Description:

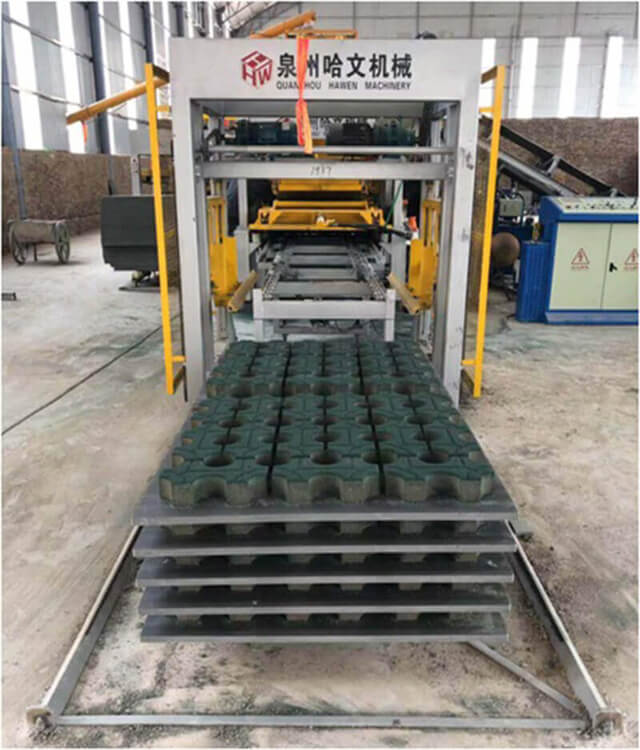

QT8-15 Automatic Concrete Paver Fly Ash Brick Making Machine is a cutting-edge construction equipment designed for efficiently producing high-quality bricks and pavers.

With the pallet size at 980x880mm.

It incorporates advanced technology and automation to streamline the manufacturing process, ensuring consistent results and enhanced productivity.

This versatile machine is suitable for producing a wide range of concrete products, making it an essential asset for construction projects of varying scales.

Technical Features:

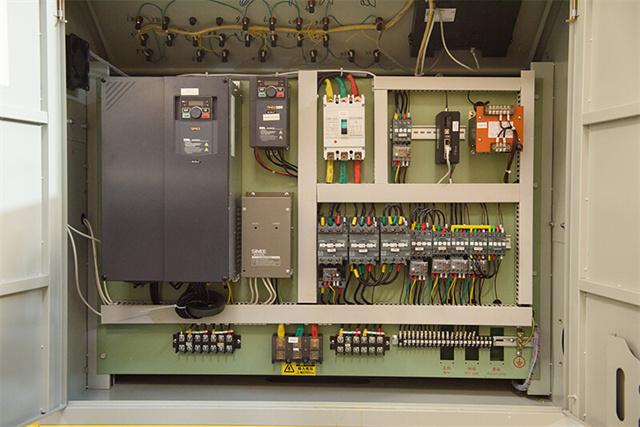

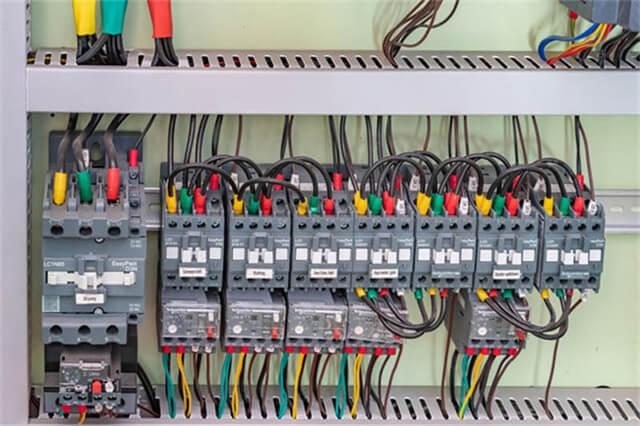

Equipped with state-of-the-art components and precision engineering, the Automatic Concrete Fly Ash Brick Making Machine And Paver offers numerous technical features that set it apart from conventional brick making machines.

