QT4-15 Automatic Cement Solid Brick Production Line Interlocking Paver Machine is a state-of-the-art industrial equipment designed for efficient and automated production of cement solid bricks and interlocking pavers,with the pallet size at 980x560mm,suitable for those who starts the block making business.

This advanced machine is equipped with cutting-edge technologies to streamline the manufacturing process and ensure high-quality output.

Technical Features:

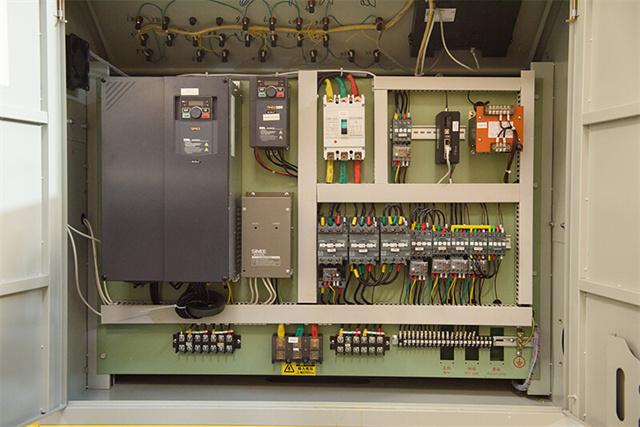

The machine is powered by advanced automation systems, featuring precise control mechanisms for accurate brick and paver production.

It integrates hydraulic and mechanical components for robust performance and is equipped with a user-friendly interface for easy operation and monitoring.

Additionally, it incorporates innovative mold designs for diverse brick and paver styles, offering flexibility in production capabilities.

Brick making flow chart introduction

|

NO.

|

Name of Machine

|

Note

|

|

1

|

Batching machine

|

Qty. Of strorage bin can be customized

|

|

2

|

Skip hoist for Concrete mixer

|

Another option: Conveyor belt

|

|

3

|

Cement scale

|

|

|

4

|

Screw conveyor

|

|

|

5

|

Cement Silo

|

Can be prepared by customer locally

|

|

6

|

Conveyor belt for aggregate material

|

|

|

7

|

Block making machine

|

|

|

8

|

Face material conveyor belt

|

|

|

9

|

Face material mixer

|

|

|

10

|

Automatic block stacker

|

|

|

11

|

Hydraulic station

|

|

|

12

|

Control system for batching and mixing

|

Optional

|

|

13

|

Control system for block machine

|

|

|

Note: It requires 1500-2000pcs of production pallet for production

|

The Automatic Cement Solid Brick Production Line Interlocking Paver Machine is widely utilized in construction material manufacturing plants, building material suppliers, and infrastructure development projects. Its versatile functionality allows for the production of a wide range of cement solid bricks and interlocking pavers, catering to various construction needs.

|

Capacity sheet for QT4 Automatic block making plant

|

|

No.

|

Name

|

Dimension (mm)

( LxWxH)

|

Number of block per Pallet

|

Block /1hour

Estimated

|

Block /8hours

Estimated

|

|

1

|

Hollow block

|

400x200x200mm

8inch

|

4

|

720

|

5,760

|

|

2

|

Hollow block

|

400x150x200mm

6inch

|

6

|

1,080

|

8,640

|

|

3

|

Hollow block

|

400x100x200mm

4inch

|

8

|

1,400

|

11,200

|

|

4

|

Solid brick

|

230x110x75mm

|

14

|

3,360

|

26,880

|

|

5

|

Square shape paver

|

250x250x60mm

|

6

|

1,080

|

8,640

|

|

6

|

Curb stone

|

500x300x150mm

|

1

|

180

|

1440

|

|

7

|

Zigzag Paver

|

200x100x60mm

|

16

|

2,800

|

22,400

|

|

8

|

Rectangular Paver

|

200x100x60mm

|

16

|

2,800

|

22,400

|

The primary functions of this machine include automatic feeding, compaction, and molding of cement mixtures to form solid bricks and interlocking pavers.

It ensures uniformity in size, shape, and density of the produced bricks and pavers, meeting industry standards. Furthermore, it offers a high production capacity, increasing operational efficiency and reducing manual labor requirements. Overall, the Automatic Cement Solid Brick Production Line Interlocking Paver Machine signifies a significant advancement in the construction material manufacturing sector, providing a reliable and efficient solution for meeting the demand for quality cement solid bricks and interlocking pavers.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

QT4 cement solid brick production line interlocking paver machine has exceeded our expectations in terms of quality and efficiency. It's a reliable workhorse that consistently delivers precise blocks, making our construction projects easier to executeJevon D 2024-06-12