How Hydraulic Systems Work in Block Machines

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-01-17

How Hydraulic Systems Work in Block Machines

In modern block production, hydraulic systems are the backbone of high-efficiency, high-precision operations. At Hawen Machinery, our block machines integrate advanced hydraulic components to ensure consistent block quality, high productivity, and long-term reliability. Understanding the structure, components, and working principles of these systems demonstrates why hydraulic technology is indispensable in contemporary block manufacturing.

1. The Role of the Hydraulic System

The hydraulic system in a block machine converts pressurized fluid into controlled mechanical force. Unlike purely mechanical systems, hydraulic systems provide smooth, adjustable, and synchronized motion for:

Compressing concrete or mortar uniformly

Moving molds and pallets with precision

Lifting and discharging blocks without damage

These capabilities ensure uniform block density, high dimensional accuracy, and stable, repeatable production, which are critical for high-quality construction materials. Importantly, modern hydraulic systems allow operators to control both force and speed simultaneously, optimizing production efficiency and minimizing material waste.

1. The Role of the Hydraulic System

The hydraulic system in a block machine converts pressurized fluid into controlled mechanical force. Unlike purely mechanical systems, hydraulic systems provide smooth, adjustable, and synchronized motion for:

Compressing concrete or mortar uniformly

Moving molds and pallets with precision

Lifting and discharging blocks without damage

These capabilities ensure uniform block density, high dimensional accuracy, and stable, repeatable production, which are critical for high-quality construction materials. Importantly, modern hydraulic systems allow operators to control both force and speed simultaneously, optimizing production efficiency and minimizing material waste.

