How to make high-quality Concrete Curb Stone?

Curb stone,also known as Kerb Stone or Edge Stone,which is used to define the edge between a pavement and a roadway or landscape area. They serve both functional and aesthetic purposes in urban infrastructure.

Producing high-quality curb stones requires the integration of advanced manufacturing equipment, precise material handling, and durable mould technology. Hawen Machinery, a leading manufacturer of concrete block and curb stone production equipment, provides a comprehensive solution to achieve premium curb stone output.

✅ Key Factors for High-Quality Curb Stone Production:

1. Accurate Raw Material Mixing with Planetary Mixer

A planetary mixer is essential for achieving a homogenous concrete mix. Its unique mixing mechanism ensures:

Even distribution of cement, aggregates, and water

No dead zones or uneven patches

Improved compaction and strength in the finished curb stones

Hawen planetary mixers are designed for high efficiency and consistent quality, which directly impacts the final surface finish and durability of curb stones.

2. Good Vibration System for Compaction

Compaction plays a critical role in forming dense and crack-resistant curb stones.

Hawen Machinery equips its curb stone production lines with a good vibration system that features:

Four-shaft vibration box with High-frequency, synchronized vibrators

Variable vibration control for different mould types

Strong vibration force for deep and uniform compaction

This advanced vibration ensures each curb stone has a solid core, smooth surface, and high compressive strength.

3. High Quality Mould for Precision and Durability

The mould defines the final shape, texture, and dimensional accuracy of the curb stone.

Hawen’s high-quality moulds are manufactured using:

CNC-machined steel frames

Heat-treated and wear-resistant surfaces

Customizable profiles for different curb shapes (e.g., straight, rounded, sloped)

High-quality moulds reduce maintenance downtime and extend the life of the production line.

4. Use High-Quality Raw Materials

Cement: Use high-grade Portland cement.

Aggregates: Well-graded crushed stone and washed sand.

Water: Clean, free of impurities.

Additives: Water-reducing agents, pigments (for colored curb stones), and plasticizers to improve workability and strength.

5. Controlled Curing Process

Place molded curb stones in a steam curing chamber (recommended ) for 8–12 hours to accelerate hardening and strength development.

Maintain temperature and humidity to avoid cracking and ensure uniform curing.

