QT5-15 Block Production Line Successfully Running in Madagascar with Full Technical Support

Hawen Machinery is proud to announce that the QT5-15 block production line in Madagascar has successfully commenced production, equipping the client with a versatile and high-efficiency solution for hollow blocks, U-shaped blocks, pavers, and curb stones. This milestone underscores Hawen’s commitment to providing complete technical support and ensuring optimal performance from day one.

Installation and Commissioning

Following shipment, Hawen dispatched experienced engineers from our East Africa service center to Madagascar to supervise the installation and commissioning. Over a ten-day installation period, the technical team guided the client through every critical step:

Equipment Placement: Main forming machine and auxiliary equipment were positioned precisely according to the client’s foundation layout.

Electrical and Hydraulic Connections: Engineers supervised all wiring and hydraulic piping to ensure safe and stable operation.

Dry Run Testing: The machine was operated without material to verify motion sequences, vibration performance, and hydraulic reliability.

Trial Production: Moulds were installed and tested with actual concrete material. Each product type—hollow blocks, U-shaped blocks, pavers, and curb stones—was trialed individually to confirm proper compaction, accurate block dimensions, and efficient demoulding.

Operator Training

After installation, Hawen engineers conducted 18 days of comprehensive on-site training for the client's operators, covering:

Safe operation of the QT5-15 main forming machine and JS500 twin-shaft concrete mixer

Accurate batching and proportioning of raw materials to ensure consistent block quality

Step-by-step mould change procedures for hollow blocks, U-shaped blocks, pavers, and curb stones

Proper use of GMT pallets for block handling and demoulding

Routine maintenance and troubleshooting for long-term reliability

This training ensures the client's team can independently operate the full production line while maintaining high-quality output and stable production efficiency.

HAWEN Mould Sets and Specifications

The production line is supplied with 13 sets of versatile moulds, allowing the client to produce a wide variety of construction blocks:

Hollow Blocks:

400 × 100 × 200 mm

400 × 150 × 200 mm

400 × 200 × 200 mm

500 × 200 × 200 mm

Operator Training

After installation, Hawen engineers conducted 18 days of comprehensive on-site training for the client's operators, covering:

Safe operation of the QT5-15 main forming machine and JS500 twin-shaft concrete mixer

Accurate batching and proportioning of raw materials to ensure consistent block quality

Step-by-step mould change procedures for hollow blocks, U-shaped blocks, pavers, and curb stones

Proper use of GMT pallets for block handling and demoulding

Routine maintenance and troubleshooting for long-term reliability

This training ensures the client's team can independently operate the full production line while maintaining high-quality output and stable production efficiency.

HAWEN Mould Sets and Specifications

The production line is supplied with 13 sets of versatile moulds, allowing the client to produce a wide variety of construction blocks:

Hollow Blocks:

400 × 100 × 200 mm

400 × 150 × 200 mm

400 × 200 × 200 mm

500 × 200 × 200 mm

500 × 150 × 200 mm

Interlocking Block:

518 × 200 × 200 mm

U-Shaped Block:

400 × 200 × 200 mm

Pavers:

Interlocking Paver:

