QT18 Fully Automatic Block Production Line with Curing Chamber

Experience cutting-edge automation in block manufacturing with HAWEN Machinery's QT18 Fully Automatic Concrete Block Production Line, designed for high-efficiency, high-output production environments.

✅Key Features of the QT18 Fully Automatic Line:

1.High Output Moulding Capacity: Produces 100 solid bricks per mould, ideal for large-scale production, for 8inch hollow block 400x200x200mm at 18pcs per mould, for 6inch hollow block at 24pcs per mould.

2.Large Pallet Size: 1400×1300mm, providing a stable and spacious platform for forming diverse concrete products.

3.Automatic Forming System: Ensures uniform compaction and vibration for high-strength block shaping.

✅Complete Intelligent Workflow:

1.Automatic batching and mixing system

1️⃣ Raw Material Loading

-

Materials such as sand, cement, stone chips, and additives are loaded into the hoppers using a wheel loader, feeding the plant efficiently and continuously.

2️⃣ Automatic Batching System

-

All raw materials are automatically weighed and proportioned according to preset formulas for different block types.

-

Ensures consistency, reduces waste, and supports multi-recipe production.

3️⃣ Automatic Mixing System

-

High-efficiency mixers combine the materials to produce a uniform concrete mix, optimized for strength, flowability, and vibration compatibility.

4️⃣ Material Conveying

2.Automatic Forming System – The production begins with precision forming on robust 1400×1300mm pallets.

3.Automatic Elevator – Elevates the stacked green blocks to the Finger Cart loading height.

4.Finger Cart Operation - Transports wet concrete blocks from the elevator directly into the Curing Chamber.