Its automated operation, robust build, and intelligent control system enable seamless production with minimal manual intervention.

Additionally, its capacity to accommodate fly ash and concrete mixtures ensures sustainable and eco-friendly brick production, aligning with modern environmental standards.

Brick making flow chart introduction

|

NO.

|

Name of Machine

|

Note

|

|

1

|

Batching machine

|

Qty. Of strorage bin can be customized

|

|

2

|

Skip hoist for Concrete mixer

|

Another option: Conveyor belt

|

|

3

|

Cement scale

|

|

|

4

|

Screw conveyor

|

|

|

5

|

Cement Silo

|

Can be prepared by customer locally

|

|

6

|

Conveyor belt for aggregate material

|

|

|

7

|

Block making machine

|

|

|

8

|

Face material conveyor belt

|

|

|

9

|

Face material mixer

|

|

|

10

|

Automatic block stacker

|

|

|

11

|

Hydraulic station

|

|

|

12

|

Control system for batching and mixing

|

Optional

|

|

13

|

Control system for block machine

|

|

|

Note: It requires 1500-2000pcs of production pallet for production

|

Key Functions:

The Automatic Concrete Fly Ash Brick Making Machine And Paver offers a range of key functions that cater to the dynamic needs of the construction sector.

Its automatic material feeding, molding, and stacking capabilities ensure efficient and continuous production, reducing labor costs and maximizing output.

The machine's precision in shaping and compacting the concrete mixture results in high-quality finished products with consistent dimensions and strength.

Furthermore, its user-friendly interface and diagnostic features facilitate ease of operation and maintenance, enhancing overall usability and longevity.

In conclusion, the Automatic Concrete Fly Ash Brick Making Machine And Paver represents a significant advancement in brick and paver production technology, offering reliability, efficiency, and versatility to meet the demands of modern construction practices.

Its technical prowess, diverse application, and multifaceted functions position it as a pivotal tool for advancing construction projects with superior quality and productivity.

This innovative machine finds application in various construction projects, including residential, commercial, and industrial developments.

Its ability to produce different types and sizes of bricks and paver makes it suitable for applications such as building facades, pavements, driveways, and landscaping elements. Whether used by small-scale contractors or large construction companies, this machine is adaptable to diverse project requirements, making it a valuable asset for the construction industry.

|

Capacity Sheet for QT8 Automatic block making plant

|

|

No.

|

Name

|

Dimension (mm)

( LxWxH)