225 × 112.5 × 60 mm

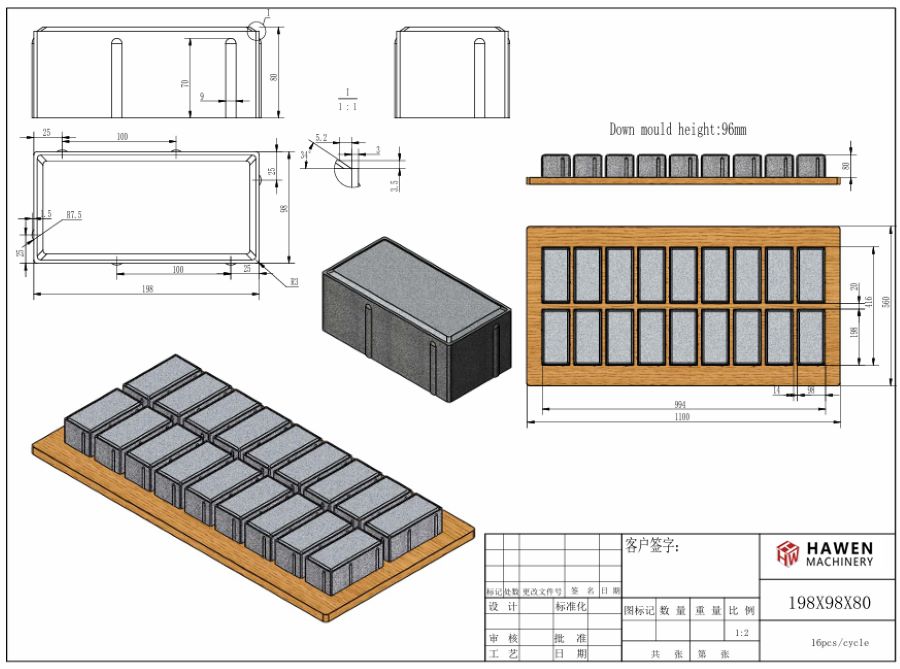

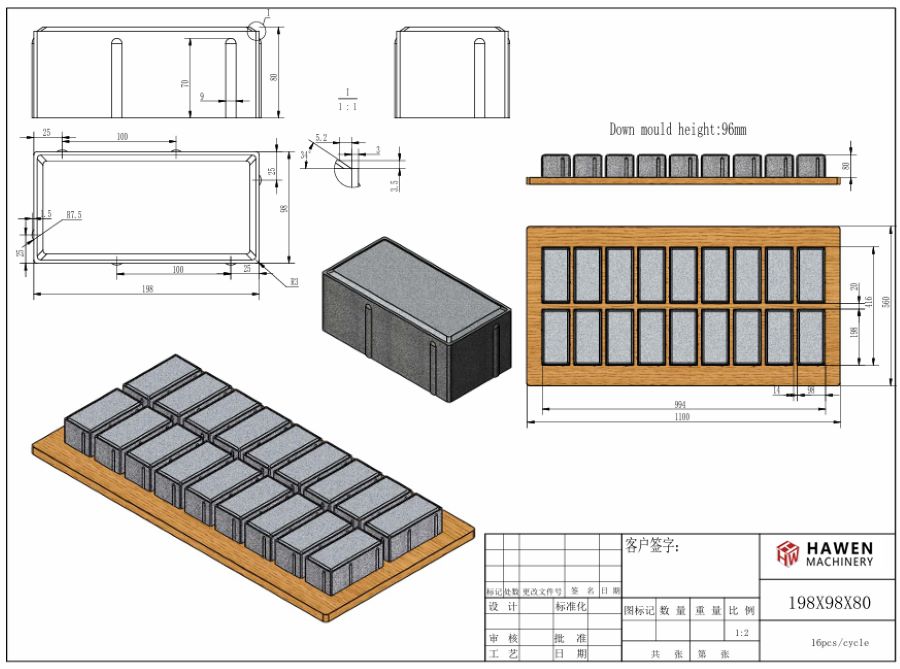

Rectangle Paver:

