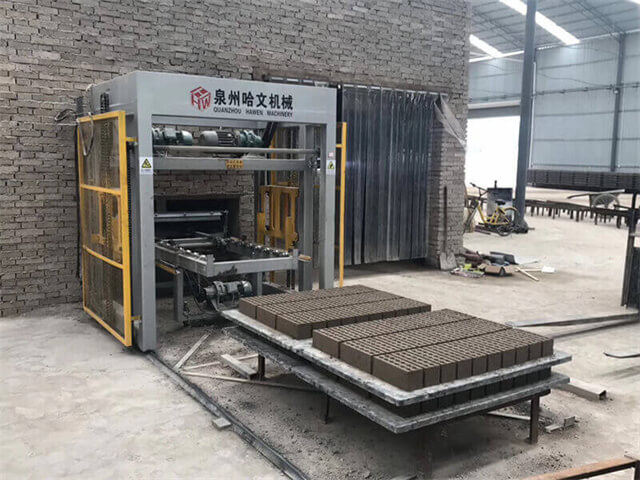

The size of pallet used in QT10-15 block making machine is 1100x950mm or 1200x900mm.

Technical Features:

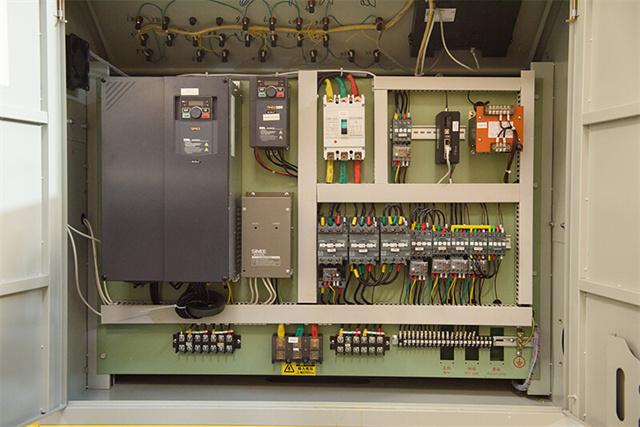

This production line features state-of-the-art automatic control systems, precision-engineered molds, and high-capacity material handling equipment. It utilizes hydraulic and pneumatic systems to ensure precise shaping and compacting of cement blocks and paver. The machine is equipped with a multi-functional control panel, allowing for easy adjustments and monitoring of the entire production process.

In conclusion, the Automatic Hollow Solid Cement Block Machine And Paver Production Line offers a comprehensive solution for modern cement block and paver production needs. Its advanced technology, high efficiency, and versatility make it a valuable asset for construction companies and manufacturers seeking to optimize their production processes and deliver superior-quality products.

Brick making flow chart introduction

|

NO.

|

Name of Machine

|

Note

|

|

1

|

Batching machine

|

Qty. Of strorage bin can be customized

|

|

2

|

Skip hoist for Concrete mixer

|

Another option: Conveyor belt

|

|

3

|

Cement scale

|

|

|

4

|

Screw conveyor

|

|

|

5

|

Cement Silo

|

Can be prepared by customer locally

|

|

6

|

Conveyor belt for aggregate material

|

|

|

7

|

Block making machine

|

|

|

8

|

Face material conveyor belt

|

|

|

9

|

Face material mixer

|

|

|

10

|

Automatic block stacker

|

|

|

11

|

Hydraulic station

|

|

|

12

|

Control system for batching and mixing

|

Optional

|

|

13

|

Control system for block machine

|

|

|

Note: It requires 1500-2000pcs of production pallet for production

|

High-speed and efficient production of various cement products- Precise shaping and compacting of blocks and pavers- Flexibility to produce different sizes and shapes of products- Energy-efficient operation with low maintenance requirements- Integration of advanced control systems for improved operational control and monitoring.

The Automatic Hollow Solid Cement Block Machine And Paver Production Line is suitable for producing a wide range of cement products, including hollow and solid blocks, interlocking pavers, and curbstones. It can be used in the construction of residential, commercial, and public infrastructure projects, providing durable and aesthetically pleasing building materials.

|

Capacity Sheet for QT10 Automatic block making plant

|

|

No.

|

Name

|

Dimension (mm)

( LxWxH)

|

Number of block per Pallet

|

Block /1hour

Estimated

|

Block /8hours

Estimated

|

|

1

|

Hollow block

|

400x200x200mm

|

10

|

1,800

|

14,400

|

|

2

|

Hollow block

|

400x150x200mm

|

12

|

2,160

|

17,280

|

|

3

|

Hollow block

|

400x100x200mm

|

18

|

3,200

|

25,600

|

|

4

|

Solid block

|

400x150x200mm

|

12

|

2,160

|

17,280

|

|

5

|

Solid brick

|

230x110x75mm

|

28

|

6,700

|

53,600

|

|

6

|

Solid brick

|

200x58x100mm

(198x58x100mm)

|

60

|

14,400

|

115,200

|

|

7

|

Stock brick

|

200x100x70mm

|

48

|

11,520

|

92,160

|

|

8

|

Holland Paver

|

200x100x60/80mm

|

36

|

6,480

|

51,840

|

|

9

|

H shape

paver

|

197x162x60/80mm

|

25

|

4,500

|

36,000

|

|

10

|

Hegzagonal Paver

|

228x198x60/80mm

|

18

|

3,200

|

25,600

|

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

The durability of this machine is impressive. It works hard every day and shows no signs of wear and tear. Love it!Jorge Jaime 2024-07-18

I have been using the QT10-15 cement brick making machine for over a year now, and it has never let me down. The output is consistent and the blocks are of top-notch quality. Highly recommended!2024-07-18

Compared to other machines in the market, the QT10-15 offers better value for money. We're happy with our purchase.Abayaraja Rathnathilaka 2024-07-18

QT10 Automatic Hollow Solid Cement Block Machine Paver Production Line has transformed our construction process. It's efficient, and reliable, and the blocks it produces have consistent quality, allowing us to deliver projects on time and to the highest standards.Evans Narh 2024-06-12