What Is a Block Machine and How Does It Work

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-01-08

What Is a Block Machine and How Does It Work

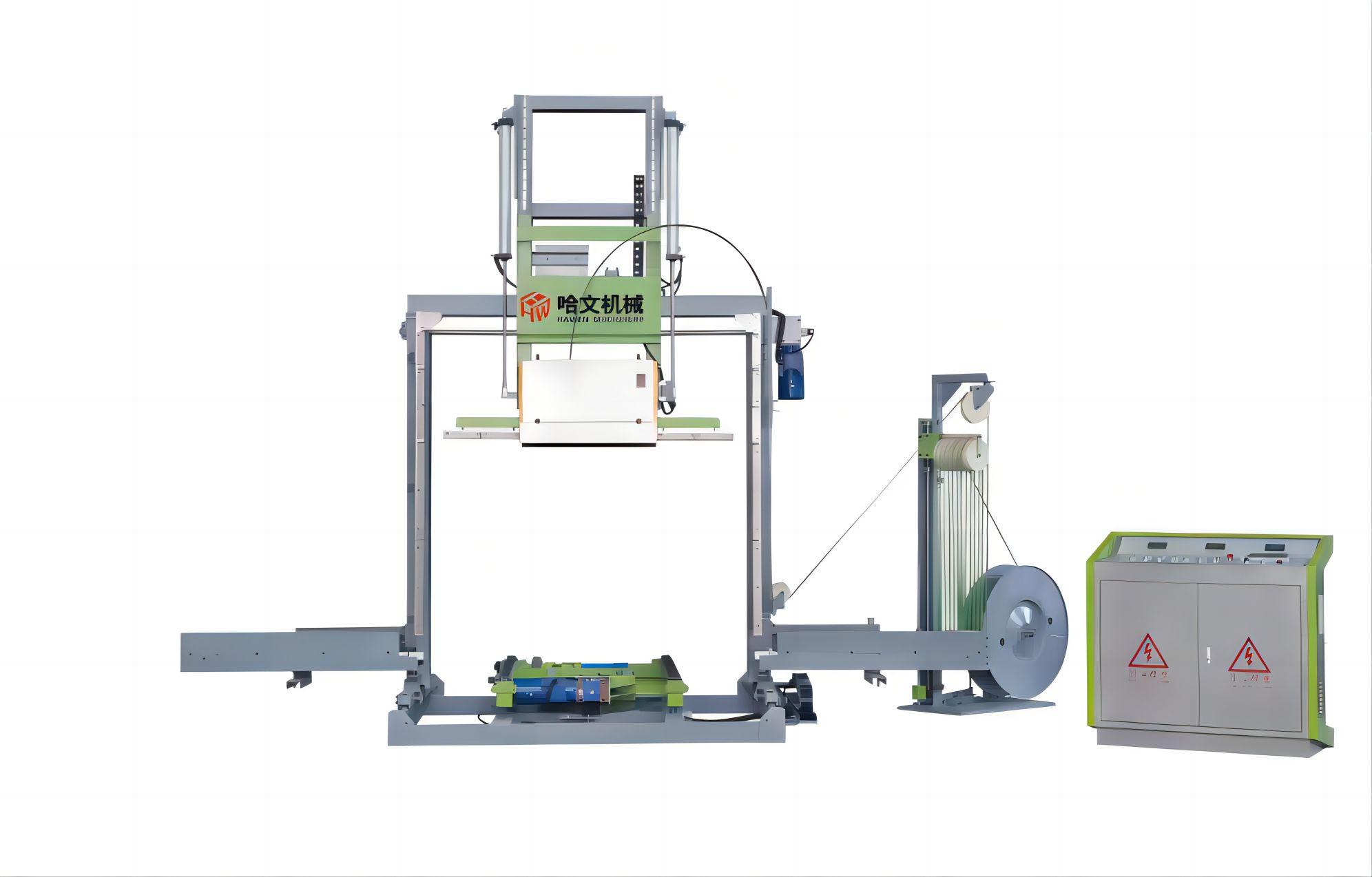

In the construction industry, efficiency, precision, and versatility are key to staying ahead. One of the most essential pieces of equipment in modern construction is a block machine. At Hawen Machinery, we specialize in manufacturing high-quality block making machines designed to meet the diverse needs of construction projects worldwide. But what exactly is a block machine, and how does it work? Let’s dive in.

What Is a Block Machine?

A block machine, also known as a concrete block making machine, is a specialized piece of equipment used to manufacture concrete blocks, bricks, pavers, and other similar construction materials. These machines are widely used in building projects, road construction, landscaping, and industrial applications. The main purpose of a block machine is to automate the production process, ensuring uniform quality, precise dimensions, and high output.