198 × 98 × 80 mm

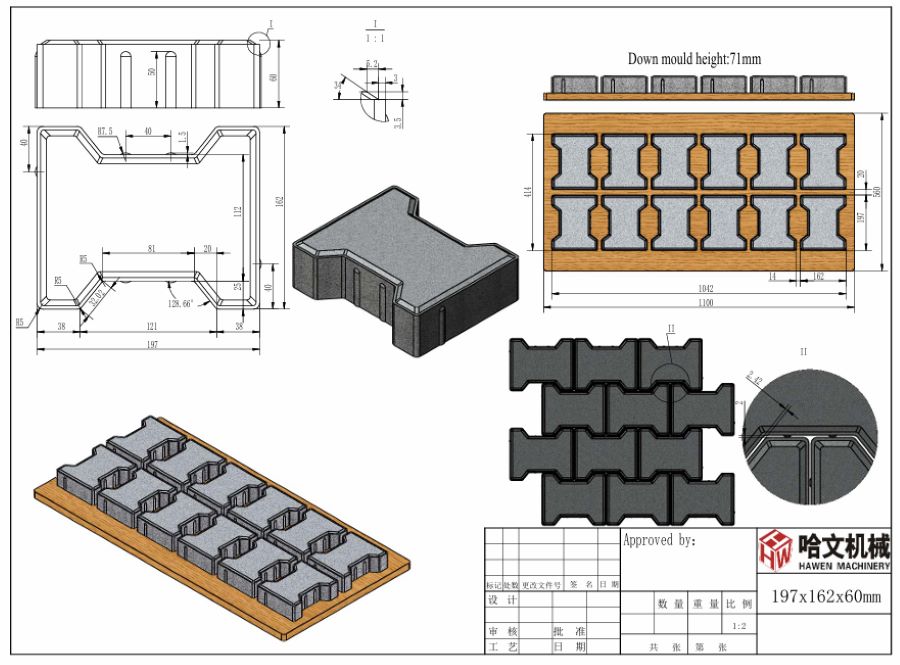

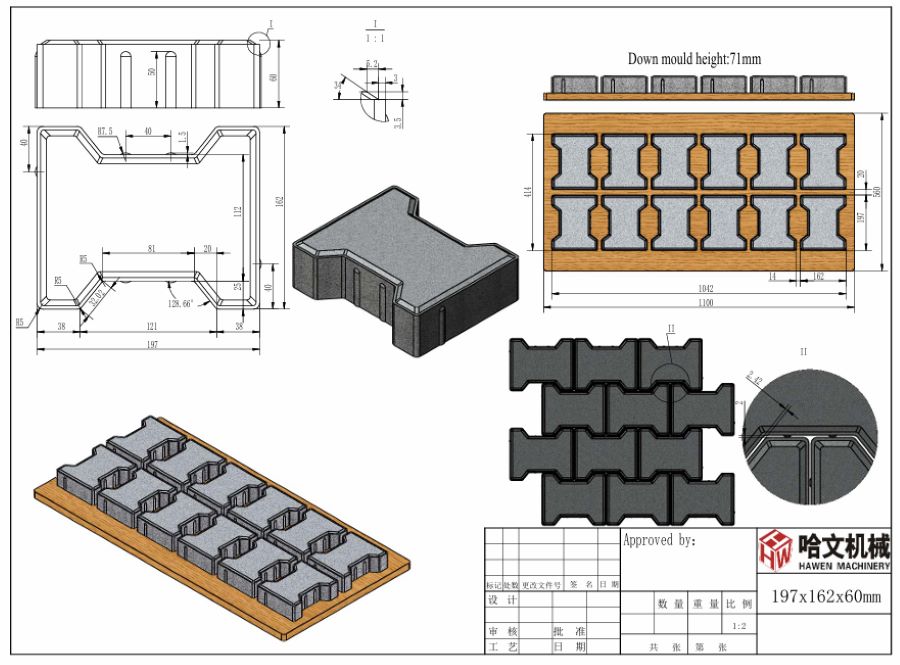

I-Shape Block: 197 × 162 × 60 mm

Curb Stones:

