What Types of Concrete Products Can a Block Making Machine Produce?

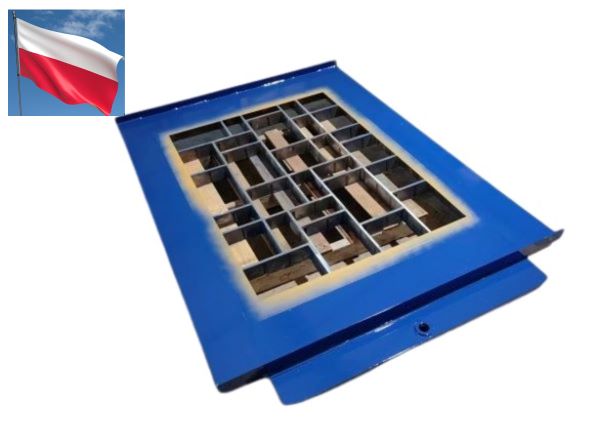

Modern block making machines are designed to deliver efficiency, precision, and production flexibility. By changing moulds and adjusting configurations, a single machine can manufacture a wide variety of concrete products for building construction, roadworks, landscaping, and municipal infrastructure.

While the most commonly produced and commercially significant products include concrete blocks, concrete pavers, curb stones, and specialty concrete units, these machines are highly versatile and can produce customized shapes and sizes depending on the moulds used.

1. Concrete Blocks

Concrete blocks are structural masonry units used for walls, foundations, and columns. They can be divided into:

Hollow Blocks: Lightweight blocks with internal cavities, reducing material use and making handling easier. Thermal and acoustic insulation can be achieved when foam or insulating material is added.

Solid Blocks: Dense, high-strength blocks suitable for load-bearing applications.

Solid Blocks: Dense, high-strength blocks suitable for load-bearing applications.

Typical applications: Residential, commercial, and industrial walls, foundations, and structural columns.

2. Concrete Pavers

Concrete pavers are modular units designed for walkways, driveways, plazas, and industrial pavements. They include:Rectangle paver, H-shape paver, Zigzag Paver, concrete slab, etc..

Rectangle Pavers: Standard rectangular units for general paving.

Country-specific names: Cabro (Kenya), Bevel Paver (South Africa)

Typical applications: Residential, commercial, and industrial walls, foundations, and structural columns.

2. Concrete Pavers

Concrete pavers are modular units designed for walkways, driveways, plazas, and industrial pavements. They include:Rectangle paver, H-shape paver, Zigzag Paver, concrete slab, etc..

Rectangle Pavers: Standard rectangular units for general paving.

Country-specific names: Cabro (Kenya), Bevel Paver (South Africa)

H-shape Pavers: Interlocking pavers shaped like an “H” for enhanced mechanical stability.

H-shape Pavers: Interlocking pavers shaped like an “H” for enhanced mechanical stability.

