In July 2025, HAWEN Machinery successfully shipped a set of customized stoneface paver concrete moulds to a professional concrete product manufacturer in Uganda. The cooperation began in May 2025, when the client approached us with a requirement for a curved-surface, stone-textured paver mould compatible with their Italian block making machine. This was not a standard paver design; the client needed a finish that could meet both aesthetic appeal and structural durability for high-end architectural applications.

Given HAWEN's track record in providing customized block moulds for various global brands of block making machines, including MASA, HESS, GLOBMAC, POYATOS, TIGER, and BESSER, the customer was confident in our ability to deliver a tailor-made solution.

1. Contract Confirmation & Drawing Preparation

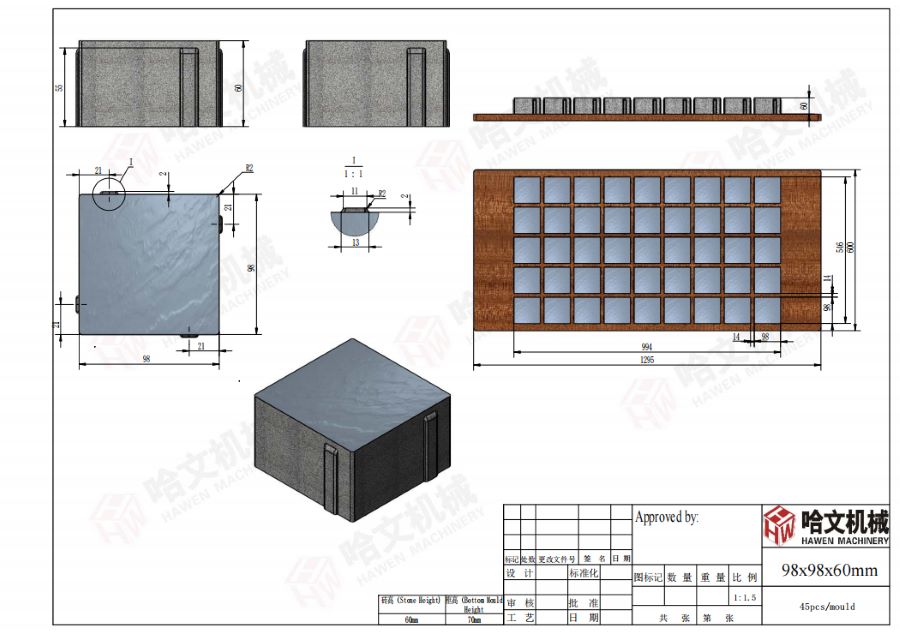

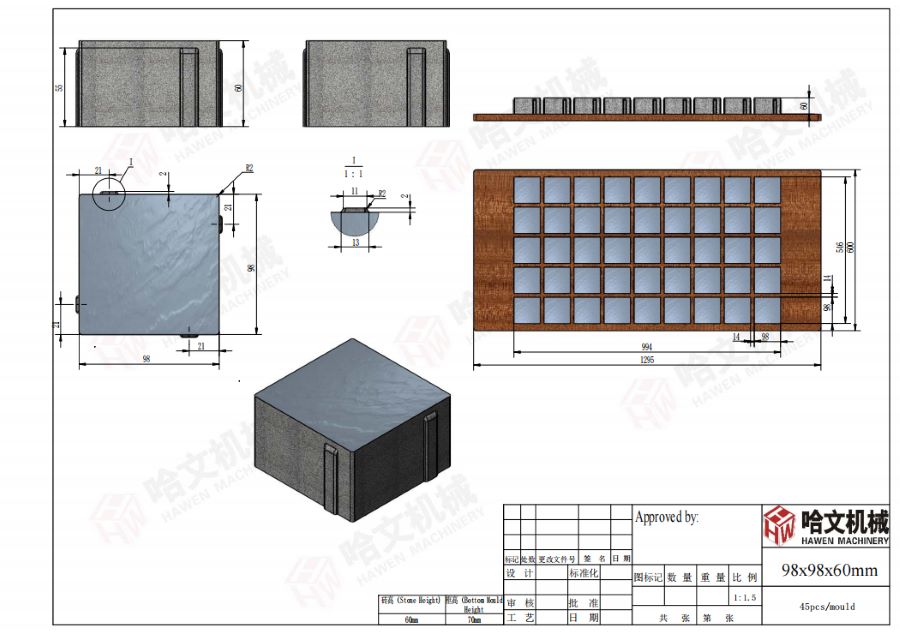

After technical discussions and reviewing reference designs, the client officially confirmed the order. HAWEN’s engineering team immediately began work on a detailed 3D drawing for the stoneface paver concrete mould, tailored specifically to fit the mechanical structure and vibration system of the Italian brick machine.

Key design considerations included:

Accurate cavity curvature to replicate a natural stoneface texture

Reinforced frame for stable production under long-term vibration cycles

Compatibility with automated demoulding systems in the Italian block making line

The client reviewed and approved the drawing quickly, appreciating our ability to combine aesthetic surface design with precision mechanical integration.

2. Concrete Mould Production & Progress Updates

Once the design was finalized, production began using premium wear-resistant alloy steel, processed with advanced CNC machining to ensure high-precision cavity shaping and structural uniformity.

To build client trust, HAWEN provided photo updates throughout the key stages of manufacturing:

Steel cutting

CNC cavity forming

Surface polishing for smooth demoulding

Assembly and welding of the mould frame

This transparent communication process ensured the customer remained informed and reassured about quality control.

3. Finished Mould Showcase

Upon completion, the stoneface paver concrete mould was photographed in detail and shared with the client. The finished product showed:

Curved stone-textured cavity walls, as requested

Sharp, clean cavity edges for accurate block shaping

