-

1. Raw Material Preparation. 2. Grinding and Mixing. 3. Shaping and Compacting. 4. Cooling and Drying. 5. Cutting and Finishing. 6. Quality Control. 7. Packagin...

Block Machine

-

Step 1: Site Preparation. Step 2: Setting the Base. Step 3: Mounting the Machine Frame. Step 4: Attaching the Hydraulic System. Step 5: Installing the Screed. S...

Hydraulic Paver Machine

-

Step 1: Preparing the Site. Step 2: Assembling the Machine. Step 3: Testing and Calibration. Step 4: Routine Maintenance. Step 5: Cleaning. Step 6: Replacement ...

EPS Block Moulding Machine

-

1. Regular Maintenance. 2. Lubrication. 3. Troubleshooting. 4. Training. 5. Documentation. 6. Spare Parts. 7. After-Sales Service Support. 8. Preventive Mainten...

Henry Block Machine

-

Introduction. 1. Site Preparation. 2. Machine Assembly. 3. Electrical Connection. 4. Mechanical Calibration. 5. Lubrication and Maintenance Schedule. 6. Safety ...

Pallet Block Machine

-

1. Selecting the Right Location. 2. Preparing the Ground. 3. Setting Up the Machine. 4. Connecting Power and Utilities. 5. Testing and Calibration. 6. Regular C...

Solid Block Machine

-

1. Setting Up the Machine. 2. Assembly and Connection. 3. Testing and Calibration. 4. Routine Inspection. 5. Lubrication and Cleaning. 6. Preventive Maintenance...

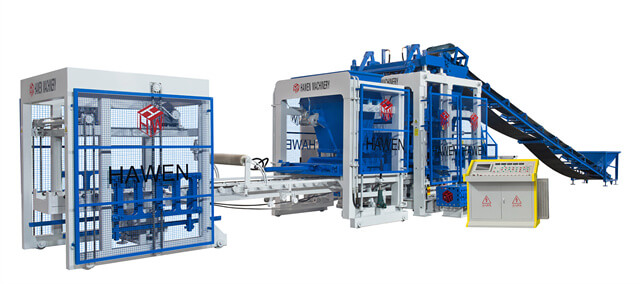

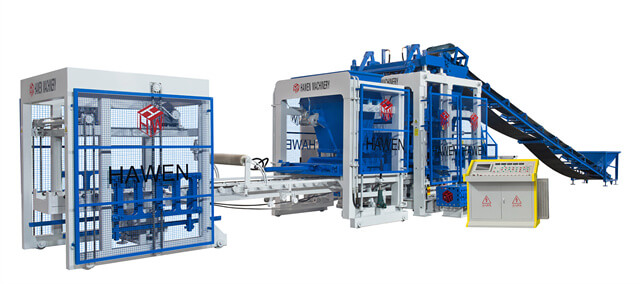

concrete block making machine

-

1. Installation Process. 2. Electrical Connections. 3. Hydraulic System Setup. 4. Mold Selection and Alignment. 5. Material Preparation. 6. Machine Calibration ...

Block Machine

-

1. Machine Design. 2. Raw Material Selection. 3. Automation. 4. Quality Control. 5. Energy Efficiency. 6. Training and Skilled Workforce. 7. Continuous Improvem...

Industrial Block Making Machine

-

Installation. Foundation. Startup and Operation. Maintenance. Troubleshooting. Safety Precautions. Environmental Protection. Conclusion....

Hydraulic Block Making Machine

-

1. Site Preparation. 2. Foundation Construction. 3. Machine Assembly. 4. Electrical and Hydraulic Connections. 5. Testing and Calibration. 6. Regular Cleaning a...

Industrial Block Making Machine

-

1. Equipment Setup. 2. Electrical and Hydraulic Connections. 3. Startup and Testing. 4. Regular Maintenance. 5. Troubleshooting. 6. Safety Precautions. 7. Clean...

Hollow Block Moulding Machine

-

1. Proper Machine Setup. 2. Quality Control of Raw Materials. 3. Optimal Block Design. 4. Regular Maintenance and Cleaning. 5. Streamlined Production Workflow. ...

Hollow Block Machine

-

1. Introduction to the Henry Block Machine. 2. Automated Mixing and Feeding System. 3. Quick and Efficient Molding Process. 4. Versatile Block Designs and Sizes...

Henry Block Machine

-

Understanding the Components. Preparation and Site Selection. Assembling the Machine. Electrical Connection and Testing. Operational Training. Maintenance and T...

lock Making Machine

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China