How Block Machines Support Sustainable Construction Practices

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-02-11

How Block Machines Support Sustainable Construction Practices

As the global construction industry confronts mounting pressure from climate commitments, resource constraints, and rising material costs, sustainability has shifted from a rhetorical ambition to an operational imperative. In this context, block machines—often perceived as purely industrial equipment—are emerging as strategic enablers of sustainable construction. Through material efficiency, energy optimization, lifecycle durability, and intelligent automation, modern block-making technology reshapes how concrete products are manufactured, deployed, and evaluated across their entire value chain.

1. Material Efficiency: Doing More with Less

At the core of sustainable construction lies a simple but demanding principle: maximize output while minimizing resource input. Advanced block machines support this goal by enabling precise control over mix design, compaction, and forming accuracy. Through optimized vibration and compaction mechanisms, raw materials such as cement, aggregates, and additives are utilized more efficiently, reducing overdesign and unnecessary material redundancy.

Well-engineered block machines can consistently achieve high-density blocks with lower cement ratios, without compromising compressive strength or dimensional stability. This reduction in cement consumption is particularly significant, given that cement production alone accounts for a substantial share of global CO₂ emissions. In this sense, every marginal improvement in block-making efficiency translates directly into measurable environmental gains.

2. Energy Optimization Through Intelligent Power Systems

Sustainable manufacturing is inseparable from energy performance. Modern block machines increasingly rely on refined hydraulic architectures that balance responsiveness, load-bearing capacity, and long-term reliability. At Hawen Machinery, for instance, the hydraulic systems are configured around premium international components—such as precision-engineered proportional and directional valves from Japan and high-performance hydraulic pumps from the United States—ensuring stable pressure control under continuous operation.

This refined hydraulic coordination minimizes energy loss caused by pressure fluctuation or inefficient flow paths. Over extended production cycles, such optimization significantly lowers electricity consumption per unit of output, aligning industrial productivity with environmental responsibility rather than placing the two in opposition.

3. Advanced Vibration Technology and Resource Conservation

Vibration is not merely a mechanical function; it is a decisive factor in both block quality and sustainability performance. Hawen Machinery applies a four-shaft vibration box configuration in which eccentric weights are arranged externally rather than enclosed within the housing. This structural choice reduces internal resistance during vibration transmission, allowing compaction energy to act directly on the concrete mixture.

The result is a more uniform internal structure, improved surface finish, and—critically—a reduced reliance on high cement content to achieve strength targets. By improving compaction efficiency, the vibration system indirectly contributes to material conservation while simultaneously enhancing production efficiency and product consistency.

2. Energy Optimization Through Intelligent Power Systems

Sustainable manufacturing is inseparable from energy performance. Modern block machines increasingly rely on refined hydraulic architectures that balance responsiveness, load-bearing capacity, and long-term reliability. At Hawen Machinery, for instance, the hydraulic systems are configured around premium international components—such as precision-engineered proportional and directional valves from Japan and high-performance hydraulic pumps from the United States—ensuring stable pressure control under continuous operation.

This refined hydraulic coordination minimizes energy loss caused by pressure fluctuation or inefficient flow paths. Over extended production cycles, such optimization significantly lowers electricity consumption per unit of output, aligning industrial productivity with environmental responsibility rather than placing the two in opposition.

3. Advanced Vibration Technology and Resource Conservation

Vibration is not merely a mechanical function; it is a decisive factor in both block quality and sustainability performance. Hawen Machinery applies a four-shaft vibration box configuration in which eccentric weights are arranged externally rather than enclosed within the housing. This structural choice reduces internal resistance during vibration transmission, allowing compaction energy to act directly on the concrete mixture.

The result is a more uniform internal structure, improved surface finish, and—critically—a reduced reliance on high cement content to achieve strength targets. By improving compaction efficiency, the vibration system indirectly contributes to material conservation while simultaneously enhancing production efficiency and product consistency.

