QT10 Plus Automatic Paver and Curb Stone Production Line in Russia

The Hawen QT10-15 Plus automatic block production line is now fully operational in Orenburg Russia, showcasing Hawen’s cutting-edge technology for manufacturing a wide variety of concrete products.

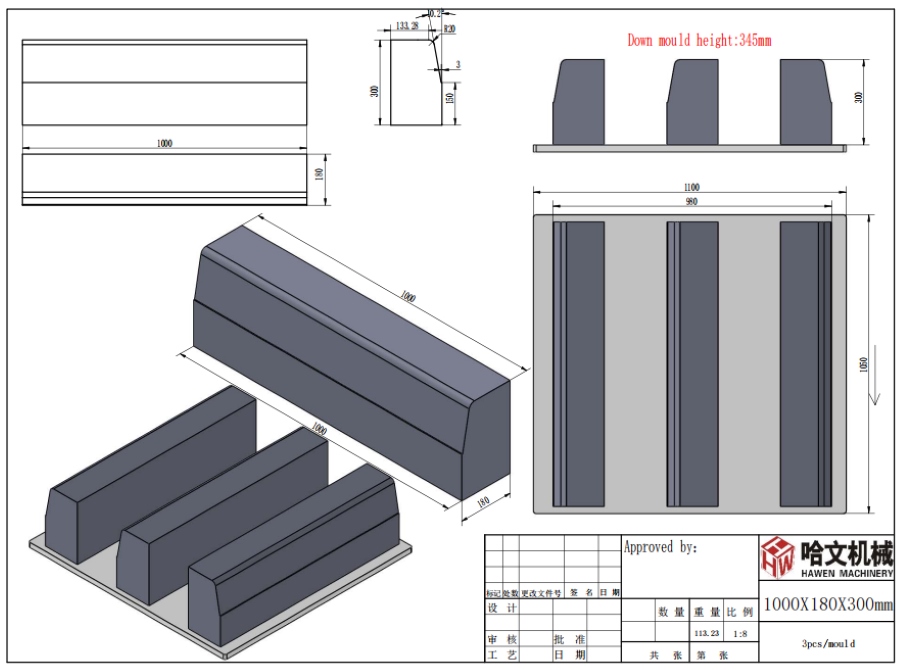

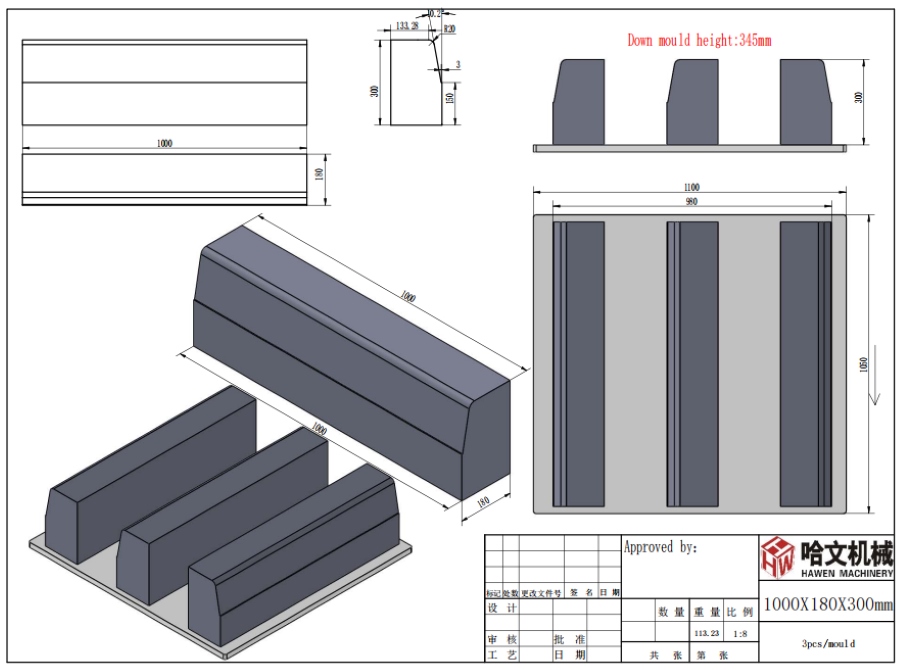

This advanced line produces hollow blocks, high-strength interlocking pavers, and large-format curb stones up to 1000mm in length and 300mm in height.

Equipped with a planetary mixer, steam curing system, and a fully automatic cuber, it ensures high productivity, excellent product quality, and minimal labor intervention.

Advantages of Hawen QT10-15 Plus Block Machine

✅ Maximum Product Height of 400mm

With the pallet size at 1100x1100mm,Capable of producing oversized concrete elements, including large curb stones and custom architectural blocks,the height of curb stone reach 300mm.

✅ Versatility in Product Range

Designed for hollow blocks, solid bricks, decorative interlocking pavers, and large curb stones.

✅ High Efficiency & Automation

Siemens PLC control, automatic cuber system, and intelligent operation workflow minimize manual handling and enhance production speed.

✅ Superior Product Quality

Advanced vibration and hydraulic systems deliver high compaction density and smooth surface finishes.

Design Features of Hawen QT10-15 Plus block making machine

✅Robust Steel Frame Construction: Engineered for continuous, heavy-duty production.

✅High-Efficiency Vibration System: Ensures uniform density and eliminates air pockets in all products.

✅Planetary Mixer: Provides superior mixing homogeneity, critical for color consistency and strength in pavers and curb stones.

✅Automatic Cuber System: Simplifies stacking and handling, saving time and labor costs.

✅Steam Curing Integration: Accelerates the curing process and improves the strength and durability of concrete products in colder climates.

Multifunction Hawen Mixing System Design: Dual Application for Ready-Mix and Block Production

The Hawen multifunction mixing system is an innovative design that delivers maximum flexibility and efficiency for concrete production.

This advanced system is engineered to serve dual applications:

✅ Ready-Mix Batching Plant: It provides high-performance mixing for ready-mix concrete, ensuring a consistent and homogeneous mix suitable for large-scale construction projects.

✅ Concrete Block Production: It also seamlessly integrates into block making lines, using a transit material hopper,supplying precise, high-quality concrete mix essential for manufacturing hollow blocks, pavers, curb stones, and other precast products.

How to Make Quality Interlocking Paver

✅ Premium Concrete Mix: Achieved with Hawen’s planetary mixer for uniform blending of aggregates, cement, water, and color pigments.

✅ Precision Moulds: High-quality moulds ensure sharp edges and consistent shapes.

✅ Powerful Compaction: Advanced vibration technology eliminates air voids for maximum durability.

✅ Steam Curing System: Enables rapid curing, especially useful for colored pavers, ensuring vibrant colors and enhanced surface strength.

✅ Automated Handling: The automatic cuber ensures safe stacking and minimizes damage during handling.

Hawen Machinery continues its strong presence in Russia, delivering high-performance block production solutions that help manufacturers meet growing demands for premium-quality concrete products in the construction industry.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China