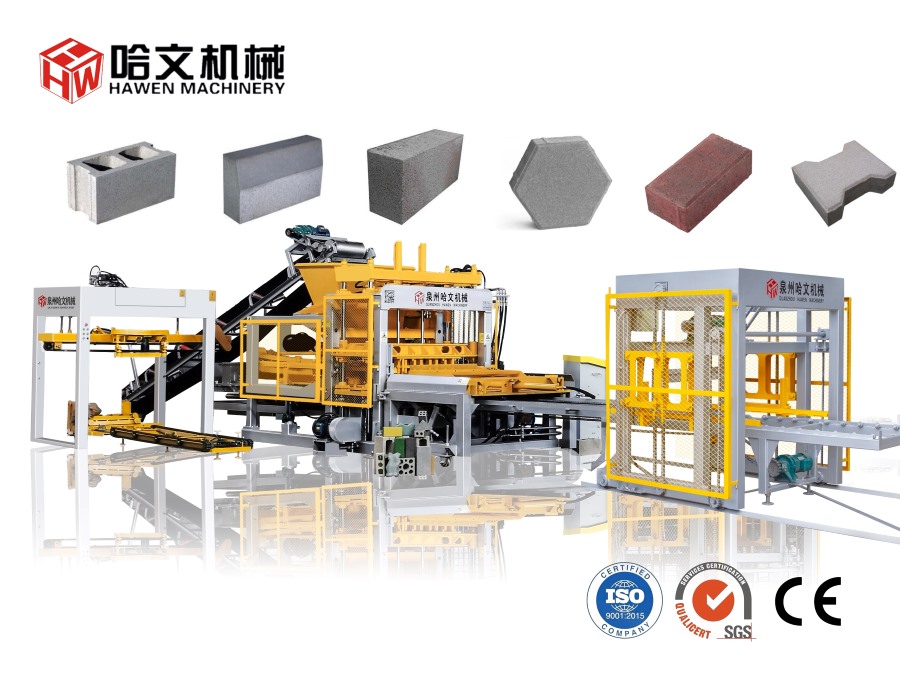

The QT7-15 Fully Automatic Hollow Block and Solid Brick Making Machine is a modern, high-performance equipment engineered for the efficient and automated production of various concrete masonry units. It belongs to the medium size category of block making machines, featuring a pallet size of 1150x750mm.

This advanced system integrates cutting-edge technology to optimize the production cycle, reduce manual labor, and ensure consistent, high-quality output. It is ideal for manufacturers seeking to boost productivity while maintaining precision and reliability in every brick and block produced.

Hydraulic System Overview:

The hydraulic system in QT7-15 block making machine consists of high-performance hydraulic pumps, valves, cylinders, and oil tanks designed to deliver consistent force and smooth operation.

This system provides the necessary pressure for compacting the concrete mixture inside the mold, ensuring high density and strength of the finished bricks or pavers. Advanced hydraulic control valves regulate flow and pressure precisely, improving cycle time and overall efficiency.

Additionally, the hydraulic components are engineered for energy efficiency, low noise, and minimal maintenance. With reliable hydraulic power, the machine achieves excellent molding performance, longer service life, and consistent product quality across various types of concrete blocks.

Mechanical System Overview:

The mechanical system of QT7-15 block making machine is responsible for the precise movement, alignment, and coordination of various production components. It includes robust steel frames, vibration tables, transmission shafts, gears, bearings, and guiding rails, all designed for durability and long-term stability.

This system ensures accurate positioning of the mold, smooth feeding of raw materials, and efficient vibration compaction. High-strength structural components minimize deformation under heavy loads, while precision machining guarantees consistent product dimensions.

The mechanical design also integrates wear-resistant materials and easy-to-maintain assemblies, reducing downtime and extending service life. Together with the hydraulic system, the mechanical system provides the stability, efficiency, and reliability needed for producing high-quality concrete blocks and pavers.