4. Automation and Digital Control: Reducing Waste at the Source

Human error, parameter drift, and inconsistent operation are often overlooked sources of waste in traditional block production. Intelligent control systems mitigate these risks by embedding consistency into every production cycle. Hawen Machinery incorporates a programmable logic control platform from SIEMENS, paired with a user-friendly touch interface and remote connectivity functions.

This digital ecosystem enables real-time monitoring of machine status, vibration parameters, cycle times, and fault diagnostics. More importantly, it allows technical teams to adjust operating parameters remotely, ensuring that machines remain within optimal efficiency windows regardless of operator experience or environmental variation. By stabilizing production quality at scale, digital control systems prevent defective blocks, rework, and material loss before they occur.

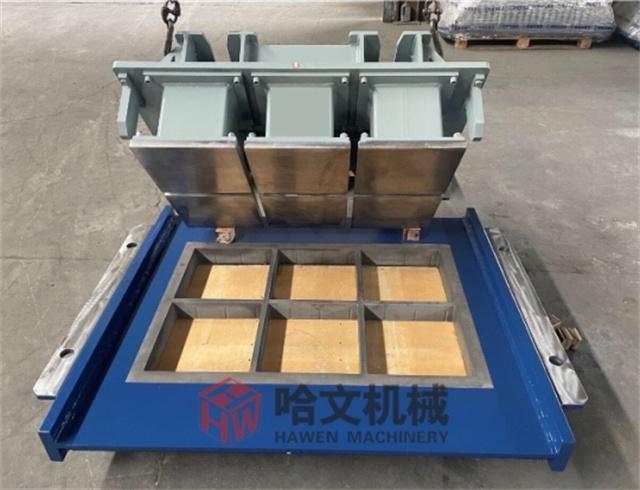

5. Mold Engineering and Cross-Platform Compatibility

Sustainability also depends on longevity and adaptability. Mold systems that wear prematurely or lack compatibility across platforms impose hidden environmental costs through frequent replacement and redundant manufacturing. Hawen Machinery addresses this issue by designing molds in accordance with original specifications used by leading global brands, including MASA, HESS, ZENITH, POYATOS, BESSER, TIGER, and others.

Such cross-brand compatibility allows manufacturers to integrate Hawen molds into existing production lines without structural modification. Precision machining, optimized heat treatment, and rational material selection ensure smooth demolding, dimensional accuracy, and extended service life. From a sustainability perspective, longer mold lifecycles reduce steel consumption, machining energy, and downtime-related inefficiencies.

6. Supporting Circular Construction Models

Block machines play a pivotal role in enabling circular construction practices, particularly through the use of recycled aggregates, industrial by-products, and alternative raw materials. Modern machines are engineered to accommodate variable material characteristics while maintaining stable output quality. This flexibility allows manufacturers to incorporate recycled concrete, fly ash, or slag into their mix designs, diverting waste from landfills and lowering embodied carbon.

By transforming local waste streams into standardized construction products, block machines contribute to regional self-sufficiency and reduce transportation-related emissions—a benefit often underestimated in sustainability assessments.

7. Hawen Machinery: Engineering Sustainability into Productivity

Sustainability cannot be retrofitted; it must be engineered from the outset. Hawen Machinery approaches block machine design with a systems-level perspective, integrating mechanical robustness, intelligent control, and energy-conscious components into a coherent whole. Rather than treating sustainability as a marketing add-on, Hawen embeds it into the operational DNA of each production line.

From hydraulic responsiveness and vibration efficiency to digital oversight and mold interoperability, each subsystem is calibrated to support long-term, stable, and resource-efficient production. This philosophy ensures that sustainability does not come at the expense of output, reliability, or commercial viability.

