Why choose GMT Pallet for block factory production?

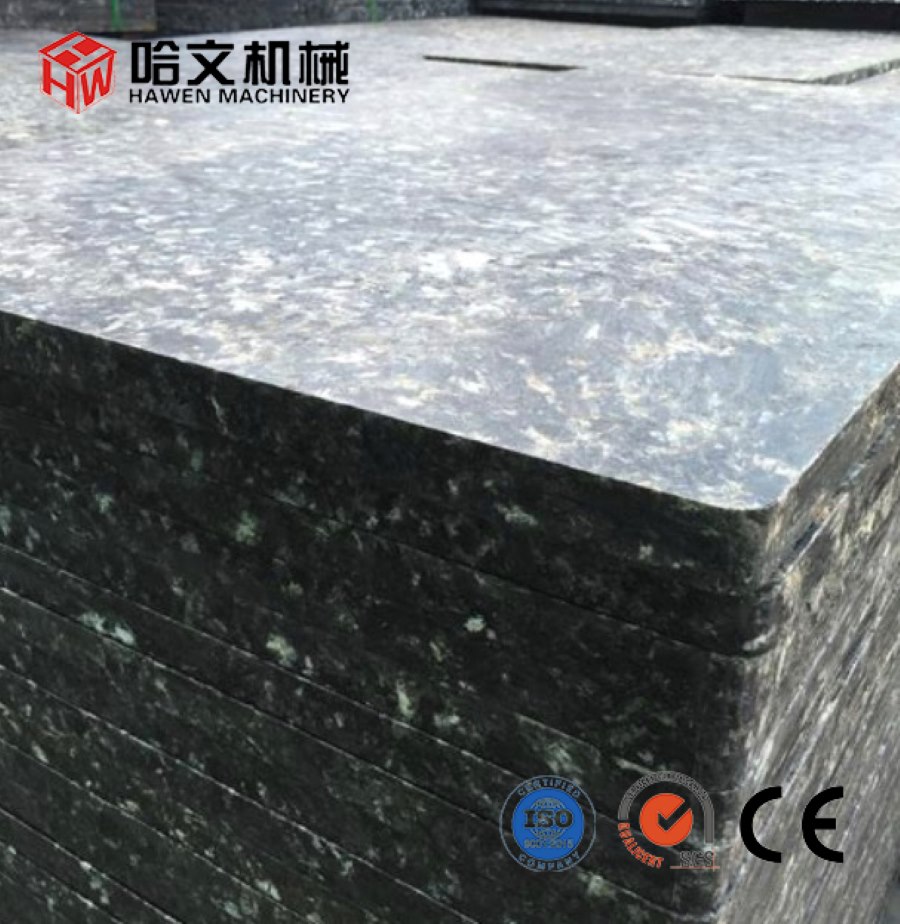

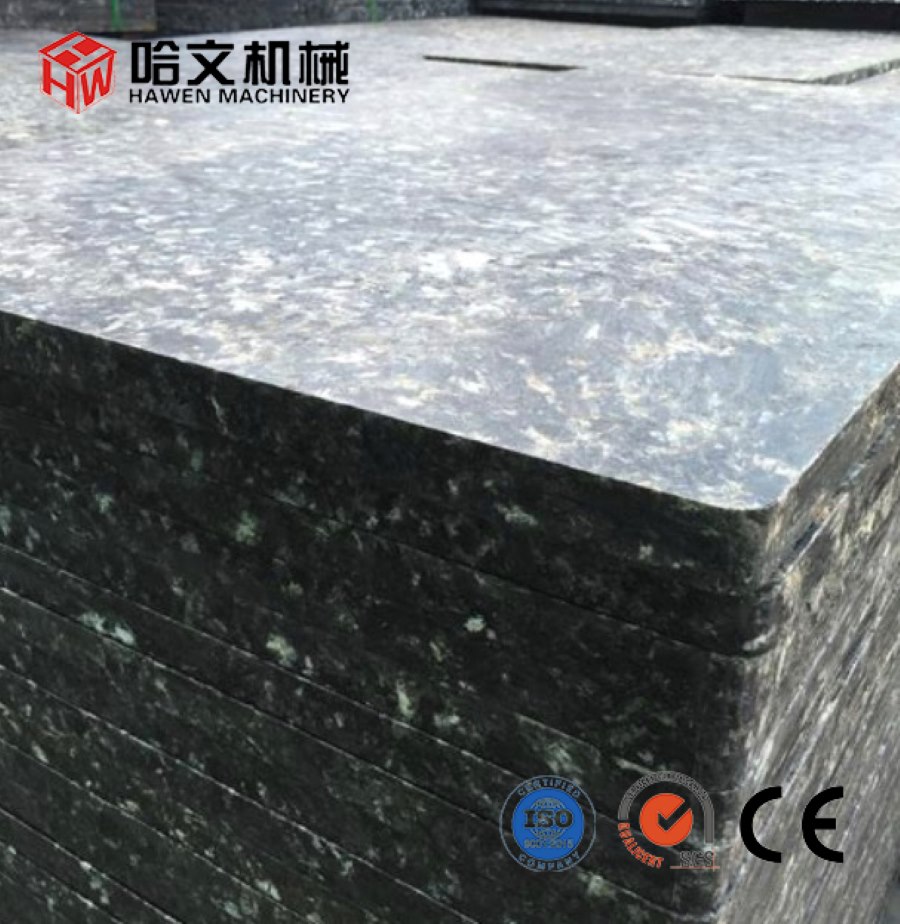

GMT Pallet,the full name is Glass Mat Reinforced Thermoplastics,it is a kind of plastic brick pallets, which is made of fiber glass as reinforcing material and thermoplastic resin composite material, through heating and pressurizing.The glass fiber is three-dimensionally staggered like steel, and the resin is coated with glass fiber like cement-coated steel.

The GMT raw material is a new type of engineering plastic, which was developed in the past few years.

It can be recycled, so it is considered one of the most promising new green materials.

Now, the materials are widely applied in construction industry (like formwork) and concrete block machine pallets etc,it can be suitable for hollow block,solid block ,interlocking paver production,helping getting high quality of concrete product.

1.Feature of GMT Pallet

1.2 Corrosion and Moisture Resistance

Ideal for harsh environments, GMT pallet features include resistance to humidity, chemicals, and temperature fluctuations, ensuring longevity even in demanding industrial settings.

1.3 Customizable Design for Block Factories

Tailored for block manufacturing workflows, GMT Pallets can be designed with reinforced edges and load-bearing capacities up to 500~600kg, aligning with the heavy-duty requirements of concrete block and curb stone and paving stone production.

2. Advantages of GMT Pallet Over Conventional Alternatives

2.1 Cost Efficiency and Sustainability

