Which Block Machine Capacity Fits Your Production Needs?

Author:HAWEN Block MachineFROM:Brick Production Machine Manufacturer

TIME:2026-01-28

Which Block Machine Capacity Fits Your Production Needs?

In the concrete block manufacturing industry, selecting the right block machine capacity is not merely a technical decision—it is a strategic one. Capacity determines not only output volume, but also capital efficiency, operational stability, and long-term competitiveness. An oversized machine may lead to underutilized investment, while insufficient capacity can constrain growth and inflate unit costs. Understanding how to align machine capacity with actual production needs is therefore essential.

Understanding Capacity Beyond Output Numbers

Block machine capacity is often simplified into hourly or daily production figures. However, capacity should be understood as a composite indicator rather than a single number. It reflects mold configuration, vibration efficiency, cycle time, automation level, and labor organization. A machine rated for high output but operated under unstable material supply or inconsistent batching conditions may fail to achieve its theoretical capacity. Therefore, realistic capacity planning must consider both machine performance and operational environment.

Small to Medium Capacity: Flexibility and Risk Control

For emerging markets, start-up plants, or manufacturers with diversified product requirements, small to medium-capacity block machines often provide the optimal balance. These machines offer lower initial investment, faster installation, and greater flexibility in mold changes. More importantly, they allow operators to validate market demand without excessive financial exposure. When designed with reliable vibration systems and stable hydraulics, medium-capacity machines can deliver consistent quality while maintaining manageable operating costs.

High Capacity Systems: Efficiency Through Scale

Large-capacity block machines are best suited for mature markets with stable demand and standardized product lines. Their advantage lies in economies of scale: lower labor cost per unit, higher energy efficiency per block, and greater consistency in mass production. However, high-capacity systems also require advanced automation, robust structural design, and highly stable control systems. Without these foundations, increased speed may amplify mechanical stress and operational risk rather than efficiency.

Small to Medium Capacity: Flexibility and Risk Control

For emerging markets, start-up plants, or manufacturers with diversified product requirements, small to medium-capacity block machines often provide the optimal balance. These machines offer lower initial investment, faster installation, and greater flexibility in mold changes. More importantly, they allow operators to validate market demand without excessive financial exposure. When designed with reliable vibration systems and stable hydraulics, medium-capacity machines can deliver consistent quality while maintaining manageable operating costs.

High Capacity Systems: Efficiency Through Scale

Large-capacity block machines are best suited for mature markets with stable demand and standardized product lines. Their advantage lies in economies of scale: lower labor cost per unit, higher energy efficiency per block, and greater consistency in mass production. However, high-capacity systems also require advanced automation, robust structural design, and highly stable control systems. Without these foundations, increased speed may amplify mechanical stress and operational risk rather than efficiency.

Matching Capacity with Long-Term Strategy

Choosing capacity should always align with long-term business planning rather than short-term output targets. Factors such as market expansion potential, raw material availability, labor skill level, and maintenance capability must be evaluated holistically. A well-matched machine capacity allows manufacturers to scale production smoothly, avoid frequent equipment replacement, and preserve operational continuity as demand evolves.