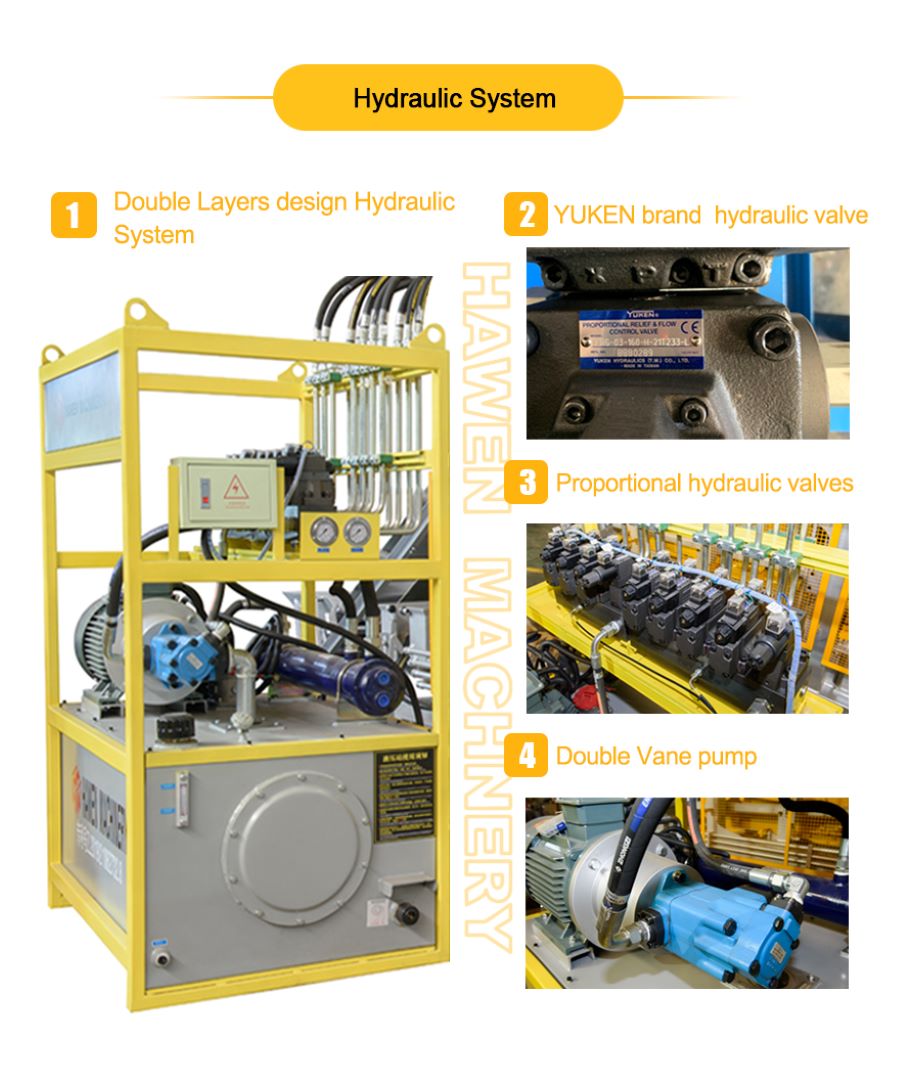

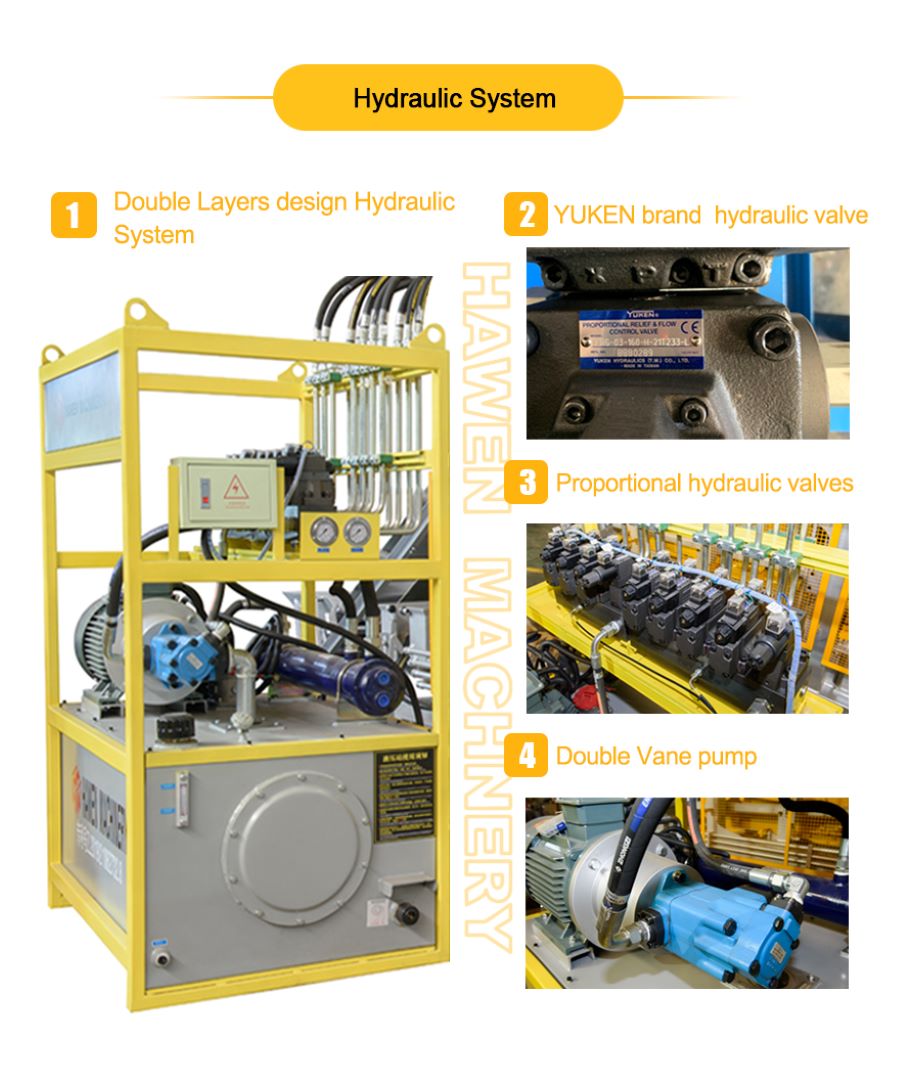

2. Core Components of the Hydraulic System

At Hawen Machinery, the hydraulic station of our block machines adopts Japanese YUKEN proportional and directional valves and an American ALBERT hydraulic pump, combining precise control with high load capacity and long-term durability. The system’s core components include:

a) Hydraulic Pump (ALBERT)

The ALBERT hydraulic pump converts mechanical energy into hydraulic pressure, supplying power to the entire system. Key features and components include:

Pump body: Houses internal rotating parts and withstands high pressure

Rotating elements (piston, gear, or vane): Convert mechanical motion into hydraulic flow