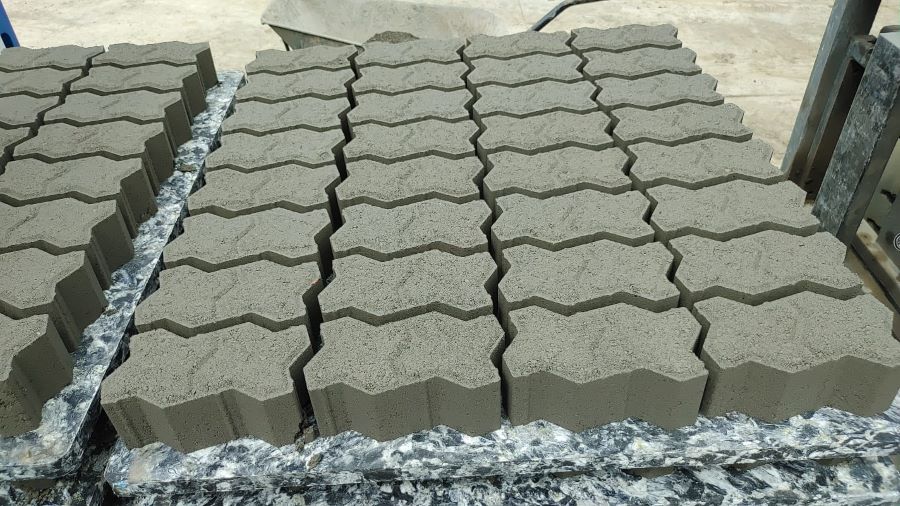

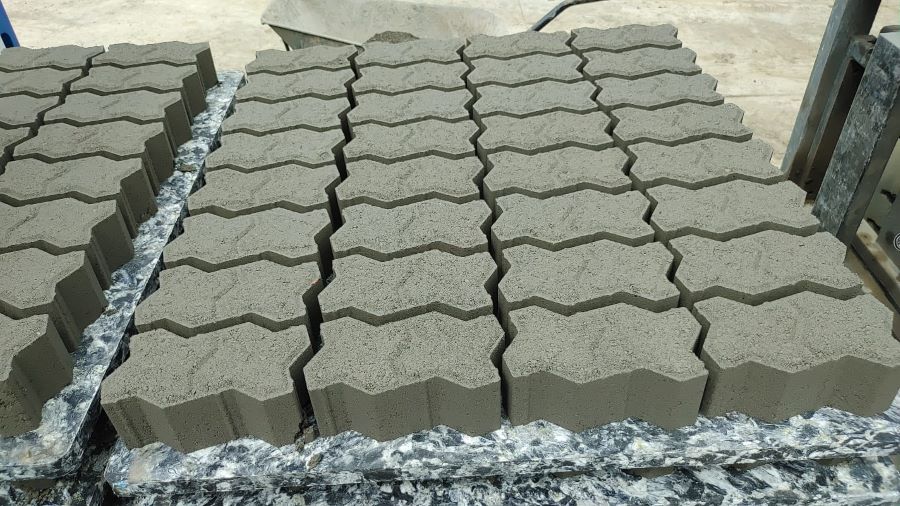

Zigzag Pavers: Interlocking units with a zigzag pattern, commonly used for roads and industrial yards.

Zigzag Pavers: Interlocking units with a zigzag pattern, commonly used for roads and industrial yards.

Concrete Slabs: Large, flat units for heavy-duty applications or decorative landscaping.

Typical applications: Sidewalks, driveways, plazas, parking areas, and industrial floors.

3. Curb Stones

Curb stones are linear concrete elements used to define, separate, and protect paved areas.

Key features:

High strength and impact resistance

Precise dimensions for consistent alignment

Long service life in outdoor and high-traffic environments

Typical applications: Road edges, sidewalks, parking lots, and municipal infrastructure projects.

Concrete Slabs: Large, flat units for heavy-duty applications or decorative landscaping.

Typical applications: Sidewalks, driveways, plazas, parking areas, and industrial floors.

3. Curb Stones

Curb stones are linear concrete elements used to define, separate, and protect paved areas.

Key features:

High strength and impact resistance

Precise dimensions for consistent alignment

Long service life in outdoor and high-traffic environments

Typical applications: Road edges, sidewalks, parking lots, and municipal infrastructure projects.

4. Specialty & Custom Concrete Products

With the appropriate moulds, block making machines can also produce:

Decorative bricks

Interlocking pavers with custom profiles

Slabs and kerbstones with special shapes

Other customized concrete units for architectural or industrial applications

These products allow manufacturers to expand their product range and meet diverse market demands.

Conclusion

A block making machine is not limited to the four main product types. It can produce a wide range of concrete blocks, pavers, slabs, kerbstones, and customized units depending on the moulds used.

By focusing on hollow blocks, solid blocks, rectangular pavers, and curb stones as their core products, manufacturers can reliably meet essential construction and infrastructure demands, while the exceptional flexibility of modern block making machines empowers them to diversify their product range, swiftly respond to evolving market needs, and achieve optimal production efficiency without compromising quality.

4. Specialty & Custom Concrete Products

With the appropriate moulds, block making machines can also produce:

Decorative bricks

Interlocking pavers with custom profiles

Slabs and kerbstones with special shapes

Other customized concrete units for architectural or industrial applications

These products allow manufacturers to expand their product range and meet diverse market demands.

Conclusion

A block making machine is not limited to the four main product types. It can produce a wide range of concrete blocks, pavers, slabs, kerbstones, and customized units depending on the moulds used.

By focusing on hollow blocks, solid blocks, rectangular pavers, and curb stones as their core products, manufacturers can reliably meet essential construction and infrastructure demands, while the exceptional flexibility of modern block making machines empowers them to diversify their product range, swiftly respond to evolving market needs, and achieve optimal production efficiency without compromising quality.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China