Why Block Machines Are Widely Used in Infrastructure Projects

Infrastructure development sits at the intersection of scale, durability, and cost discipline. From urban roads and drainage systems to industrial parks and municipal housing, project owners demand construction solutions that are not only structurally reliable but also economically and operationally efficient. Against this backdrop, block machines have become a cornerstone of modern infrastructure projects worldwide—not by coincidence, but by design.

1. Standardization Meets Mass Production

One of the defining characteristics of infrastructure projects is their reliance on standardized components. Concrete blocks, pavers, and curb stones must meet uniform dimensional tolerances and performance benchmarks to ensure interchangeability and long-term serviceability. Block machines excel precisely in this domain.

Through highly repeatable molding and compaction processes, block machines enable large-scale production of standardized units with minimal deviation. This consistency simplifies on-site installation, reduces rework, and aligns seamlessly with the industrialized construction logic increasingly favored in public works. In essence, block machines transform concrete products from bespoke items into scalable industrial outputs.

2. Structural Performance and Lifecycle Reliability

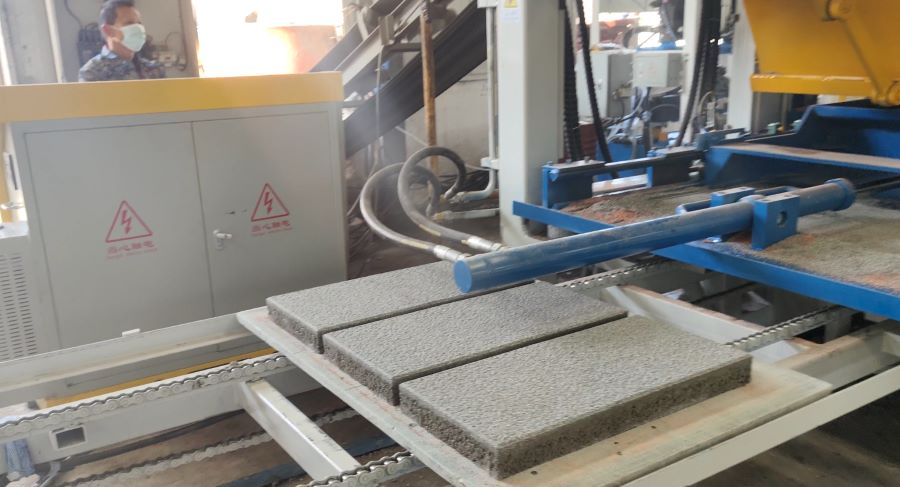

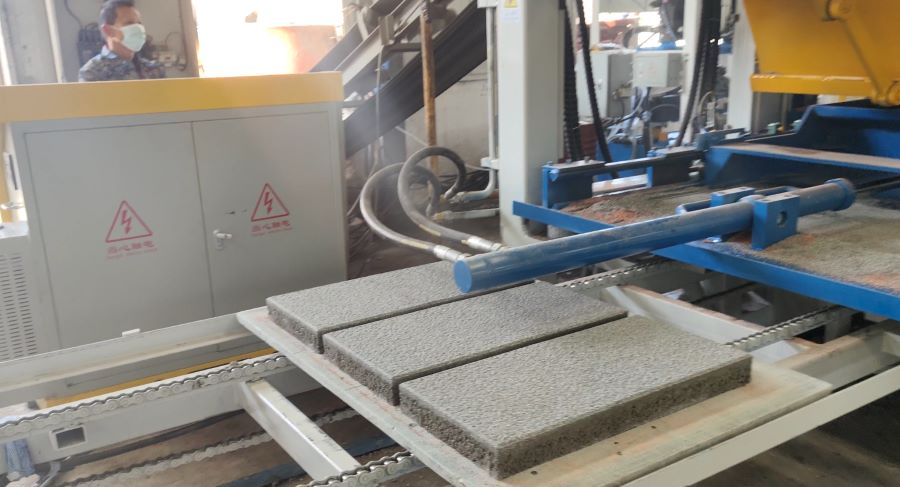

Infrastructure assets are designed for decades, not years. Blocks used in roads, retaining walls, and public utilities must withstand cyclic loading, weathering, and environmental stress. Advanced block machines employ high-pressure compaction combined with optimized vibration systems, ensuring dense internal structure and low porosity.