|

Number of block per Pallet

|

Block /1hour

Estimated

|

Block /8hours

Estimated

|

|

1

|

Hollow block

|

400x200x200mm

|

8

|

1,440

|

11,520

|

|

2

|

Hollow block

|

390x140x190mm

M140

|

12

|

2,160

|

17,280

|

|

3

|

Hollow block

|

400x100x200mm

|

14

|

2,500

|

20,000

|

|

4

|

Solid block

|

200x100x70mm

|

44

|

10,500

|

94,500

|

|

5

|

Square shape paver

|

250x250x60mm

|

9

|

1,620

|

12,960

|

|

6

|

Paver mould

|

200x100x60/80mm

|

32

|

5,700

|

45,600

|

|

7

|

Paver mould

|

200x100x60mm

|

32

|

5,700

|

45,600

|

|

8

|

Paver mould

|

200x160x60mm

|

20

|

3600

|

28,800

|

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

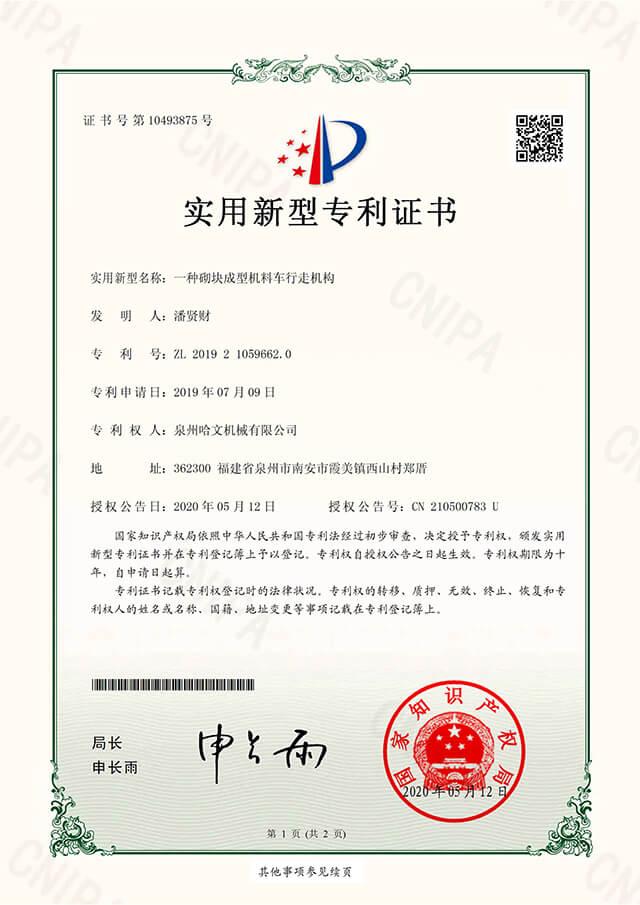

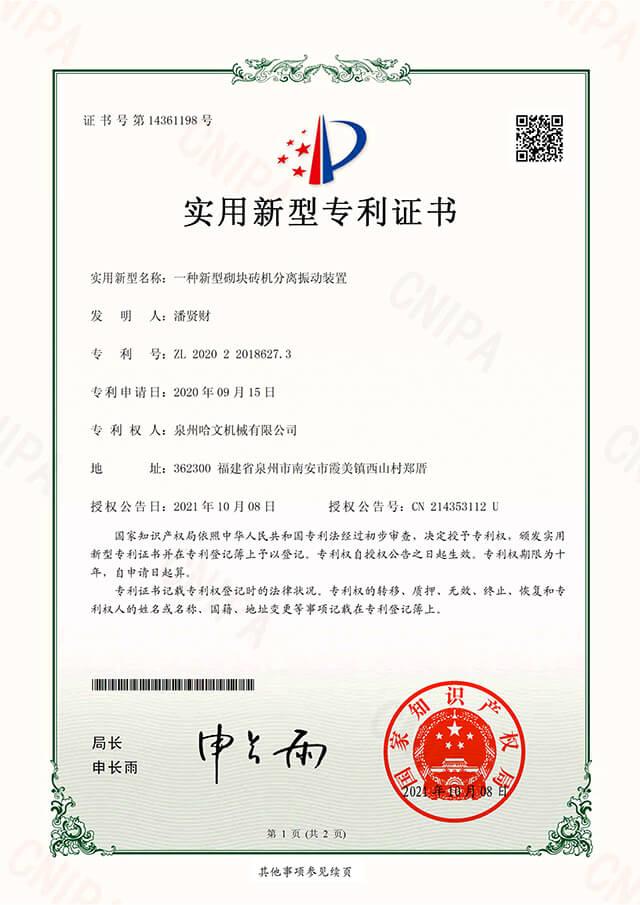

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

QT8 Automatic Concrete Paver Fly Ash Brick Making Machine is a good quality machine. We produced 2 shifts a day, the machine can work at heavy-duty condition with proper maintainence.B.Zolfagharpour 2024-06-12

Since we started using the QT8 Automatic Solid Cement Block Machine, our productivity has soared. It's a well-engineered machine that produces blocks precisely, allowing us to optimize our resources effectively.Matthew David 2024-07-20

The QT8 Automatic Solid Cement Block Machine has made our block production process seamless. It's reliable, easy to operate, and the blocks it produces have consistent strength, meeting our strict quality standards.Sophia W 2024-07-20

We are impressed with the performance of the QT8 Concrete Paving Blocks Machine. It has simplified our operations, improved productivity, and the blocks it produces are dimensionally stable, ensuring a perfect fit in our structures.Michelle H 2024-07-20