QT6-15 paver and curb stone making plant successful running in Uzbekistan

Today, we introduce the QT6-15 Paver and Curb Stone Making Plant, a high-performance and fully automatic solution designed for professional concrete product manufacturers.

Developed by HAWEN MACHINERY, the combines robust mechanical design, intelligent control, and flexible production capability, making it an ideal choice for producing pavers, curbstones, hollow blocks, and solid bricks.

Designed for Stable and Continuous Production

The QT6-15 block making machine features a heavy-duty steel frame manufactured with precision welding, ensuring long-term stability under continuous industrial operation.

Equipped with a Japanese YUKEN hydraulic forming system and an optimized vibration platform, the machine delivers high compaction force, consistent block density, and excellent product strength.

Designed for Stable and Continuous Production

The QT6-15 block making machine features a heavy-duty steel frame manufactured with precision welding, ensuring long-term stability under continuous industrial operation.

Equipped with a Japanese YUKEN hydraulic forming system and an optimized vibration platform, the machine delivers high compaction force, consistent block density, and excellent product strength.

Designed for operation in low-temperature environments, the hydraulic system is fitted with an integrated oil heating function, allowing the machine to operate smoothly even when ambient temperatures drop to 0°C or below.

Intelligent Control System

The QT6-15 plant is controlled by a Siemens PLC intelligent control system, offering:

Touch-screen operation

Automatic fault diagnosis

Easy parameter adjustment

Stable and reliable production control

This intelligent system reduces operator dependency while improving production accuracy and consistency.

Accurate Batching and Mixing for Superior Product Quality

The production line is equipped with PL800-II concrete batching machine and a JS500 forced concrete mixer, ensuring uniform material blending and precise mix ratios.

Designed for operation in low-temperature environments, the hydraulic system is fitted with an integrated oil heating function, allowing the machine to operate smoothly even when ambient temperatures drop to 0°C or below.

Intelligent Control System

The QT6-15 plant is controlled by a Siemens PLC intelligent control system, offering:

Touch-screen operation

Automatic fault diagnosis

Easy parameter adjustment

Stable and reliable production control

This intelligent system reduces operator dependency while improving production accuracy and consistency.

Accurate Batching and Mixing for Superior Product Quality

The production line is equipped with PL800-II concrete batching machine and a JS500 forced concrete mixer, ensuring uniform material blending and precise mix ratios.

An integrated water spray device automatically regulates the water–cement ratio, improving surface finish and consistency of pavers and curbstones.

Automated Production Line Configuration

Automated Stacking System

The automatic stacker and wet block conveyor ensure smooth product transfer and precise stacking, significantly reducing labor requirements.

Automatic Pallet Provider

The automatic pallet provider ensures continuous and stable pallet feeding to the block making machine, eliminating manual pallet handling and preventing production interruptions.

Together, these systems create a highly efficient and uninterrupted production flow.

Flexible Mould Options for Diverse Products

The QT6-15 plant supports a wide range of moulds, allowing manufacturers to respond quickly to market demand.

Standard rectangular pavers:

An integrated water spray device automatically regulates the water–cement ratio, improving surface finish and consistency of pavers and curbstones.

Automated Production Line Configuration

Automated Stacking System

The automatic stacker and wet block conveyor ensure smooth product transfer and precise stacking, significantly reducing labor requirements.

Automatic Pallet Provider

The automatic pallet provider ensures continuous and stable pallet feeding to the block making machine, eliminating manual pallet handling and preventing production interruptions.

Together, these systems create a highly efficient and uninterrupted production flow.

Flexible Mould Options for Diverse Products

The QT6-15 plant supports a wide range of moulds, allowing manufacturers to respond quickly to market demand.