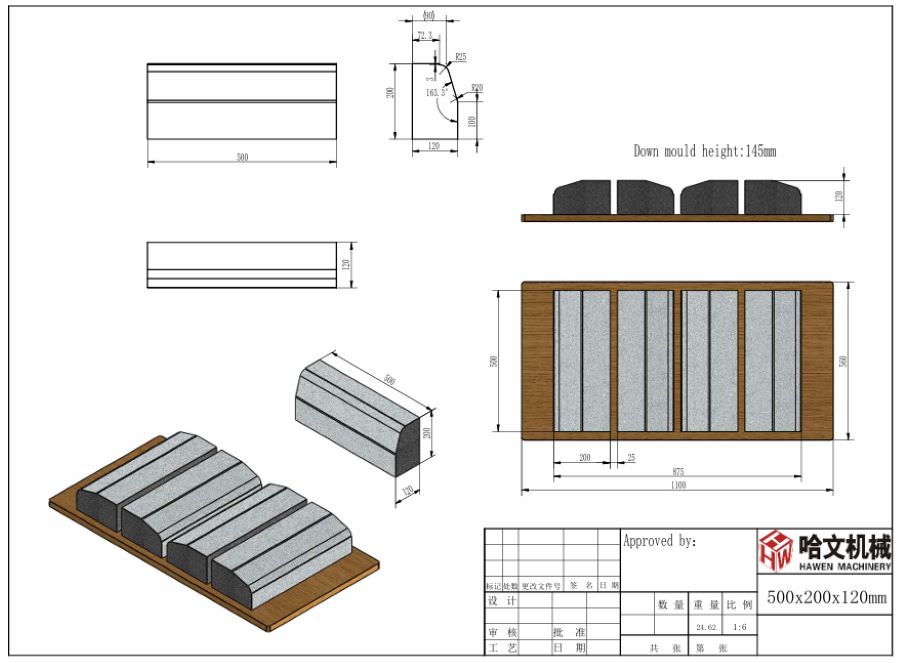

Curb Stones:

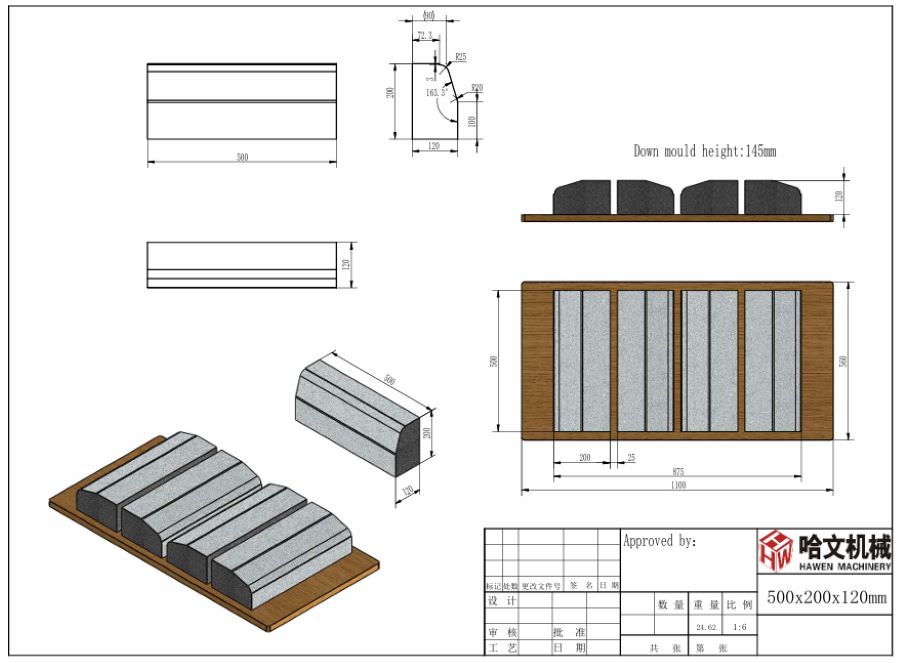

500 × 200 × 120 mm

1000 × 200 × 120 mm

All moulds are manufactured from high-quality alloy steel, manganese steel, or hardened carbon steel to ensure durability and consistent block quality. Quick-change mould systems allow smooth transitions between products.

