-

Enhanced Efficiency and Productivity. Cost-Effectiveness. Consistent Quality and Durability. Flexibility and Customization. Environmental Benefits. Ease of Maintenance and Operation. Conclusion....

masonry block making machine

-

Cement: The Foundation of Paver Blocks. Aggregates: The Structural Backbone. Water: Essential for Mixing and Curing. Additives and Chemical Admixtures: Enhancing Properties. Reinforcement Materials: S...

interlocking paver block making machine

-

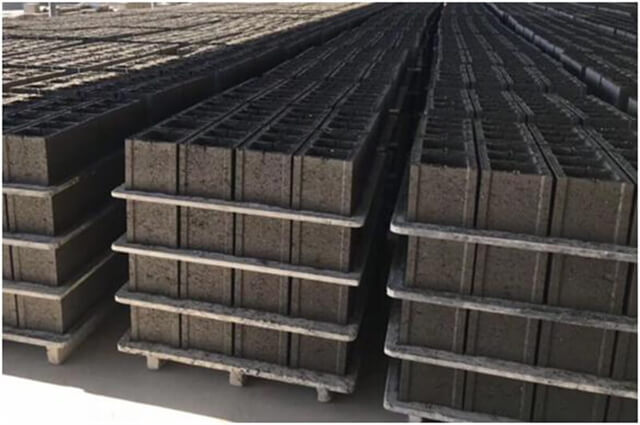

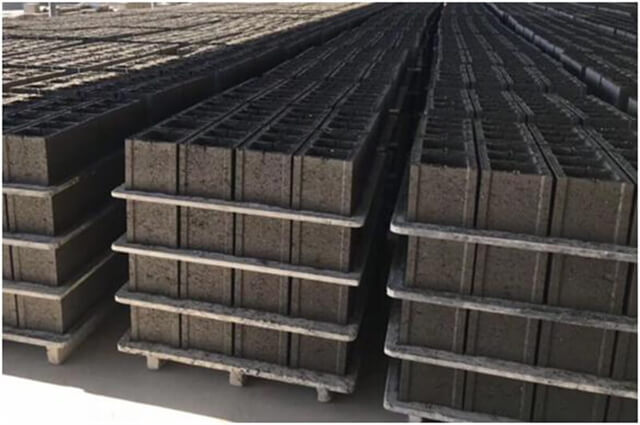

Understanding Hollow Block Making Machines. Capabilities of Hollow Block Making Machines. Production of Paving Blocks. Production of Solid Bricks. Advantages and Limitations. Conclusion....

hollow block making machine

-

1. Research and Understand the Machine Specifications. 2. Evaluate the Manufacturer's Reputation. 3. Assess Machine Durability and Construction Quality. 4. Inspect Automation and Control Systems. 5. V...

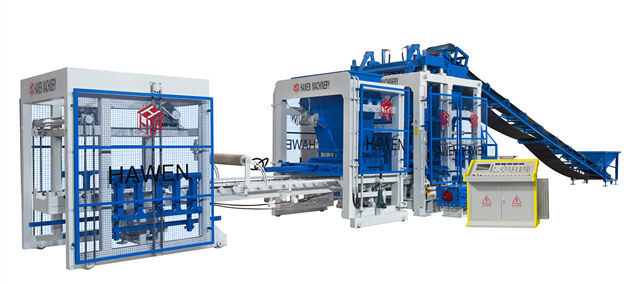

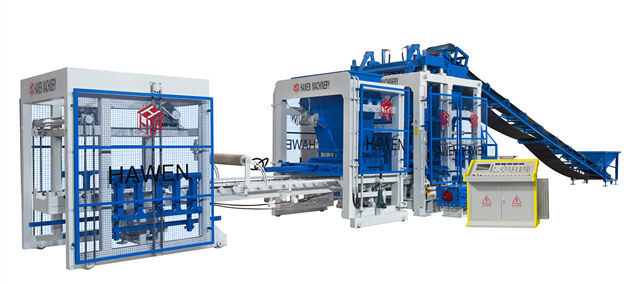

automatic block making machine

-

1. Raw Material Preparation. 2. Mixing and Pouring. 3. Compaction. 4. Curing. 5. Demolding. 6. Finishing. 7. Stacking and Packaging. 8. Quality Control. Conclusion. ...

Block Machine

-

1. Design and Engineering. 2. Material Selection. 3. Fabrication of Components. 4. Assembly and Integration. 5. Testing and Quality Assurance. 6. Performance Optimization. 7. Training and Documentatio...

Compressed Earth Block Making Machine

-

1. Design and Engineering. 2. Material Selection. 3. Machining and Fabrication. 4. Hydraulic System Integration. 5. Electrical Assembly. 6. Testing and Calibration. 7. Finishing and Painting. 8. Packa...

Concrete Paver Block Making Machine

-

Component Manufacturing. Assembly Stage. Testing Stage. Packaging and Shipping Stage. Site Preparation Stage. Raw Material Preparation Stage. Block Production Stage. Maintenance Stage. Conclusion....

Hydraulic Block Making Machine

-

The QT6 block machine is amazing! It has a great production capacity and its blocks are of excellent quality. Highly recommend...

Block Making Machine

-

Compared to other machines in the market, the QT10-15 offers better value for money. We're happy with our purchase. ...

-

The Hawen block making machine is efficient and reliable. It has exceeded my expectations!...

-

1. Setting Up the Machine. 2. Assembly and Connection. 3. Testing and Calibration. 4. Routine Inspection. 5. Lubrication and Cleaning. 6. Preventive Maintenance. 7. Safety Measures. 8. Troubleshooting...

concrete block making machine

-

1. Machine Design. 2. Raw Material Selection. 3. Automation. 4. Quality Control. 5. Energy Efficiency. 6. Training and Skilled Workforce. 7. Continuous Improvement. 8. Collaboration with Suppliers. Co...

Industrial Block Making Machine

-

Installation. Foundation. Startup and Operation. Maintenance. Troubleshooting. Safety Precautions. Environmental Protection. Conclusion....

Hydraulic Block Making Machine

-

1. Site Preparation. 2. Foundation Construction. 3. Machine Assembly. 4. Electrical and Hydraulic Connections. 5. Testing and Calibration. 6. Regular Cleaning and Lubrication. 7. Inspection and Repair...

Industrial Block Making Machine

-

Understanding the Components. Preparation and Site Selection. Assembling the Machine. Electrical Connection and Testing. Operational Training. Maintenance and Troubleshooting. Safety Considerations. C...

lock Making Machine

-

1. History of Hollow Block Making Machine. 2. Components of the Hollow Block Making Machine. 3. Working Principle of the Hollow Block Making Machine. 4. Types and Sizes of Hollow Blocks. 5. Advantages...

Hollow Block Making Machine

-

Introduction. Enhanced Productivity. Precision and Consistency. Energy Efficiency. Versatility in Block Design. Quality Assurance. User-Friendly Interface. Remote Monitoring and Maintenance. Conclusio...

Concrete Block Making Machine

-

Installation Process. Foundation Preparation. Machine Configuration. Machine Start-up. Maintenance Schedule. Cleaning. Lubrication. Replacement of Parts. Conclusion....

Concrete Paver Block Making Machine

-

Introduction. 1. Cleaning and Lubrication. 2. Inspection and Repair of Wear Parts. 3. Calibration and Alignment. 4. Training and User Manual. 5. Prompt Technical Support. 6. Availability of Spare Part...

Block Machine

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China