QT12 Block Making machine Shipped to Customer in Ukraine

Shipment Overview

The QT12 block making machine had been carefully loaded into a 40' frame rack on 28 November 2025, with each component professionally reinforced and secured to prevent movement or damage during transit. Sea freight shipping is scheduled to begin on 5 December 2025, with an estimated transit time of approximately one month to reach the designated port in Ukraine.

Shipment Overview

The QT12 block making machine had been carefully loaded into a 40' frame rack on 28 November 2025, with each component professionally reinforced and secured to prevent movement or damage during transit. Sea freight shipping is scheduled to begin on 5 December 2025, with an estimated transit time of approximately one month to reach the designated port in Ukraine.

Core Systems Overview

The QT12 block production line is designed for stable, high-efficiency operation and user-friendly management, consisting of following main systems:

Main Machine System

The core forming unit features a high-strength steel frame and advanced vibration-pressing mechanism, ensuring precise block forming with consistent density and durability.

Core Systems Overview

The QT12 block production line is designed for stable, high-efficiency operation and user-friendly management, consisting of following main systems:

Main Machine System

The core forming unit features a high-strength steel frame and advanced vibration-pressing mechanism, ensuring precise block forming with consistent density and durability.

Main forming system with facemix device

This system comprises aggregate feeding mechanisms, material distributors, and the Face Mix Device, which allows precise application of surface material for pavers. It ensures high-quality surface finishes and uniform block appearance.

The main frame is built with 200×150 mm heavy-duty steel tubes to ensure exceptional rigidity and durability. The machine is equipped with an electric lifting mechanism for the aggregate platform, allowing effortless height adjustment when switching between hollow block and paver moulds. A hydraulic lifting system is provided for the face-mix platform, together with an electric traveling mechanism that enables the face-mix device to move forward smoothly during mould changes. In addition, an airbag clamping device is included for quick and secure fastening of the down mould.

Main forming system with facemix device

This system comprises aggregate feeding mechanisms, material distributors, and the Face Mix Device, which allows precise application of surface material for pavers. It ensures high-quality surface finishes and uniform block appearance.

The main frame is built with 200×150 mm heavy-duty steel tubes to ensure exceptional rigidity and durability. The machine is equipped with an electric lifting mechanism for the aggregate platform, allowing effortless height adjustment when switching between hollow block and paver moulds. A hydraulic lifting system is provided for the face-mix platform, together with an electric traveling mechanism that enables the face-mix device to move forward smoothly during mould changes. In addition, an airbag clamping device is included for quick and secure fastening of the down mould.

Hydraulic System (including Oil-Cooler)

The hydraulic system includes American ALBERT hydraulic pumps, Japanese Yuken hydraulic valves, pressure control units, and an integrated Oil-Cooler, which maintains optimal hydraulic oil temperature during extended production. This guarantees stable and continuous operation even under heavy workloads.

Control System

Equipped with an advanced German Siemens PLC platform and Switzerland ABB relays, the QT12 features a Russian-language control panel customized for the customer,easy for russian-speaking countries client during the machine operation.

The intuitive interface reduces training time and enables precise control of the entire production line.

Hydraulic System (including Oil-Cooler)

The hydraulic system includes American ALBERT hydraulic pumps, Japanese Yuken hydraulic valves, pressure control units, and an integrated Oil-Cooler, which maintains optimal hydraulic oil temperature during extended production. This guarantees stable and continuous operation even under heavy workloads.

Control System

Equipped with an advanced German Siemens PLC platform and Switzerland ABB relays, the QT12 features a Russian-language control panel customized for the customer,easy for russian-speaking countries client during the machine operation.

The intuitive interface reduces training time and enables precise control of the entire production line.