Gear pumps: Simple and cost-effective for medium/low-pressure applications

Piston pumps: High efficiency, suitable for high pressure and large flow rates

Vane pumps: Provide smooth flow with low noise

Bearings and seals: Ensure smooth rotation and prevent leakage

Inlet and outlet ports: Connect to hydraulic circuits for fluid input and output

2. Core Components of the Hydraulic System

At Hawen Machinery, the hydraulic station of our block machines adopts Japanese YUKEN proportional and directional valves and an American ALBERT hydraulic pump, combining precise control with high load capacity and long-term durability. The system’s core components include:

a) Hydraulic Pump (ALBERT)

The ALBERT hydraulic pump converts mechanical energy into hydraulic pressure, supplying power to the entire system. Key features and components include:

Pump body: Houses internal rotating parts and withstands high pressure

Rotating elements (piston, gear, or vane): Convert mechanical motion into hydraulic flow

Gear pumps: Simple and cost-effective for medium/low-pressure applications

Piston pumps: High efficiency, suitable for high pressure and large flow rates

Vane pumps: Provide smooth flow with low noise

Bearings and seals: Ensure smooth rotation and prevent leakage

Inlet and outlet ports: Connect to hydraulic circuits for fluid input and output

The pump's performance directly determines the maximum force applied by the hydraulic cylinders and the system's overall production capacity.

b) Directional Valves and Proportional Control Valves (YUKEN)

Directional valves control the flow path of hydraulic fluid to different parts of the machine, enabling precise cylinder movement. At Hawen Machinery, our YUKEN valves include proportional directional valves, which combine directional control with advanced proportional regulation.

A proportional valve is not a separate valve category, but a control method that continuously and proportionally adjusts hydraulic flow or pressure based on an electrical signal. Operators can set and fine-tune pressure and flow parameters directly via the touchscreen interface, enabling precise control of cylinder speed and compaction force for different block types, sizes, and densities.

Key components include:

Valve body: Encases the internal spool and withstands hydraulic pressure

Spool / actuator: Directs fluid to the correct cylinder at the appropriate time

Seals and O-rings: Prevent leakage and maintain system pressure stability

Ports and passages: Connect hydraulic circuits for supply, return, and control flow

This configuration ensures smooth, responsive, and highly repeatable motion, combining the functional reliability of directional control with the flexibility and accuracy of proportional control.

The pump's performance directly determines the maximum force applied by the hydraulic cylinders and the system's overall production capacity.

b) Directional Valves and Proportional Control Valves (YUKEN)

Directional valves control the flow path of hydraulic fluid to different parts of the machine, enabling precise cylinder movement. At Hawen Machinery, our YUKEN valves include proportional directional valves, which combine directional control with advanced proportional regulation.

A proportional valve is not a separate valve category, but a control method that continuously and proportionally adjusts hydraulic flow or pressure based on an electrical signal. Operators can set and fine-tune pressure and flow parameters directly via the touchscreen interface, enabling precise control of cylinder speed and compaction force for different block types, sizes, and densities.

Key components include:

Valve body: Encases the internal spool and withstands hydraulic pressure

Spool / actuator: Directs fluid to the correct cylinder at the appropriate time

Seals and O-rings: Prevent leakage and maintain system pressure stability

Ports and passages: Connect hydraulic circuits for supply, return, and control flow

This configuration ensures smooth, responsive, and highly repeatable motion, combining the functional reliability of directional control with the flexibility and accuracy of proportional control.

c) Industrial Oil Cooler

To maintain optimal operating temperature, Hawen Machinery integrates an industrial oil cooler into the hydraulic system. During continuous production, hydraulic oil temperature naturally rises due to pressure, flow resistance, and energy conversion losses.

The industrial oil cooler performs the following critical functions:

Dissipates excess heat from hydraulic oil

Maintains stable oil viscosity, ensuring consistent system response

Prevents premature aging of seals, hoses, and oil

Improves system efficiency and reliability during long operating hours

By keeping hydraulic oil within the optimal temperature range, the oil cooler significantly extends component lifespan and ensures stable performance even under high-load, high-output production conditions.

d) Filters and Sensors

Filters: Remove contaminants from hydraulic oil, protecting pumps, valves, and cylinders

Sensors: Monitor pressure, temperature, and oil level, preventing system failure and ensuring safe operation

3. How Hydraulic Systems Form Blocks

Block production relies on precise hydraulic coordination:

Concrete or mixed material is loaded into the mold

Hydraulic cylinders apply controlled pressure, compacting the mixture and eliminating air voids

The hydraulic system lifts and transfers the pallet, allowing smooth block discharge

Both pressure and speed are adjustable to suit hollow blocks, solid blocks, pavers, and curbstones

This precise balance of force and speed enables high-efficiency production with minimal material waste.