4. Automation and Digital Control: Reducing Waste at the Source

Human error, parameter drift, and inconsistent operation are often overlooked sources of waste in traditional block production. Intelligent control systems mitigate these risks by embedding consistency into every production cycle. Hawen Machinery incorporates a programmable logic control platform from SIEMENS, paired with a user-friendly touch interface and remote connectivity functions.

This digital ecosystem enables real-time monitoring of machine status, vibration parameters, cycle times, and fault diagnostics. More importantly, it allows technical teams to adjust operating parameters remotely, ensuring that machines remain within optimal efficiency windows regardless of operator experience or environmental variation. By stabilizing production quality at scale, digital control systems prevent defective blocks, rework, and material loss before they occur.

5. Mold Engineering and Cross-Platform Compatibility

Sustainability also depends on longevity and adaptability. Mold systems that wear prematurely or lack compatibility across platforms impose hidden environmental costs through frequent replacement and redundant manufacturing. Hawen Machinery addresses this issue by designing molds in accordance with original specifications used by leading global brands, including MASA, HESS, ZENITH, POYATOS, BESSER, TIGER, and others.

Such cross-brand compatibility allows manufacturers to integrate Hawen molds into existing production lines without structural modification. Precision machining, optimized heat treatment, and rational material selection ensure smooth demolding, dimensional accuracy, and extended service life. From a sustainability perspective, longer mold lifecycles reduce steel consumption, machining energy, and downtime-related inefficiencies.

6. Supporting Circular Construction Models

Block machines play a pivotal role in enabling circular construction practices, particularly through the use of recycled aggregates, industrial by-products, and alternative raw materials. Modern machines are engineered to accommodate variable material characteristics while maintaining stable output quality. This flexibility allows manufacturers to incorporate recycled concrete, fly ash, or slag into their mix designs, diverting waste from landfills and lowering embodied carbon.

By transforming local waste streams into standardized construction products, block machines contribute to regional self-sufficiency and reduce transportation-related emissions—a benefit often underestimated in sustainability assessments.

7. Hawen Machinery: Engineering Sustainability into Productivity

Sustainability cannot be retrofitted; it must be engineered from the outset. Hawen Machinery approaches block machine design with a systems-level perspective, integrating mechanical robustness, intelligent control, and energy-conscious components into a coherent whole. Rather than treating sustainability as a marketing add-on, Hawen embeds it into the operational DNA of each production line.

From hydraulic responsiveness and vibration efficiency to digital oversight and mold interoperability, each subsystem is calibrated to support long-term, stable, and resource-efficient production. This philosophy ensures that sustainability does not come at the expense of output, reliability, or commercial viability.

Conclusion: From Equipment to Ethos

In the final analysis, block machines are no longer passive tools in the construction ecosystem. They are active agents shaping how resources are consumed, how emissions are managed, and how quality is standardized at scale. When intelligently designed and responsibly deployed, block machines reconcile the long-standing tension between industrial growth and environmental stewardship.

Sustainable construction is not achieved through isolated gestures, but through cumulative, technically grounded decisions made at every stage of production. By advancing material efficiency, energy optimization, digital control, and lifecycle durability, modern block machines elevate sustainability from an abstract ideal to a measurable, repeatable practice. In doing so, they help redefine the future of construction—not as an extractive industry, but as a disciplined, regenerative system built to endure.

Conclusion: From Equipment to Ethos

In the final analysis, block machines are no longer passive tools in the construction ecosystem. They are active agents shaping how resources are consumed, how emissions are managed, and how quality is standardized at scale. When intelligently designed and responsibly deployed, block machines reconcile the long-standing tension between industrial growth and environmental stewardship.

Sustainable construction is not achieved through isolated gestures, but through cumulative, technically grounded decisions made at every stage of production. By advancing material efficiency, energy optimization, digital control, and lifecycle durability, modern block machines elevate sustainability from an abstract ideal to a measurable, repeatable practice. In doing so, they help redefine the future of construction—not as an extractive industry, but as a disciplined, regenerative system built to endure.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China