At Hawen Machinery, our machines are designed to be multifunctional, capable of producing hollow blocks, solid bricks, paving stones, and curb stones simply by changing molds. This versatility makes our machines a preferred choice for both small-scale workshops and large-scale industrial plants.

How Does a Block Machine Work?

What Is a Block Machine?

A block machine, also known as a concrete block making machine, is a specialized piece of equipment used to manufacture concrete blocks, bricks, pavers, and other similar construction materials. These machines are widely used in building projects, road construction, landscaping, and industrial applications. The main purpose of a block machine is to automate the production process, ensuring uniform quality, precise dimensions, and high output.

At Hawen Machinery, our machines are designed to be multifunctional, capable of producing hollow blocks, solid bricks, paving stones, and curb stones simply by changing molds. This versatility makes our machines a preferred choice for both small-scale workshops and large-scale industrial plants.

How Does a Block Machine Work?

A block machine operates through a combination of mixing, molding, and compacting concrete materials. Here’s a simplified breakdown of the process:

Material Preparation:

Raw materials such as cement, sand, aggregates, and water are measured and mixed in precise proportions. Some advanced Hawen machines include automated batching systems for consistent quality.

Molding:

The mixed concrete is fed into molds. Hawen block machines offer various mold sizes and shapes, allowing for the creation of customized blocks, pavers, or bricks.

Compacting and Vibrating:

The concrete mixture is then compacted using vibration and hydraulic pressure. This ensures that each block is dense, durable, and uniform in shape.

A block machine operates through a combination of mixing, molding, and compacting concrete materials. Here’s a simplified breakdown of the process:

Material Preparation:

Raw materials such as cement, sand, aggregates, and water are measured and mixed in precise proportions. Some advanced Hawen machines include automated batching systems for consistent quality.

Molding:

The mixed concrete is fed into molds. Hawen block machines offer various mold sizes and shapes, allowing for the creation of customized blocks, pavers, or bricks.

Compacting and Vibrating:

The concrete mixture is then compacted using vibration and hydraulic pressure. This ensures that each block is dense, durable, and uniform in shape.

Curing:

Once molded, the blocks are carefully cured to achieve maximum strength. Depending on the type of block, curing can be done naturally or using steam-cured methods.

Output and Packaging:

Finished blocks are ready for immediate use or can be packed for storage and transportation. Hawen machinery often integrates automatic stacking and palletizing systems for efficiency and minimal labor.

Why Choose Hawen Block Machines?

Choosing the right block machine can make a significant difference in your production efficiency and profitability. Here’s why Hawen Machinery stands out:

High Productivity: Our machines produce blocks quickly and consistently, helping you meet tight deadlines.

Versatility: One machine can create a wide range of products simply by changing molds.

Durable Design: Built with high-quality materials and robust construction, our machines offer long-term reliability.

User-Friendly Operation: Easy to operate and maintain, even for first-time users.

Comprehensive Support: Hawen provides full technical guidance, from installation to troubleshooting, ensuring smooth operation.

Curing:

Once molded, the blocks are carefully cured to achieve maximum strength. Depending on the type of block, curing can be done naturally or using steam-cured methods.

Output and Packaging:

Finished blocks are ready for immediate use or can be packed for storage and transportation. Hawen machinery often integrates automatic stacking and palletizing systems for efficiency and minimal labor.

Why Choose Hawen Block Machines?

Choosing the right block machine can make a significant difference in your production efficiency and profitability. Here’s why Hawen Machinery stands out:

High Productivity: Our machines produce blocks quickly and consistently, helping you meet tight deadlines.

Versatility: One machine can create a wide range of products simply by changing molds.

Durable Design: Built with high-quality materials and robust construction, our machines offer long-term reliability.

User-Friendly Operation: Easy to operate and maintain, even for first-time users.

Comprehensive Support: Hawen provides full technical guidance, from installation to troubleshooting, ensuring smooth operation.

Conclusion

A block machine is more than just a piece of equipment—it’s a reliable partner in construction. With Hawen Machinery, you gain access to innovative technology, high-quality production, and unmatched support. Whether you are starting a small brick-making workshop or running a large-scale block production plant, Hawen block machines help you maximize efficiency and profitability.

Conclusion

A block machine is more than just a piece of equipment—it’s a reliable partner in construction. With Hawen Machinery, you gain access to innovative technology, high-quality production, and unmatched support. Whether you are starting a small brick-making workshop or running a large-scale block production plant, Hawen block machines help you maximize efficiency and profitability.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China