4. Advantages Over Mechanical Systems

Compared with purely mechanical systems, hydraulic systems—especially those using YUKEN valves and ALBERT pumps—offer significant advantages:

Consistent quality: Repeatable pressure and motion control

Reduced maintenance: Fewer mechanical wear points

High flexibility: Easy adaptation to different block products

Energy efficiency: Proportional control optimizes power usage

Enhanced safety: Controlled motion and overload protection

c) Industrial Oil Cooler

To maintain optimal operating temperature, Hawen Machinery integrates an industrial oil cooler into the hydraulic system. During continuous production, hydraulic oil temperature naturally rises due to pressure, flow resistance, and energy conversion losses.

The industrial oil cooler performs the following critical functions:

Dissipates excess heat from hydraulic oil

Maintains stable oil viscosity, ensuring consistent system response

Prevents premature aging of seals, hoses, and oil

Improves system efficiency and reliability during long operating hours

By keeping hydraulic oil within the optimal temperature range, the oil cooler significantly extends component lifespan and ensures stable performance even under high-load, high-output production conditions.

d) Filters and Sensors

Filters: Remove contaminants from hydraulic oil, protecting pumps, valves, and cylinders

Sensors: Monitor pressure, temperature, and oil level, preventing system failure and ensuring safe operation

3. How Hydraulic Systems Form Blocks

Block production relies on precise hydraulic coordination:

Concrete or mixed material is loaded into the mold

Hydraulic cylinders apply controlled pressure, compacting the mixture and eliminating air voids

The hydraulic system lifts and transfers the pallet, allowing smooth block discharge

Both pressure and speed are adjustable to suit hollow blocks, solid blocks, pavers, and curbstones

This precise balance of force and speed enables high-efficiency production with minimal material waste.

4. Advantages Over Mechanical Systems

Compared with purely mechanical systems, hydraulic systems—especially those using YUKEN valves and ALBERT pumps—offer significant advantages:

Consistent quality: Repeatable pressure and motion control

Reduced maintenance: Fewer mechanical wear points

High flexibility: Easy adaptation to different block products

Energy efficiency: Proportional control optimizes power usage

Enhanced safety: Controlled motion and overload protection

5. Maintenance Best Practices

To ensure long-term performance and reliability:

Regularly check hydraulic oil levels and temperature

Replace filters according to maintenance schedules

Inspect hoses, seals, and fittings for leaks

Monitor pressure and temperature sensor readings

Perform preventive maintenance on pumps, valves, cylinders, and oil coolers

Proper maintenance ensures continuous, stable, and high-quality block production.

Conclusion

At Hawen Machinery, our hydraulic stations integrate Japanese YUKEN proportional and directional valves, American ALBERT hydraulic pumps, and industrial oil cooling systems to deliver precision, power, and durability. Advanced hydraulic systems are the core of our block machines, enabling efficient, stable, and high-quality block production while minimizing energy consumption, wear, and labor dependency. Understanding the components and operating principles of hydraulic systems clearly demonstrates why they are indispensable in modern block manufacturing.

5. Maintenance Best Practices

To ensure long-term performance and reliability:

Regularly check hydraulic oil levels and temperature

Replace filters according to maintenance schedules

Inspect hoses, seals, and fittings for leaks

Monitor pressure and temperature sensor readings

Perform preventive maintenance on pumps, valves, cylinders, and oil coolers

Proper maintenance ensures continuous, stable, and high-quality block production.

Conclusion

At Hawen Machinery, our hydraulic stations integrate Japanese YUKEN proportional and directional valves, American ALBERT hydraulic pumps, and industrial oil cooling systems to deliver precision, power, and durability. Advanced hydraulic systems are the core of our block machines, enabling efficient, stable, and high-quality block production while minimizing energy consumption, wear, and labor dependency. Understanding the components and operating principles of hydraulic systems clearly demonstrates why they are indispensable in modern block manufacturing.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China