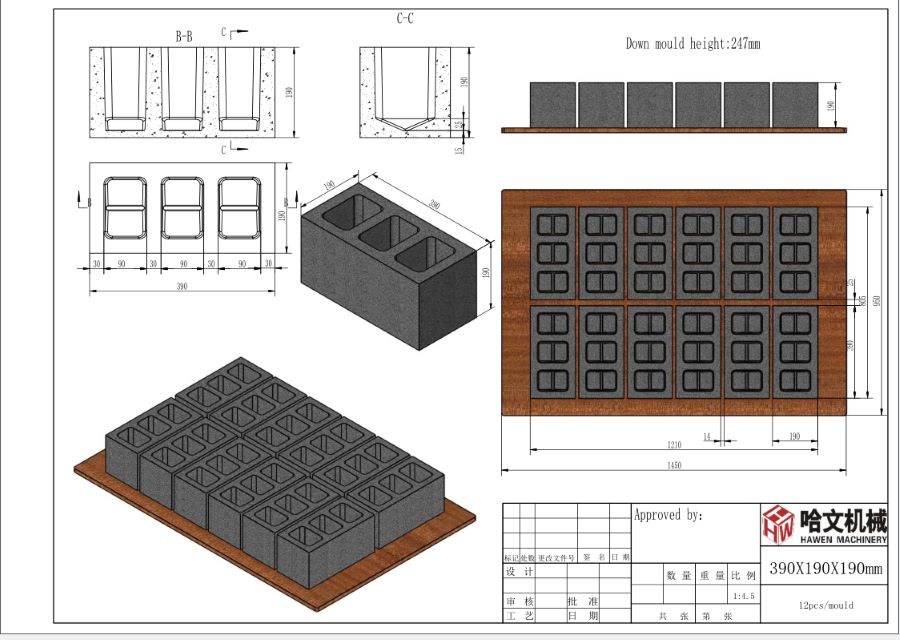

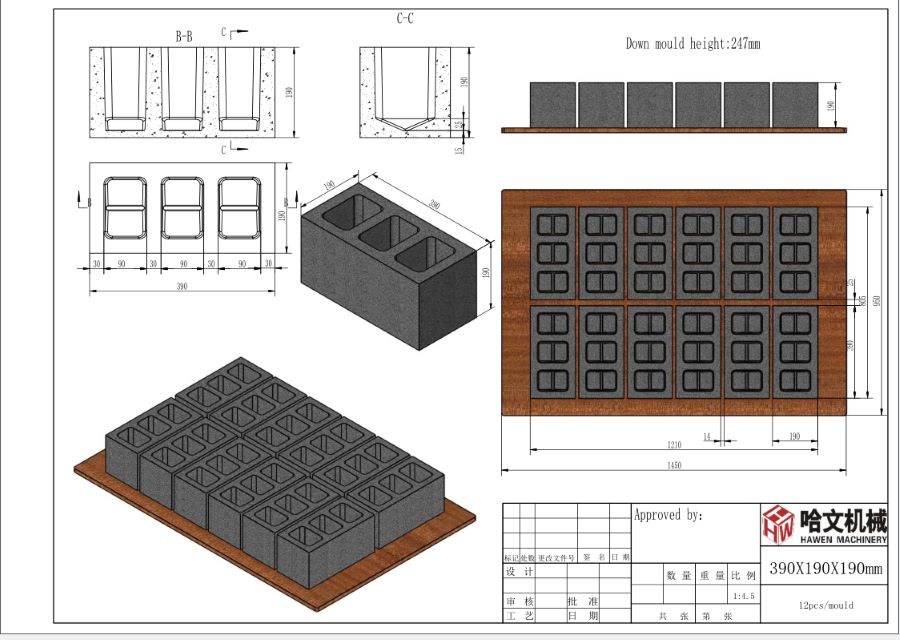

Additional Moulds Supplied

In addition to the two tested paver mould sets, the machine is supplied with a hollow block mould(390 × 190 × 190 mm 12pcs/mould), a widely used standard size in construction. This allows the customer to produce high-strength hollow blocks suitable for walls and structural applications.

Additional Moulds Supplied

In addition to the two tested paver mould sets, the machine is supplied with a hollow block mould(390 × 190 × 190 mm 12pcs/mould), a widely used standard size in construction. This allows the customer to produce high-strength hollow blocks suitable for walls and structural applications.

Factory Testing

Prior to shipment, the machine underwent comprehensive operational testing, including vibration, hydraulic, electrical, and trial block production.

Factory Testing

Prior to shipment, the machine underwent comprehensive operational testing, including vibration, hydraulic, electrical, and trial block production.

Paver Mould 01: 300 × 200 × 40 mm, 250 × 200 × 40 mm, 200 × 200 × 40 mm, 150 × 200 × 40 mm

Paver Mould 02: 180 × 120 × 40 mm, 120 × 120 × 40 mm, 120 × 90 × 40 mm, 120 × 60 × 40 mm

These tests confirmed the machine’s forming accuracy, stability, and output quality.During commissioning, we also preset and saved all the production parameters for each brick type in the touch screen. When the customer starts production, they can simply load the corresponding parameter settings and make only minor adjustments if needed.

Pallet Specification

The system uses GMT pallets sized 1450 × 950 mm, providing robust support and stability under high-frequency vibration.

Future Outlook — Supporting Post-War Reconstruction

The QT12 production line is expected to play a key role in rebuilding Ukraine’s infrastructure and communities. With its high production capacity, the plant will:

Produce millions of pavers and hollow blocks annually to support large-scale reconstruction projects

Supply materials for multiple infrastructure, residential, and commercial construction initiatives

Create local employment opportunities through the new brick production facility

Strengthen the availability of high-quality building materials, accelerating regional recovery and urban redevelopment

By choosing Hawen Machinery, the customer gains a long-term, sustainable solution that not only meets immediate production needs but also supports economic growth and reconstruction efforts in Ukraine over the coming years.

By choosing Hawen Machinery, the customer gains a long-term, sustainable solution that not only meets immediate production needs but also supports economic growth and reconstruction efforts in Ukraine over the coming years.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China