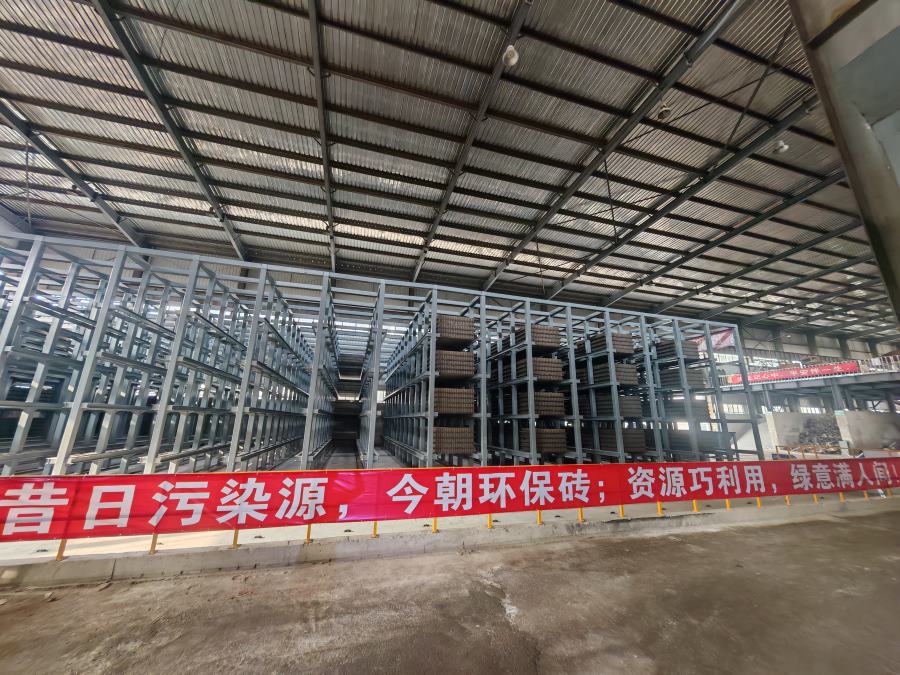

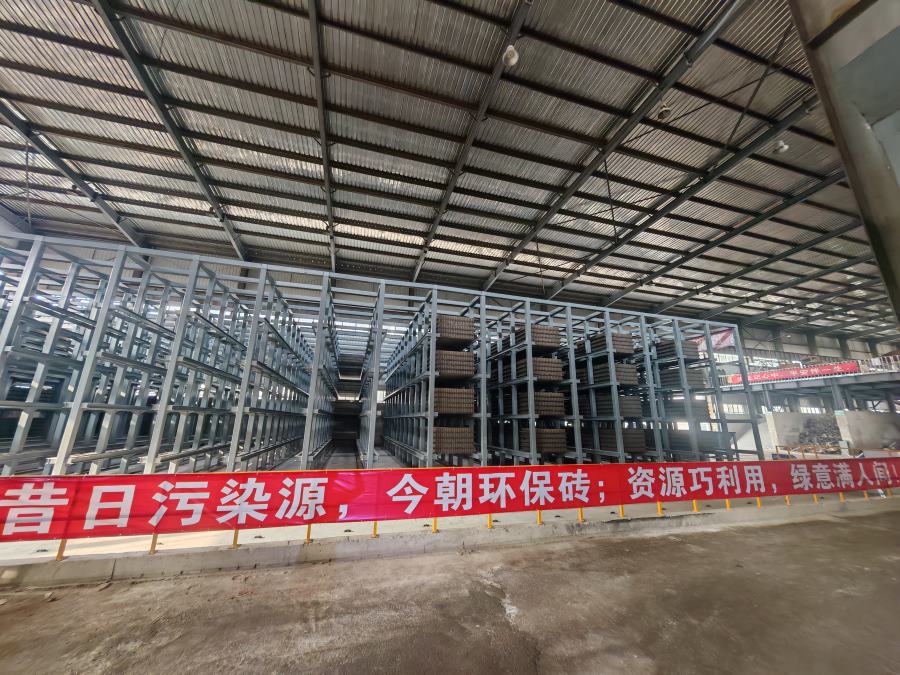

5.After the curing cycle, the Finger Cart re-enters the chamber and retrieves the cured blocks.

6.Automatic Lowerator – Brings the cured blocks down to the line for the next phase.

7.Automatic Pallet Turnover System – Recycles empty pallets back to the forming machine, maintaining continuous production.

8.Automatic Cuber System – Arranges the cured blocks into bundles with precision and stability.

9.Automatic Strapping Machine – Applies heavy-duty strapping to secure each cube for transport and storage.

10.Automatic Soaking Machine – Enhances final product quality by applying controlled moisture as needed.

11.Forklift Transfer to Stock Yard – Finished and packaged blocks are transported efficiently to the stock yard.

✅System Advantages:

1.Minimal manual labor

2.High precision and uniformity

3.Reduced waste and downtime

4.Energy-efficient curing and automation

5.Scalable for large production demands

✅Applications:

Perfect for the production of:

1.Solid Bricks

2.Paving Stones

3.Hollow Blocks

4.Interlocking Blocks

5.Curbstones & More

✅Why Choose HAWEN Machinery?

HAWEN Machinery stands out as a trusted manufacturer and solution provider in the concrete block machinery industry. With decades of experience and a commitment to innovation, we deliver turnkey solutions that help our clients boost efficiency, reduce labor costs, and achieve stable, high-volume production.

Here's why leading producers around the world choose HAWEN:

1.Robust Engineering: All machines are built with high-strength steel structures and premium components for durability and long service life.

2.German Technology Integration: Advanced hydraulic systems, PLC controls, and modular automation are inspired by top European standards.

3.Custom Solutions: Each production line can be tailored to meet specific block types, pallet sizes, and capacity needs.

4.Global Support & Service: From installation to training and after-sales support, our professional team is with you every step of the way.

5.Energy Efficiency & Smart Control: Our fully automatic systems use intelligent sensors and software to optimize every stage of production.

Choose HAWEN, and you’re not just investing in machinery — you’re partnering with a team dedicated to your long-term success.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China