Technical Features:

The production system features high-end components including automatic batching systems, precise mixing equipment, and high-capacity block molding machines. It is equipped with intelligent control technology to monitor key production parameters and ensure stable, high-precision output. Designed with flexibility in mind, the machine is capable of producing a wide range of concrete products such as hollow blocks, solid bricks, and interlocking pavers, making a it suitable for a variety of building and landscaping applications.

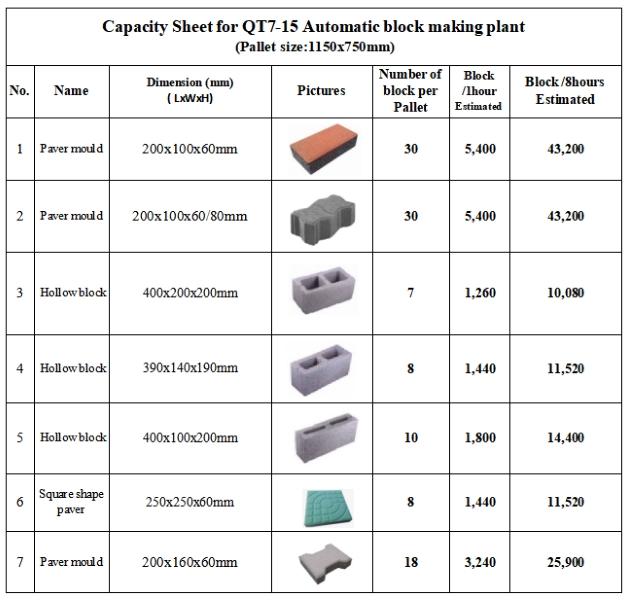

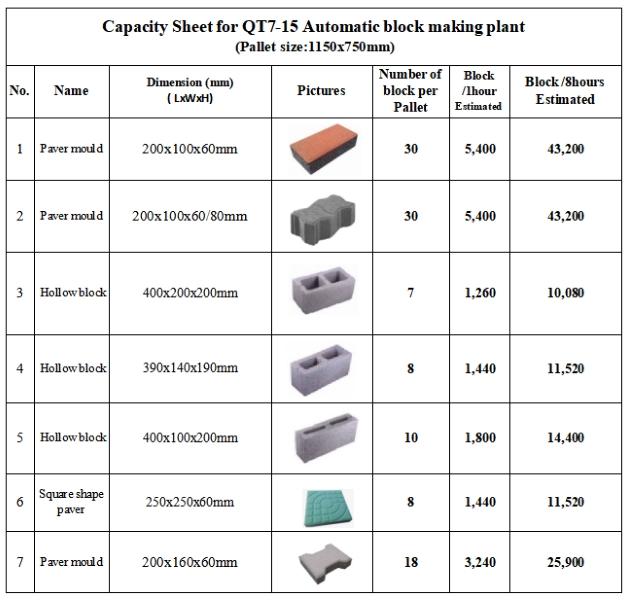

Capacity Sheet for QT7-15 Automatic block making plant:

Brick making flow chart introduction:

|

NO.

|

Name of Machine

|

Note

|

|

1

|

Batching machine

|

Qty. Of strorage bin can be customized

|

|

2

|

Skip hoist for Concrete mixer

|

Another option: Conveyor belt

|

|

3

|

Cement scale

|

|

|

4

|

Screw conveyor

|

|

|

5

|

Cement Silo

|

Can be prepared by customer locally

|

|

6

|

Conveyor belt for aggregate material

|

|

|

7

|

Block making machine

|

|

|

8

|

Face material conveyor belt

|

|

|

9

|

Face material mixer

|

|

|

10

|

Automatic block stacker

|

|

|

11

|

Hydraulic station

|

|

|

12

|

Control system for batching and mixing

|

Optional

|

|

13

|

Control system for block machine

|

|

|

Note: It requires 1500-2000pcs of production pallet for production

|

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China