The advantage of GMT Pallet lies in its 100% recyclability, reducing waste . Businesses save long-term costs through minimal maintenance and a lifespan exceeding 10 years.

2.2 Hygiene and Compliance

Unlike wooden pallets, GMT Pallets eliminate risks of splinters, pests, or fungal growth, meeting stringent international hygiene standards—a critical factor for export-oriented industries.

2.3 Reduced Carbon Footprint

The lightweight design lowers fuel consumption during transportation, supporting eco-friendly supply chains while maintaining load integrity.

3. Benefits of using GMT Pallets for block factories

3.1 Optimized Workflow in Concrete Block Production

The GMT Pallet for Block Factory streamlines material handling with smooth surfaces that prevent block abrasion and ensure consistent product quality. Its compatibility with automated systems reduces manual labor by 40%.

3.2 Safe Storage and Stacking

With uniform dimensions and anti-slip surfaces, GMT Pallets enable secure stacking of blocks, minimizing workplace accidents and maximizing warehouse space utilization.

3.3 Reduced Maintenance Costs

GMT Pallets require no repairs or treatments (unlike wooden pallets), cutting long-term operational expenses. Their 10+ year lifespan outperforms traditional alternatives.

3.4 Adaptability to Harsh Environments

GMT Pallet Features like resistance to extreme temperatures (from -20°C to70°C) and humidity make them ideal for Saudi Arabia’s climate, ensuring reliable performance in outdoor block storage or high-heat curing processes.

Hawen machinery provide customized GMT Pallet according to the dimension required for your block making machine.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China