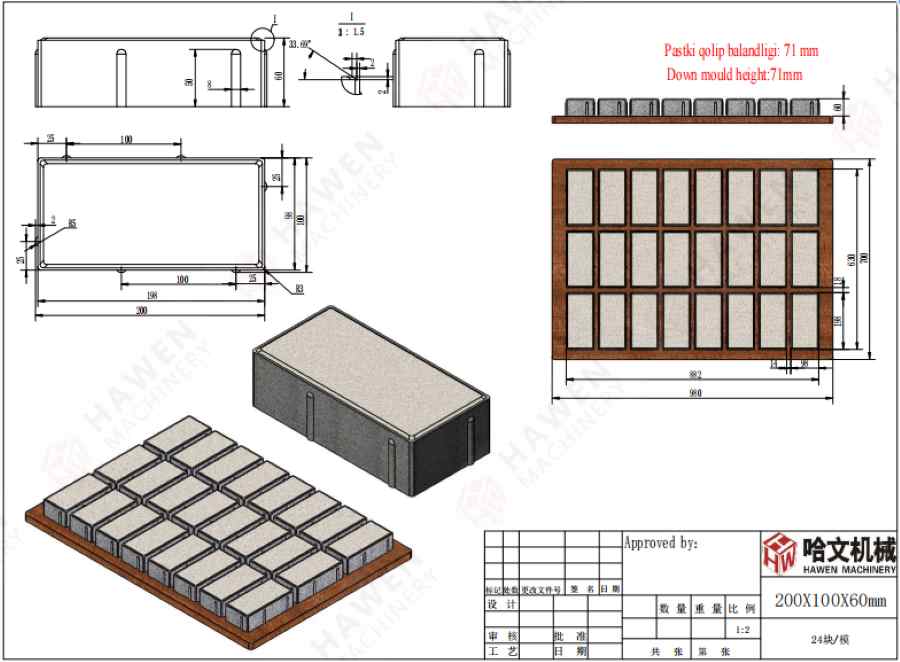

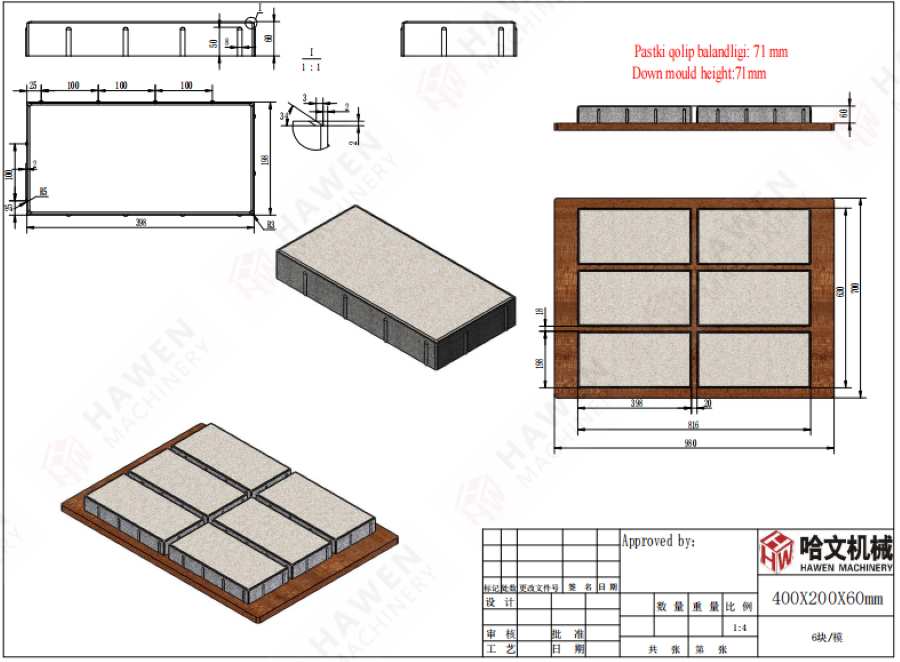

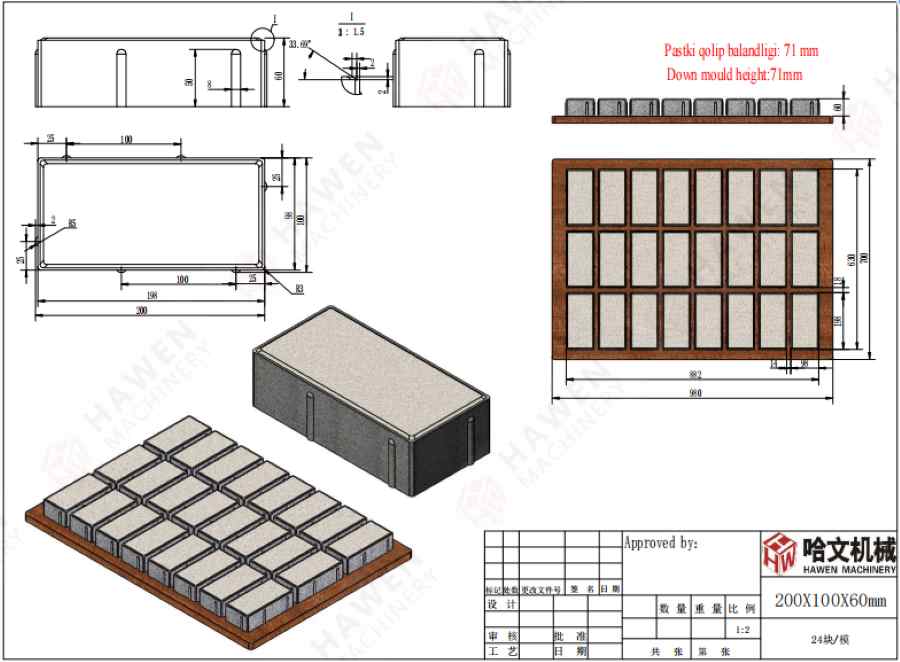

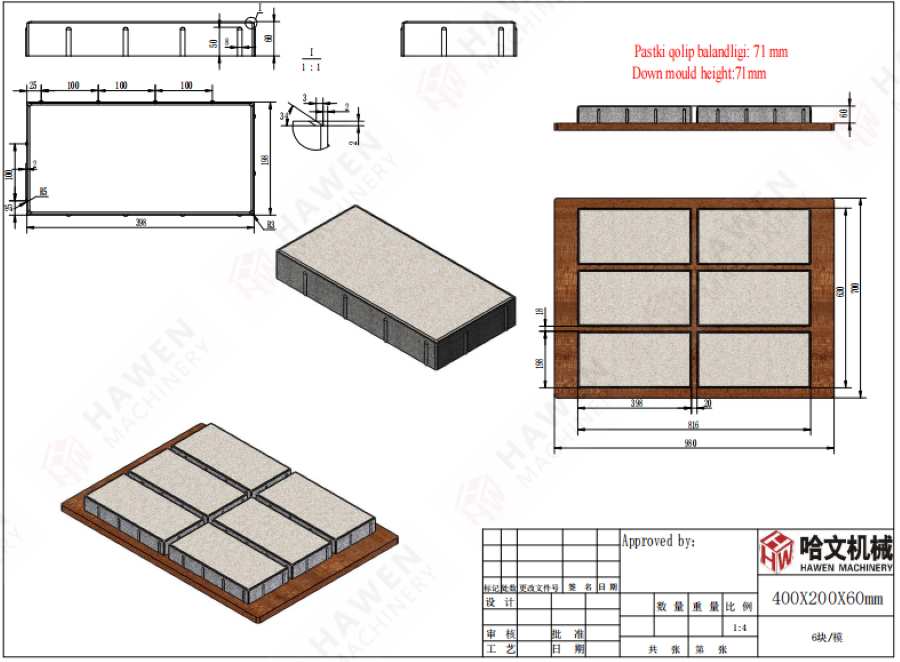

Standard rectangular pavers:

200 × 100 × 60 mm — 24 pcs/mould

200 × 200 × 60 mm — 12 pcs/mould

400 × 200 × 60 mm — 6 pcs/mould

Combination rectangular pavers:

180 × 120 × 40 mm

120 × 120 × 40 mm

120 × 90 × 40 mm

(10 pcs/mould each)