Such production technology directly translates into higher compressive strength, improved frost resistance, and superior durability. Compared with cast-in-place alternatives, machine-made blocks offer a more predictable performance profile across the entire lifecycle of an infrastructure asset—an attribute highly valued by engineers and public authorities alike.

3. Cost Efficiency Beyond the Surface Level

While initial material costs are always scrutinized, infrastructure decision-makers increasingly focus on total cost of ownership. Block machines contribute to cost efficiency on multiple layers.

First, they allow the use of locally sourced raw materials, reducing transportation dependence. Second, precise batching and compaction minimize cement overconsumption, which is both economically and environmentally significant. Third, high automation reduces labor intensity and mitigates human error. When viewed through an economic lens, block machines offer not merely low unit costs, but structural cost optimization across production, installation, and maintenance phases.

4. Advanced Hydraulic Systems for Industrial Stability

At the heart of any high-performance block machine lies its hydraulic system. In demanding infrastructure applications, stability under continuous load is non-negotiable. High-grade hydraulic architectures—featuring internationally renowned proportional control valves and heavy-duty pumps from leading global manufacturers—ensure smooth pressure regulation, rapid response, and sustained output even under high-frequency operation.

Such systems are engineered to balance precision and robustness, enabling block machines to maintain consistent forming pressure while extending service intervals. This reliability is critical in infrastructure projects where downtime can cascade into significant schedule and cost overruns.

5. Vibration Engineering as a Productivity Multiplier

Vibration technology plays a decisive role in block density and surface quality. Hawen Machinery applies an advanced four-shaft vibration box configuration, with eccentric weights arranged externally rather than enclosed within the housing. This structural choice reduces mechanical resistance during operation and allows vibration energy to be transmitted more directly into the mold cavity.

The result is uniform compaction across the entire block, reduced internal voids, and enhanced material efficiency. Notably, this optimized vibration strategy supports lower cement consumption without compromising strength—an outcome that aligns perfectly with both economic rationality and sustainability objectives in infrastructure construction.

6. Intelligent Control Systems for Predictable Output

Modern infrastructure projects demand not only capacity, but controllability. Hawen Machinery integrates an industrial-grade PLC architecture from SIEMENS, paired with a user-friendly touch interface and remote connectivity. This control ecosystem enables real-time monitoring of machine status, production parameters, and fault diagnostics.

Beyond local operation, remote access allows technical teams to fine-tune settings, analyze performance trends, and support customers proactively. Such digital oversight ensures that block quality remains stable across shifts, sites, and production cycles—an often underestimated yet critical requirement in large-scale infrastructure delivery.

7. Mold Compatibility and Cross-Platform Flexibility

Infrastructure markets are rarely homogeneous. Contractors may operate mixed fleets or expand capacity incrementally. Recognizing this reality, Hawen Machinery engineers molds in accordance with original specifications of leading global block machine brands, including MASA, HESS, ZENITH, POYATOS, BESSER, TIGER, among others.

This cross-platform compatibility ensures accurate alignment, smooth demolding, and consistent block geometry, regardless of the production environment. For infrastructure clients, such flexibility protects prior investments while maintaining uniform product standards—a strategic advantage in long-term project planning.

8. Sustainability and Policy Alignment

As infrastructure policy increasingly emphasizes low-carbon construction and resource efficiency, block machines offer a pragmatic pathway forward. Optimized material usage, reduced waste, and long service life collectively lower the environmental footprint of concrete products. Moreover, the ability to integrate recycled aggregates further strengthens their alignment with circular economy principles now embedded in many public procurement frameworks.

A Broader Perspective: Machinery as Infrastructure Itself

Ultimately, block machines are widely used in infrastructure projects because they embody the same values that infrastructure itself represents: durability, efficiency, scalability, and foresight. They convert raw materials into standardized building units with industrial precision, support economic discipline over long project horizons, and adapt seamlessly to evolving technical and environmental standards.

At Hawen Machinery, we view block machines not merely as production equipment, but as foundational infrastructure behind the infrastructure. When machines are engineered with rigor, intelligence, and global compatibility, they do more than produce blocks—they quietly uphold the reliability of roads we drive on, cities we inhabit, and systems we depend on every day.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China