Key Technical Highlights

Mechanical System:

Heavy-duty welded steel frame for stability under continuous operation

High-precision guides and wear-resistant components minimize mechanical errors

Quick-change mould system enables smooth transitions between block types

Hydraulic System:

High-performance system with Japanese YUKEN valves ensures smooth, shock-free operation

Designed for reduced downtime and extended service life

Electrical & PLC System:

Siemens PLC with touch-screen HMI interface for intuitive operation

1000 × 200 × 120 mm

All moulds are manufactured from high-quality alloy steel, manganese steel, or hardened carbon steel to ensure durability and consistent block quality. Quick-change mould systems allow smooth transitions between products.

Key Technical Highlights

Mechanical System:

Heavy-duty welded steel frame for stability under continuous operation

High-precision guides and wear-resistant components minimize mechanical errors

Quick-change mould system enables smooth transitions between block types

Hydraulic System:

High-performance system with Japanese YUKEN valves ensures smooth, shock-free operation

Designed for reduced downtime and extended service life

Electrical & PLC System:

Siemens PLC with touch-screen HMI interface for intuitive operation

Supports automated production cycles, fault detection, and precise synchronization of hydraulic and vibration systems

Concrete Mixer – JS500 Twin-Shaft:

Delivers uniform, high-quality concrete for all block types

Supports both bottom and surface material feeding

Heavy-duty wear-resistant blades extend service life and reduce maintenance

GMT Pallets:

Durable and recyclable, ensuring precise block dimensions and reducing breakage

Automatic Block Stacker & Pallet Provider:

Efficient stacking and continuous pallet supply for uninterrupted production

Client Benefits and Hawen Support

The Madagascar client selected Hawen Machinery for:

Proven reliability and performance of the QT5-15 production line

Complete production package, including concrete mixer, GMT pallets, and versatile HAWEN moulds

Thorough pre-shipment testing ensuring stable operation upon arrival

Flexible and multi-brand compatible moulds

Full technical support from East Africa-based engineers, including installation, commissioning, and operator training

Long-term investment value with durable equipment, high-quality spare parts, and responsive service

With Hawen's on-site block machine installation and training, the client now produces hollow blocks, U-shaped blocks, pavers, and curb stones efficiently and consistently, maximizing productivity and product quality.

Conclusion

The successful commissioning and operation of the QT5-15 block production line in Madagascar demonstrates Hawen Machinery's ability to deliver complete, high-performance block manufacturing solutions. Thanks to Hawen's advanced QT5-15 block production line and full set of supporting equipment, the client is now capable of producing multiple block types with unmatched consistency and high quality, including hollow blocks, U-shaped blocks, and pavers. The reliability and flexibility of the equipment enable the client to quickly establish a leading position in the local market, improving production efficiency while minimizing operational risks. With precise control over raw material proportions and rapid mold changes, the client can fulfill more diverse orders, enhance product value, and strengthen market competitiveness. Equipped with Hawen’s technical support and comprehensive production system, the client is not only solidifying their leadership locally but also laying a strong foundation for future regional and even international market expansion.

Hawen Machinery – Your trusted partner for turnkey block production solutions and full technical support in Africa and worldwide.

Conclusion

The successful commissioning and operation of the QT5-15 block production line in Madagascar demonstrates Hawen Machinery's ability to deliver complete, high-performance block manufacturing solutions. Thanks to Hawen's advanced QT5-15 block production line and full set of supporting equipment, the client is now capable of producing multiple block types with unmatched consistency and high quality, including hollow blocks, U-shaped blocks, and pavers. The reliability and flexibility of the equipment enable the client to quickly establish a leading position in the local market, improving production efficiency while minimizing operational risks. With precise control over raw material proportions and rapid mold changes, the client can fulfill more diverse orders, enhance product value, and strengthen market competitiveness. Equipped with Hawen’s technical support and comprehensive production system, the client is not only solidifying their leadership locally but also laying a strong foundation for future regional and even international market expansion.

Hawen Machinery – Your trusted partner for turnkey block production solutions and full technical support in Africa and worldwide.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China