Why Are Block Machines Essential in Modern Construction?

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-01-10

Why Are Block Machines Essential in Modern Construction?

In today's fast-evolving construction industry, efficiency, consistency, and sustainability are more important than ever. As urbanization accelerates and infrastructure projects grow in scale, block making machines have become an essential part of modern construction, replacing traditional, labor-intensive methods.

1. Meeting the Demand for Fast Construction

Modern construction projects operate under tight schedules. Manual brick production cannot meet the required speed or volume. Block machines enable mass production, delivering thousands of uniform blocks per day with minimal downtime.

By automating mixing, molding, and vibration, block machines significantly reduce construction timelines, helping contractors complete projects on time and within budget.

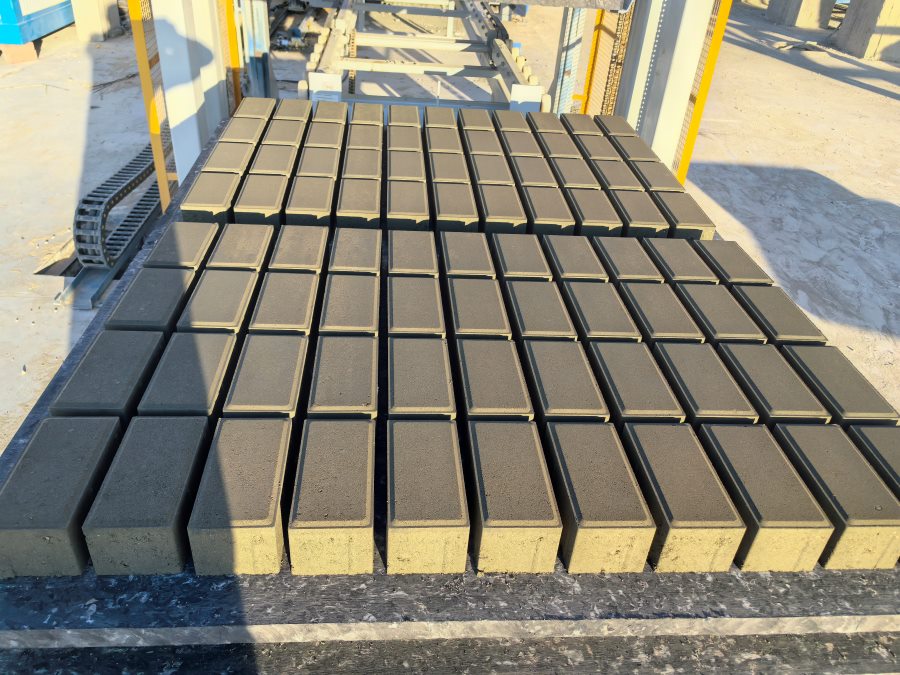

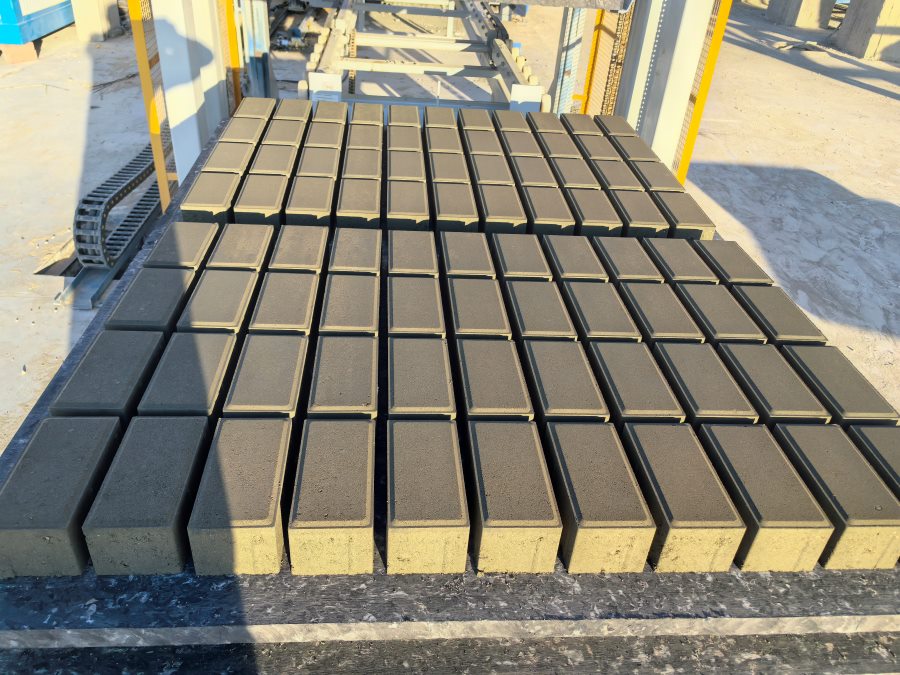

2. Consistent Quality and Strength

One of the biggest challenges in traditional brick making is inconsistency. Variations in size, strength, and density often lead to structural issues.

Block making machines ensure:

Uniform dimensions

Stable compressive strength

Controlled vibration and compaction

2. Consistent Quality and Strength

One of the biggest challenges in traditional brick making is inconsistency. Variations in size, strength, and density often lead to structural issues.

Block making machines ensure:

Uniform dimensions

Stable compressive strength

Controlled vibration and compaction

This consistency improves structural safety and reduces material waste during construction.

3. Cost Efficiency and Labor Optimization

Rising labor costs and workforce shortages have made automation a necessity. Block machines:

Reduce dependence on manual labor

Lower long-term production costs

Improve productivity per worker

With one operator controlling an entire production line, companies can optimize labor allocation while maintaining high output levels.

4. Versatility for Different Construction Needs

Modern block machines are designed to be multifunctional. By simply changing the mould, the same machine can produce:

Hollow blocks

This consistency improves structural safety and reduces material waste during construction.

3. Cost Efficiency and Labor Optimization

Rising labor costs and workforce shortages have made automation a necessity. Block machines:

Reduce dependence on manual labor

Lower long-term production costs

Improve productivity per worker

