-

Block moulds are custom-designed components that shape the concrete mix into specific block shapes and sizes. These moulds are precision-engineered to create un...

-

The control panel serves as the interface for operating and monitoring the planetary concrete mixer, allowing for adjustments and real-time monitoring of th...

-

The hydraulic system powers the movement of various parts of the planetary concrete mixer, enabling precise control and efficient operation. ...

-

The mixing blades play a significant role in agitating and blending the components of the concrete, ensuring thorough and consistent mixing. ...

-

The discharge door allows for the controlled release of the mixed concrete, ensuring precision and accuracy during the brick making process. ...

-

The gearbox is a crucial component that facilitates the smooth and efficient operation of the planetary concrete mixer, providing the necessary torque and spe...

-

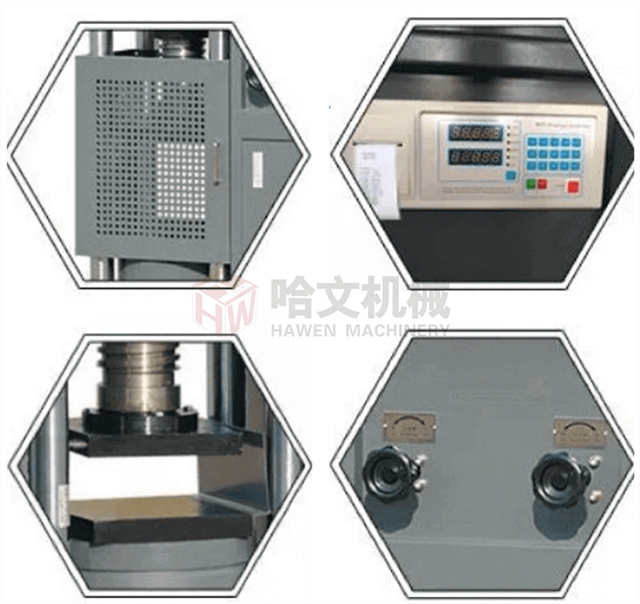

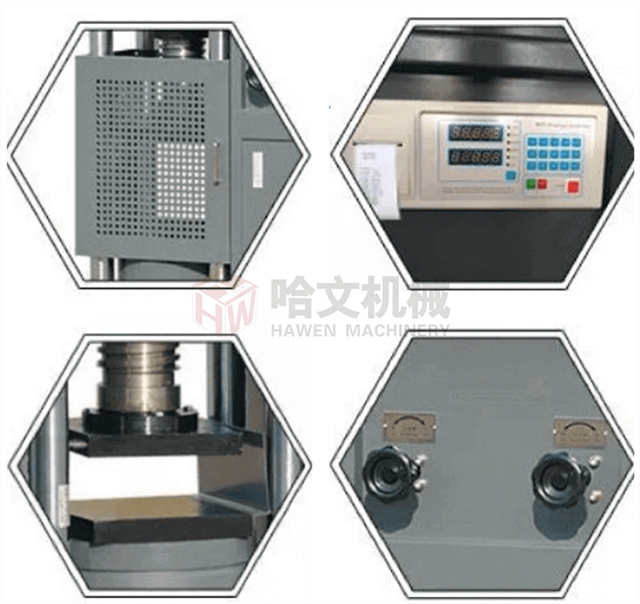

The load cell is a vital sensor that directly measures the compressive force applied to the block specimen. It converts the force into an electrical signal, whi...

-

Safety features such as emergency stop buttons, overload protection, and safety guards are integral parts of a compression testing machine to ensure operator sa...

-

Modern compression testing machines are equipped with advanced software and data acquisition systems for real-time data recording, analysis, and report generati...

-

The platens are flat, parallel plates mounted on the load frame and come in various sizes to accommodate different block specimen dimensions. They provide the i...

-

Strain gauges or extensometers are used to measure the deformation or strain experienced by the block specimen during compression testing. This data is essentia...

-

Regular calibration is essential for maintaining the accuracy and reliability of a compression testing machine. Calibration equipment, including calibration wei...

-

.jpg)

The entry point for adding cement to the silo, often equipped with an airtight seal to prevent air and moisture from entering the storage area....

-

Essential for maintenance and inspection, providing a safe and convenient way for personnel to access the top and sides of the silo....

-

Installed on the walls of the silo to prevent material buildup or clogging, ensuring consistent flow and discharge of cement....

.jpg)

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China