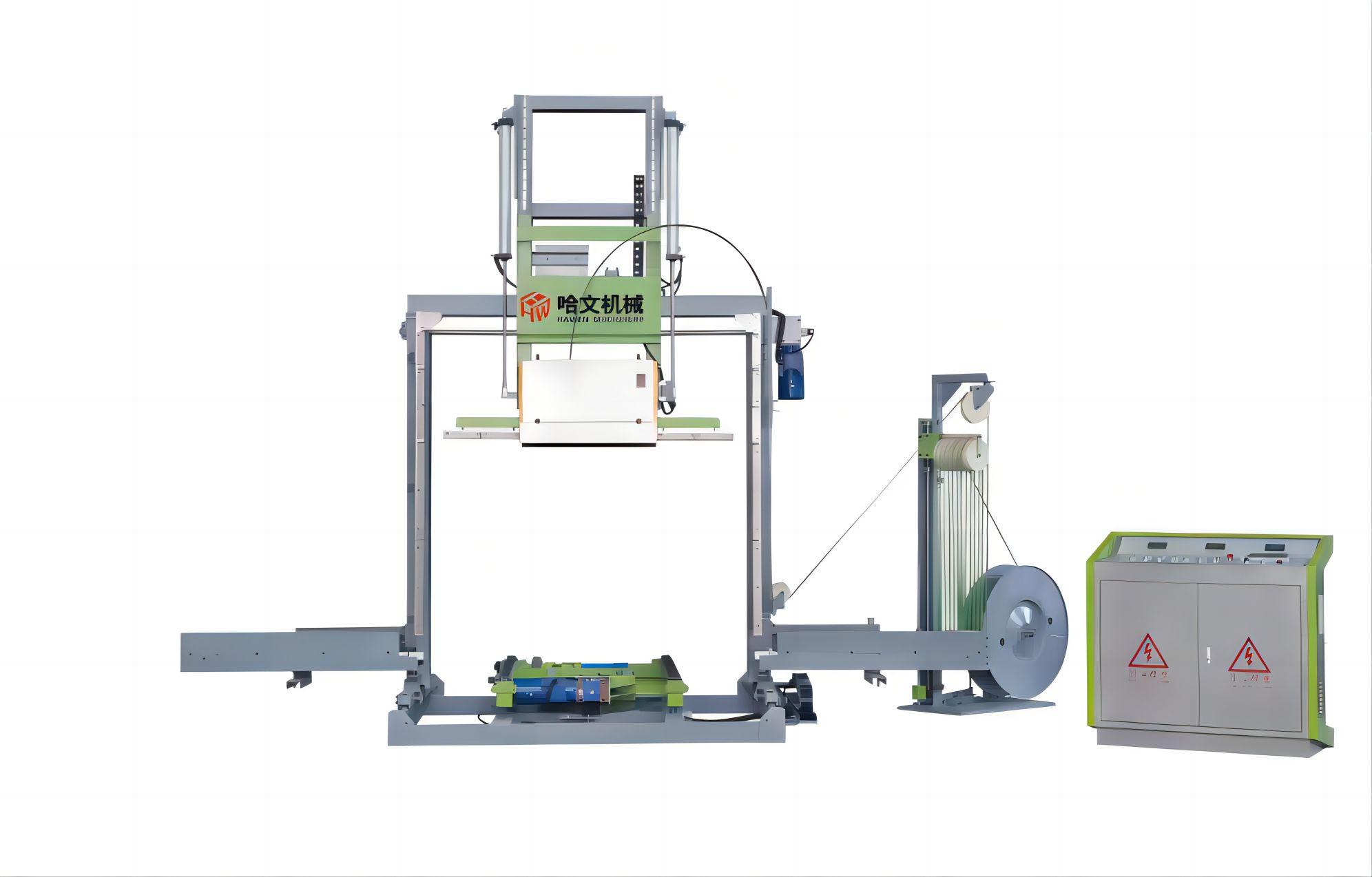

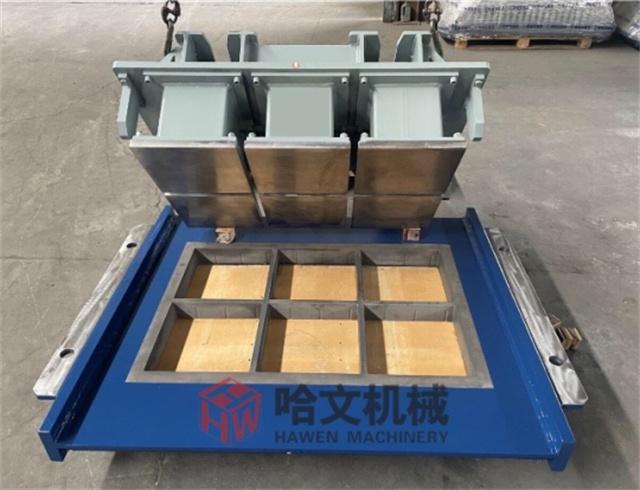

Hawen Machinery: Capacity Designed for Stability

At Hawen Machinery, capacity design is guided by stability rather than sheer output figures. From medium-capacity machines optimized for versatility to large-scale systems engineered for continuous industrial production, Hawen integrates reinforced mechanical structures, efficient vibration systems, and independently controlled hydraulic stations. This ensures that rated capacity is not only achievable on paper, but sustainable in long-term operation. Capacity, in this context, becomes a reliable promise rather than an aggressive estimate.

Matching Capacity with Long-Term Strategy

Choosing capacity should always align with long-term business planning rather than short-term output targets. Factors such as market expansion potential, raw material availability, labor skill level, and maintenance capability must be evaluated holistically. A well-matched machine capacity allows manufacturers to scale production smoothly, avoid frequent equipment replacement, and preserve operational continuity as demand evolves.

Hawen Machinery: Capacity Designed for Stability

At Hawen Machinery, capacity design is guided by stability rather than sheer output figures. From medium-capacity machines optimized for versatility to large-scale systems engineered for continuous industrial production, Hawen integrates reinforced mechanical structures, efficient vibration systems, and independently controlled hydraulic stations. This ensures that rated capacity is not only achievable on paper, but sustainable in long-term operation. Capacity, in this context, becomes a reliable promise rather than an aggressive estimate.

Conclusion: Capacity as a Measure of Industrial Maturity

Ultimately, the right block machine capacity reflects a manufacturer's understanding of its own production realities. It is a measure of industrial maturity, not ambition alone. When capacity selection is grounded in realistic assessment, supported by stable machine design, and aligned with strategic vision, productivity becomes predictable and growth becomes durable. In modern block manufacturing, the most successful operations are not those that pursue maximum capacity, but those that choose the right capacity—and make it work consistently.

Conclusion: Capacity as a Measure of Industrial Maturity

Ultimately, the right block machine capacity reflects a manufacturer's understanding of its own production realities. It is a measure of industrial maturity, not ambition alone. When capacity selection is grounded in realistic assessment, supported by stable machine design, and aligned with strategic vision, productivity becomes predictable and growth becomes durable. In modern block manufacturing, the most successful operations are not those that pursue maximum capacity, but those that choose the right capacity—and make it work consistently.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China