Uniform surface finish to ensure smooth demoulding and consistent block appearance

The final result fully met the customer’s expectations for both visual and functional performance.

4. SGS Pre-Shipment Inspection

Before packing, the concrete mould underwent a third-party quality inspection by SGS. This included:

Dimensional accuracy check

Hardness and heat treatment verification

Surface finish evaluation

Assembly integrity test

The SGS inspection report and photos were shared with the client, serving as independent validation of our production standards.

5. Secure Packaging & Delivery to Uganda

Each stoneface paver concrete mould was:

Coated with anti-rust protection

Wrapped in protective foam

Packed into heavy-duty export wooden crates

The moulds were shipped by sea and successfully delivered to the client’s plant in Uganda. Installation and testing were handled locally with remote technical support from HAWEN’s engineering team.

Why More Customers Choose HAWEN Concrete Moulds

✅ Custom Engineering

Every HAWEN concrete mould is fully customized—from cavity dimensions to texture geometry—to match the exact requirements of the client’s brick and block making machines.

✅ Multi-Brand Compatibility

Our concrete moulds are adaptable to a wide range of international block machine brands such as Italian machines, MASA, HESS, POYATOS, TIGER, BESSER, and GLOBMAC.

✅ Stoneface Surface Expertise

With CNC capability and advanced polishing techniques, we can reproduce stone-textured surfaces with curved cavity geometry while maintaining demoulding efficiency.

✅ Durability & Longevity

Manufactured with hardened alloy steel, heat-treated and reinforced, our concrete moulds are designed for extended service life, even in high-output production lines.

✅ Quality Transparency

With real-time updates, detailed production photos, and optional third-party SGS inspection, our clients have full confidence in every mould they receive.

✅ Global Service Experience

From the Middle East to Southeast Asia and Africa, HAWEN Concrete Moulds are trusted by manufacturers worldwide for high-performance, precision-fit mould solutions.

At HAWEN Machinery, we understand that a concrete mould is more than just a tool—it’s a critical part of your block making system’s productivity and output quality. Whether you're producing hollow blocks, solid bricks, or decorative pavers, our moulds deliver the accuracy, strength, and reliability that professional concrete producers demand.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China