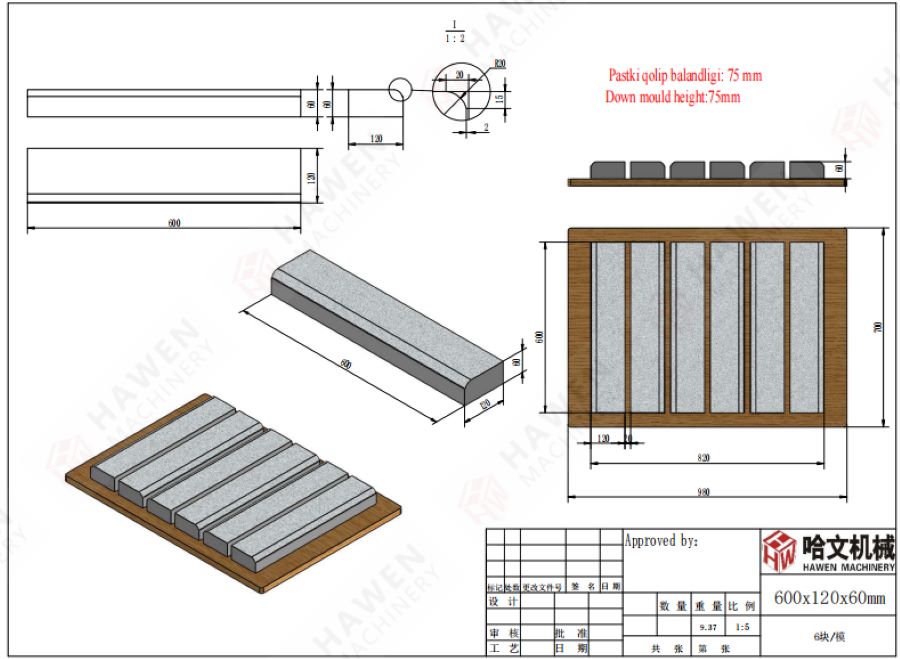

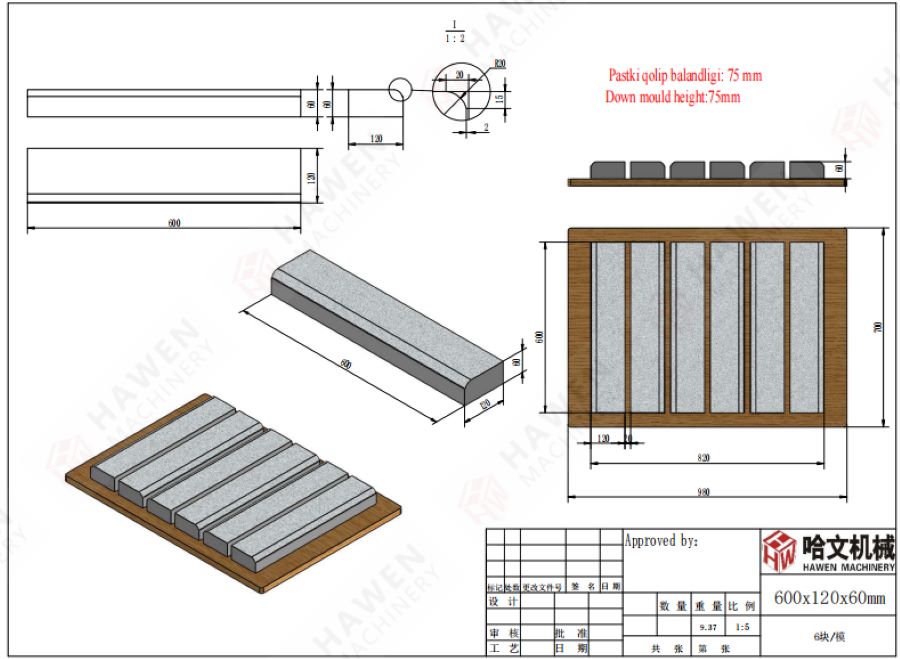

Curbstones:

600 × 120 × 60 mm — 6 pcs/mould

By changing moulds, the plant can also produce hollow blocks, solid bricks, and other concrete products on the same production line.

High Production Efficiency

Depending on material composition, the QT6-15 plant can produce:

Up to 35,000 pieces of 200 × 100 × 60 mm pavers per 8-hour shift, or

Up to 9,000 pieces of 400 × 200 × 200 mm hollow blocks per 8-hour shift

This high output makes the QT6-15 an excellent solution for medium to large-scale concrete product factories.

Energy-Efficient and Low-Maintenance Design

The optimized hydraulic and vibration systems reduce energy consumption and mechanical wear.

Key components from Siemens and YUKEN ensure long service life, easy maintenance, and reliable long-term operation.

The QT6-15 Paver and Curb Stone Making Plant is engineered to deliver precision, efficiency, and reliability for modern concrete block production.

Whether for pavers, curbstones, or structural blocks, the QT6-15 provides manufacturers with a flexible, intelligent, and future-ready production solution.

HAWEN MACHINERY — Engineering Precision, Reliability, and Innovation in Block Production.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China