With one operator controlling an entire production line, companies can optimize labor allocation while maintaining high output levels.

4. Versatility for Different Construction Needs

Modern block machines are designed to be multifunctional. By simply changing the mould, the same machine can produce:

Hollow blocks

Solid blocks

Paving stones

Curbstones

This flexibility allows manufacturers to respond quickly to market demand without investing in multiple machines.

5. Supporting Sustainable Construction

Sustainability is now a core requirement in construction projects worldwide. Block machines contribute by:

Using industrial by-products such as fly ash

Reducing material waste

Producing energy-efficient building blocks

Eco-friendly block production supports green building standards while lowering raw material costs.

6. Compatibility with Modern Production Systems

Block machines integrate seamlessly with:

Cement silos

Concrete batching plants

Automatic pallet and stacking systems

This integration enables continuous, automated production lines, improving operational efficiency and production stability.

7. Long-Term Investment Value

Although block machines require an initial investment, their long service life, low maintenance cost, and high output make them a smart long-term solution. For contractors and manufacturers, they provide a reliable foundation for scalable business growth.

Conclusion

Block making machines are no longer optional equipment in modern construction — they are essential infrastructure tools. By delivering speed, consistency, versatility, and sustainability, block machines help construction companies meet today’s challenges and prepare for tomorrow’s growth.

For any business involved in housing, infrastructure, or precast concrete production, investing in the right block machine is a strategic decision for long-term success.

7. Long-Term Investment Value

Although block machines require an initial investment, their long service life, low maintenance cost, and high output make them a smart long-term solution. For contractors and manufacturers, they provide a reliable foundation for scalable business growth.

Conclusion

Block making machines are no longer optional equipment in modern construction — they are essential infrastructure tools. By delivering speed, consistency, versatility, and sustainability, block machines help construction companies meet today’s challenges and prepare for tomorrow’s growth.

For any business involved in housing, infrastructure, or precast concrete production, investing in the right block machine is a strategic decision for long-term success.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China