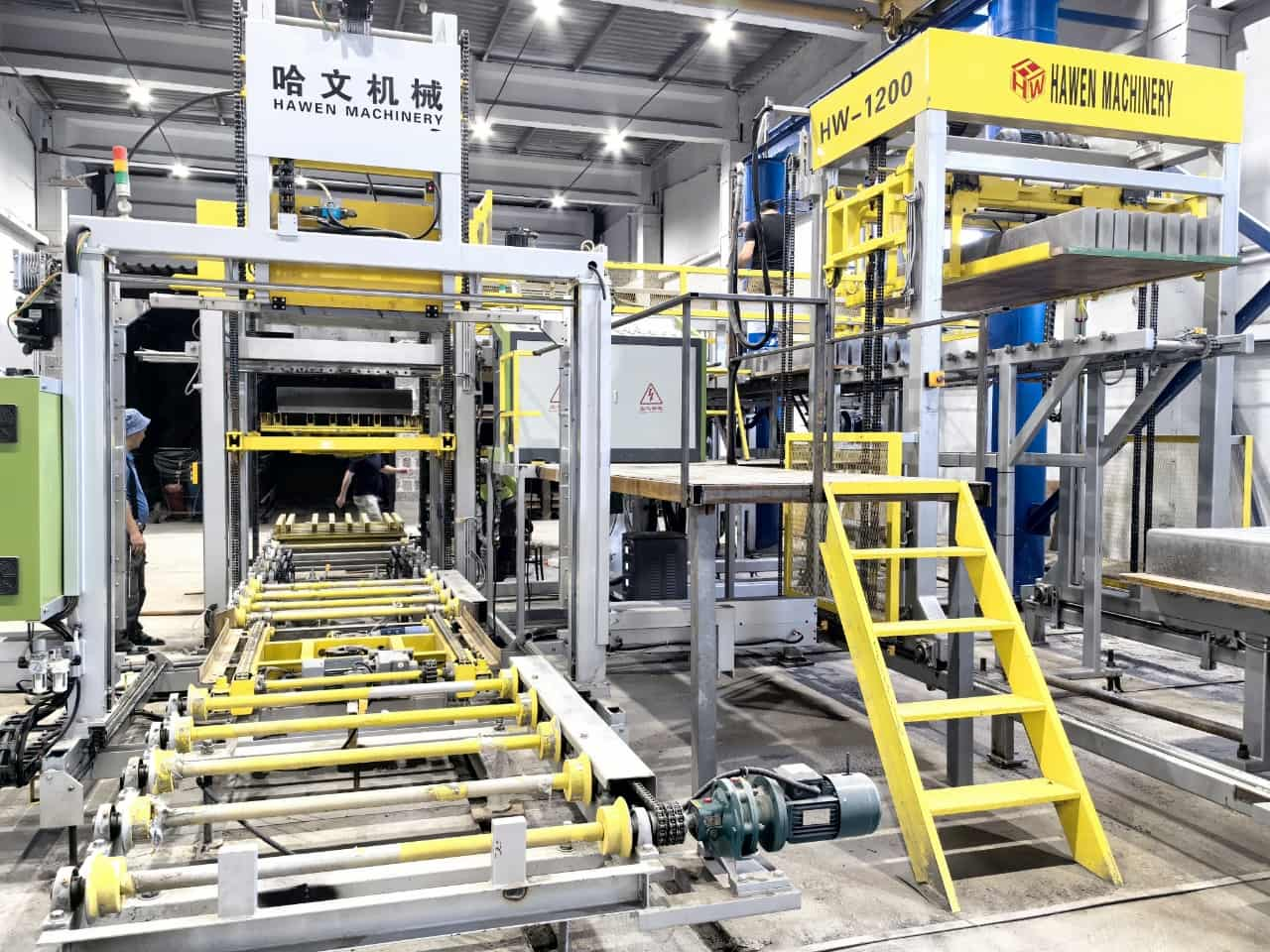

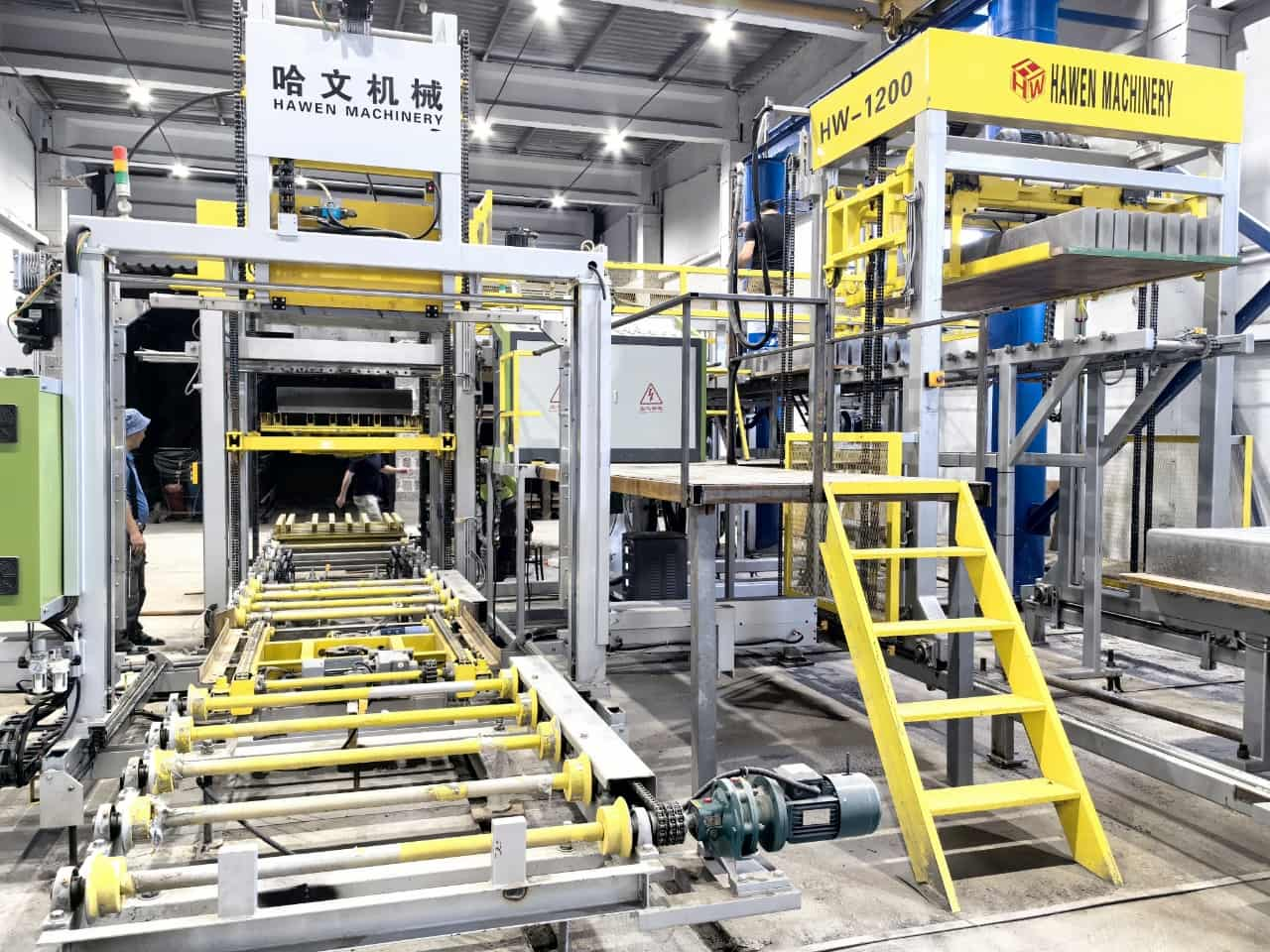

6.Automatic Cuber System – Efficient Handling and Stacking

For high-efficiency and safe material handling, Hawen’s automatic cuber system provides:

Fully automated pick-and-place operation

Programmable stacking patterns

Integration with finger cart and curing chamber systems(Optional)

The automatic cuber system reduces labor costs, prevents product damage, and boosts output speed.

Automated Curb stone Production Line by Hawen Machinery

To ensure consistent and scalable curb stone production, Hawen Machinery provides fully automated curb stone machines featuring:

Feeding and distribution systems for controlled material flow

Vibration and hydraulic pressing systems for accurate compaction

Curing solutions and stacking systems for efficient processing

The integration of these technologies results in uniform, aesthetically pleasing, and long-lasting curb stones.

Why Choose Hawen Machinery for Curb Stone Production?

※Over 20 years of experience in concrete block and curb stone machinery.

※High-performance machines designed for low maintenance and long lifespan.

※Professional installation, training, and technical support worldwide.

※Proven successful project cases in Russia, Middle East, Africa, and Southeast Asia.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China