-

Enhancing Construction Efficiency. Quality Control. Diverse Block Designs. Cost Savings. Environmental Sustainability. Ease of Operation and Maintenance. Adaptability to Various Scales of Production. ...

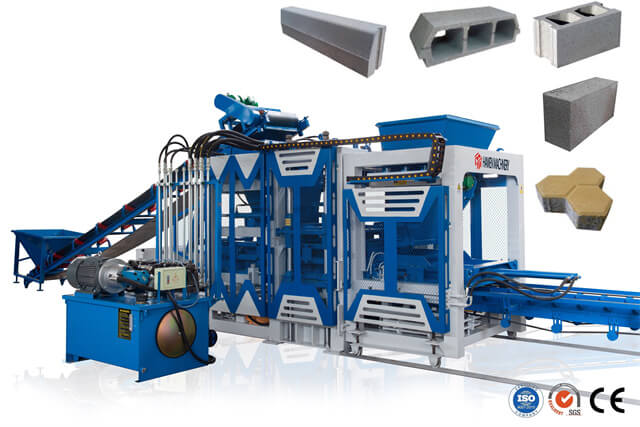

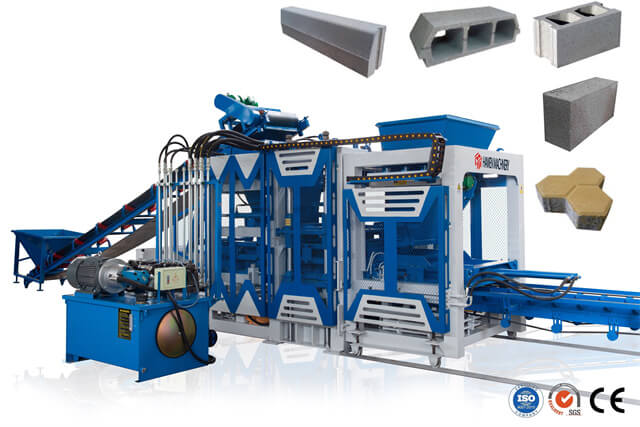

Cement Block Making Machines

-

1. Introduction. 2. Components of Cement Block Making Machines. 3. Functionality of the Hopper. 4. Role of the Mixer. 5. Importance of the Conveyor Belt. 6. Functionality of the Block Molds. 7. Role o...

block making machine

-

.jpg)

1. Production Capacity. 2. Quality of Blocks. 3. Ease of Use. 4. Maintenance and Repair. 5. Power Requirements. 6. Cost. 7. Brand Reputation. 8. Customization Options. Conclusion....

Automatic Block Making Machine

-

Advanced Technology. High Productivity. Versatile Design. Energy-Efficient Operation. Durable Construction. User-Friendly Controls. Customization Options. Conclusion....

Concrete Block Making Machine

-

1. High Efficiency. 2. Energy-efficient. 3. Precision Engineering. 4. Versatility. 5. Cost-effective. 6. Excellent Insulation properties. 7. Fire and Pest Resistance. 8. Environmentally-friendly. Conc...

AAC Block Making Machine

-

Structure of Manual Block Making Machine. Block Making Process. Block Sizes and Shapes. Advantages of Manual Block Making Machines. Disadvantages of Manual Block Making Machines. Maintenance of Manual...

Manual Block Making Machine

-

Early Development. Integration of Advanced Technologies. Modern Design Principles. Working Principle: Raw Material Preparation. Working Principle: Block Formation. Working Principle: Curing and Stacki...

Automatic Block Making Machine

-

1. Understanding the Machine. 2. Types of Cinder Blocks. 3. The Cinder Block Making Process. 4. Ensuring Quality Control. 5. Safety Precautions. 6. Increasing Productivity. 7. Troubleshooting and Main...

Cinder Block Making Machine

-

1. Efficiency. 2. Versatility. 3. Durability. 4. Precision. 5. Cost-effective. 6. User-friendly. 7. Environmental-friendly. 8. Scalability. Conclusion. ...

block making machine

-

.jpg)

1. Understanding the Machine. 2. Preparation and Setup. 3. Operating the Machine. 4. Monitoring and Adjusting. 5. Curing and Finishing. 6. Quality Control. 7. Utilization in Construction. 8. Maintenan...

Interlocking Block Making Machine

-

Introduction. Global Construction Industry Growth. Technology Advancements in Paver Block Making. Environmental Sustainability Driving Demand. Regional Market Trends. Challenges and Opportunities. Cus...

paver block making machine

-

1. Understanding Machine Components. 2. Selecting the Right Raw Materials. 3. Preparing the Machine. 4. Operating the Machine. 5. Maintaining Safety Measures. 6. Ensuring Proper Curing. 7. Quality Con...

Cement Block Making Machine

-

1. Growing Construction Industry. 2. Emphasis on Sustainable Building Practices. 3. Small-Scale Construction Enterprises. 4. Customization and Flexibility. 5. Affordable Housing Initiatives. 6. Techno...

block making machine

-

1. Introduction. 2. Growth of the Construction Industry. 3. Advantages of Concrete Blocks. 4. Technological Advancements. 5. Environmental Sustainability. 6. Regional Market Trends. 7. Key Players and...

Concrete Block Making Machine

-

.jpg)

Introduction. Understanding the Automatic Cement Block Making Machine. Preparation Before Operating the Machine. Operating the Machine. Maintenance and Troubleshooting. Safety Precautions. Quality Con...

Cement Block Making Machine

-

Introduction. 1. Machine Setup and Inspection. 2. Material Preparation. 3. Machine Operation. 4. Quality Control. 5. Maintenance and Cleaning. 6. Safety Precautions. 7. Troubleshooting. Conclusion. ...

brick making machine

-

.jpg)

1. Safety Precautions. 2. Machine Setup. 3. Preparation of Raw Materials. 4. Loading of the Mixture. 5. Operating the Machine. 6. Curing and Drying. 7. Quality Control. 8. Maintenance and Cleaning. Co...

brick making machine

-

.jpg)

Introduction. 1. Safety Precautions. 2. Machine Setup. 3. Mixing the Cement. 4. Block Production Process. 5. Cleaning and Maintenance. 6. Troubleshooting. 7. Cost and Efficiency. Conclusion....

Cement Block Making Machine

-

1. What is a Cinder Block Making Machine?. 2. Types of Cinder Block Making Machines. 3. Features and Components. 4. Advantages of Using Cinder Block Making Machines. 5. Applications of Cinder Block Ma...

Cinder Block Making Machine

-

1. High Production Capacity. 2. Customizable Block Sizes and Shapes. 3. Cost-Effective Solution. 4. High Durability. 5. Simple Operation and Maintenance. 6. Environmentally Friendly. 7. Precise Block ...

paver block making machine

.jpg)

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China