How Block Machines Convert Raw Materials into Finished Blocks

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-01-13

How Block Machines Convert Raw Materials into Finished Blocks

Concrete block machines play a vital role in modern construction by transforming basic raw materials into durable, uniform building blocks. Understanding this process not only helps buyers make informed decisions but also highlights why quality machinery is essential for consistent production. Below is a clear, step-by-step overview of how block machines work from start to finish.

1. Raw Material Preparation

The process begins with the careful selection of raw materials, which typically include:

Primary materials: cement, sand, and crushed stone or gravel (maximum 10 mm)

Supplementary materials: stone powder, coal fly ash, cinder, slag, gangue, gravel, and other industrial by-products

Water, which is essential for cement hydration

Optional chemical admixtures, such as accelerating agents, superplasticizers, air-entraining agents, and shrinkage-reducing agents

For top-colored paving stones, additional surface materials such as fine sand, white cement, and pigments are incorporated

Each material must meet specific quality standards. The correct proportion of these ingredients directly affects block strength, density, and appearance.

2. Precise Batching and Mixing

Once selected, the materials are measured through a batching system. Accuracy at this stage is critical.

Aggregates and cement are weighed according to the mix design

Water and additives are added in controlled amounts

All components are mixed thoroughly to form a uniform concrete mixture

A well-mixed material ensures consistent block quality and reduces defects during molding.

3. Feeding into the Block Machine

The prepared concrete mix is then transferred to the block making machine via conveyor belt.

Inside the machine:

The mix is evenly distributed into the mould

Sensors or mechanical systems ensure correct filling levels

This step ensures that each block has uniform size and weight.

4. Molding and Compaction

Aggregates and cement are weighed according to the mix design

Water and additives are added in controlled amounts

All components are mixed thoroughly to form a uniform concrete mixture

A well-mixed material ensures consistent block quality and reduces defects during molding.

3. Feeding into the Block Machine

The prepared concrete mix is then transferred to the block making machine via conveyor belt.

Inside the machine:

The mix is evenly distributed into the mould

Sensors or mechanical systems ensure correct filling levels

This step ensures that each block has uniform size and weight.

4. Molding and Compaction

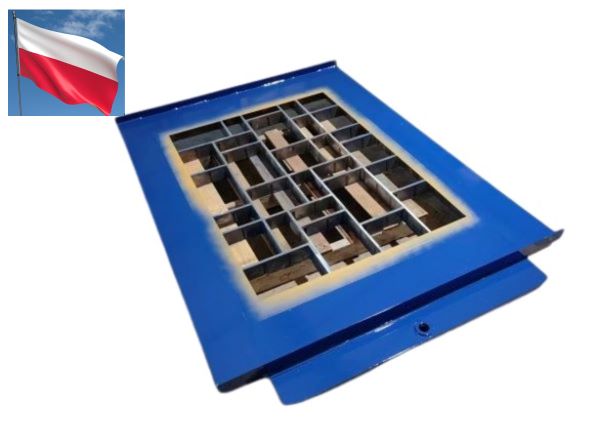

This is the core stage of block production.

The mould shapes the concrete into blocks

Vibration systems remove air pockets

Hydraulic or mechanical pressure compacts the material

The combination of vibration and pressure increases block density, strength, and surface finish.

5. Demoulding and Green Block Formation

After compaction:

The mould is lifted

Freshly formed “green blocks” are released onto pallets

At this stage, the blocks are not fully hardened and must be handled carefully to avoid damage.

6. Curing for Strength Development

Curing is essential for achieving the required block strength.

Common curing methods include:

Natural curing in a shaded area

Steam curing chambers for faster strength gain

Controlled humidity and temperature environments

Proper curing allows cement hydration to continue, significantly improving durability and load-bearing capacity.

7. Stacking and Packaging

This is the core stage of block production.

The mould shapes the concrete into blocks

Vibration systems remove air pockets

Hydraulic or mechanical pressure compacts the material

The combination of vibration and pressure increases block density, strength, and surface finish.

5. Demoulding and Green Block Formation

After compaction:

The mould is lifted

Freshly formed “green blocks” are released onto pallets

At this stage, the blocks are not fully hardened and must be handled carefully to avoid damage.

6. Curing for Strength Development

Curing is essential for achieving the required block strength.

Common curing methods include:

Natural curing in a shaded area

Steam curing chambers for faster strength gain

Controlled humidity and temperature environments

Proper curing allows cement hydration to continue, significantly improving durability and load-bearing capacity.

7. Stacking and Packaging

Once cured:

Blocks are stacked manually or by automatic cuber system and strapping

Palletizing systems may be used for higher efficiency

Finished blocks are prepared for storage or shipment

Automation at this stage reduces labor costs and minimizes breakage.

8. Quality Control and Inspection

Before delivery, blocks are checked for:

Dimensions and shape consistency

Surface finish

Compressive strength

Reliable block machines help maintain stable quality across large production volumes.

Once cured:

Blocks are stacked manually or by automatic cuber system and strapping

Palletizing systems may be used for higher efficiency

Finished blocks are prepared for storage or shipment

Automation at this stage reduces labor costs and minimizes breakage.

8. Quality Control and Inspection

Before delivery, blocks are checked for:

Dimensions and shape consistency

Surface finish

Compressive strength

Reliable block machines help maintain stable quality across large production volumes.

Conclusion

From raw materials to finished products, block machines combine precise batching, powerful compaction, and controlled curing to produce strong, uniform concrete blocks. Investing in the right block making machine not only improves efficiency but also ensures consistent quality, helping manufacturers meet market demands and construction standards with confidence.

Conclusion

From raw materials to finished products, block machines combine precise batching, powerful compaction, and controlled curing to produce strong, uniform concrete blocks. Investing in the right block making machine not only improves efficiency but also ensures consistent quality, helping manufacturers meet market demands and construction standards with confidence.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China