-

1. Comprehensive After-Sales Service. 2. Prompt Response and Timely Solutions. 3. Training and Technical Support. 4. Continuous Technological Innovation. 5. Imp...

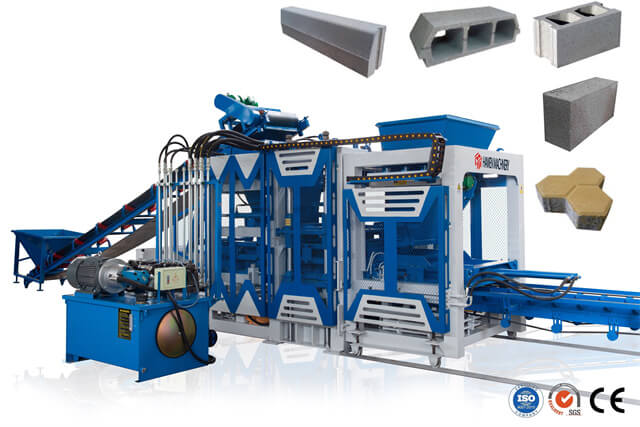

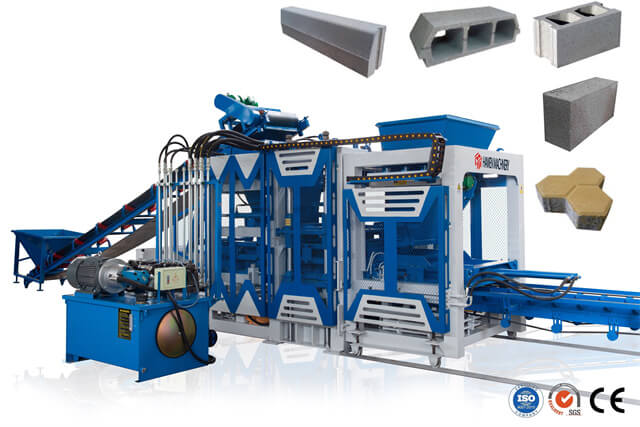

Block Machine

-

1. Increased Efficiency. 2. Versatility in Block Sizes and Shapes. 3. Consistent Block Quality. 4. Cost-effective Solution. 5. User-friendly Operation. 6. Durab...

Block Moulding Machine

-

1. Introduction to Manual Concrete Block Machines. 2. Operating Principles of Manual Concrete Block Machines. 3. Components of Manual Concrete Block Machines. 4...

Manual Concrete Block Machine

-

Introduction. 1. High Production Capacity. 2. Consistent Quality. 3. Versatility in Design. 4. Cost-Efficiency. 5. Time-Saving. 6. Durability. 7. Energy Efficie...

Brick and Block Machine

-

.jpg)

1. The Pressure System. 2. The Mixing System. 3. The Molding System. 4. The Vibrating System. 5. The Curing System. 6. The Stacking System. 7. The Electric Cont...

Building Block Machines

-

1. High Efficiency. 2. Energy-efficient. 3. Precision Engineering. 4. Versatility. 5. Cost-effective. 6. Excellent Insulation properties. 7. Fire and Pest Resis...

AAC Block Making Machine

-

Structure of Manual Block Making Machine. Block Making Process. Block Sizes and Shapes. Advantages of Manual Block Making Machines. Disadvantages of Manual Bloc...

Manual Block Making Machine

-

Early Development. Integration of Advanced Technologies. Modern Design Principles. Working Principle: Raw Material Preparation. Working Principle: Block Formati...

Automatic Block Making Machine

-

1. Introduction to Besser Block Machines. 2. Early Development of Besser Block Machines. 3. Technological Advancements. 4. Varied Machine Configurations. 5. Env...

Besser Block Machines

-

Introduction. 1. Understanding Cinder Block Machine Components. 2. Proper Machine Setup. 3. Quality Control Measures. 4. Efficient Raw Material Management. 5. C...

cinder block making machine

-

1. Understanding the Machine. 2. Types of Cinder Blocks. 3. The Cinder Block Making Process. 4. Ensuring Quality Control. 5. Safety Precautions. 6. Increasing P...

Cinder Block Making Machine

-

Introduction. 1. Origins of Cinder Blocks. 2. Introduction of Mechanical Molds. 3. Vibrating Technology. 4. Reinforcement Options. 5. Automation and Computeriza...

Cinder Block Making Machine

-

Evolution of Paver Block Manufacturing Machines. Working Principle of Paver Block Manufacturing Machines. Advantages of Paver Block Manufacturing Machines. Appl...

Paver Block Manufacturing Machines

-

1. Raw Material Preparation. 2. Feeding and Mixing. 3. Block Formation. 4. Curing and Drying. 5. Block Stacking and Handling. 6. Quality Control. 7. Automation ...

brick making machine

-

Evolution of CEB Press. Working Principles. Advantages of CEB Press. Challenges and Innovations. Applications in Sustainable Development. Future Trends. Conclus...

brick making machine

.jpg)

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China