Double QT12 Automatic block making plant successful running in Egypt

In late October 2025, two complete QT12-15 Automatic Block Making Production Lines were officially put into operation in Rafah,Egypt. This landmark project was delivered in partnership with Organi Group, a highly respected construction materials manufacturer with strong local influence and decades of industry experience.

*Renowned for their strong industrial experience and strategic vision, Organi Group focuses on high-quality paving bricks, hollow blocks, and commercial concrete products that support Egypt’s rapidly expanding infrastructure sector.

Egypt’s construction market is growing faster than ever, and Organi Group stands at the forefront of this progress. As an influential developer and manufacturer of building materials, Organi Group is committed to delivering high-quality paving solutions and structural blocks for infrastructure and urban development projects across the country.

To strengthen their production capability and meet rising demand, Organi Group invested in two HAWEN QT12-15 full-automatic block production lines. Today, both lines are up and running successfully, delivering outstanding performance and premium concrete block products to the Egyptian market.

QT12-15 production line

*Powerful Production Configuration

1.Advanced Batching & Mixing System

For stable and high-efficiency concrete preparation, the plant is equipped with a fully automated batching and mixing configuration:

• PL1600-III Aggregate Batching Machine (Three Bins):

Capable of handling multiple granular materials with precise weighing accuracy, ensuring consistent block density and strength.

PL1600-III with three bin

• PL800-I Face Material Batching Machine (Single Bin):

Specially used for producing high-quality surface layers on pavers, improving product wear resistance and appearance.

PL800-I with single bin

• 1000L Planetary Mixer for Bottom Material:

Provides powerful mixing performance with uniform concrete distribution, ideal for manufacturing durable hollow blocks with strong load-bearing capacity.

Planetary mixer

• 330L Planetary Mixer for Face Material:

Delivers refined, high-consistency face mixes that create smooth and attractive surfaces for rectangle pavers.

2.QT12-15 Main Forming Machines

Two main machines operate with high efficiency and molding accuracy. They deliver strong block density thanks to our advanced hydraulic pressure system, allowing uniform vibration energy distribution and excellent compaction results.

QT12-15 forming system

2.1 Hydraulic System

The QT12-15 production line features an advanced hydraulic system powered by Japanese Yuken proportional valves. Operators can fine-tune flow and pressure directly through the Siemens HMI interface, keeping every motion smooth, precise, and impact-free.

The dual-vane pump design enables multiple coordinated actions at once, dramatically boosting throughput.

The hydraulic power unit includes a high-performance ALBERT hydraulic pump from the USA, delivering stable pressure, quiet operation, and exceptional durability for round-the-clock production.

2.2 Industrial Oil Cooling System

A dedicated industrial oil cooler continuously regulates hydraulic oil temperature during high-intensity operation. This ensures consistent system stability, prevents heat-related failures, and prolongs the lifespan of all hydraulic components.

2.3 Intelligent Electrical Control System

Equipped with a Siemens PLC, touch screen interface, and German-style automation logic, the system delivers accurate motion control and rapid diagnostics.

Easy operation, low maintenance frequency, and intelligent alarms enhance production reliability with minimum downtime.

2.4 High-Efficiency Vibration System

The machine utilizes a combination of dynamic vibration and static pressing, creating optimal compaction from the core to the surface.

This technology ensures hollow blocks are strong and uniform while rectangle pavers achieve excellent density, edge sharpness, and long-term durability.

3.Automatic Stacker System

The Automatic Stacker System plays a crucial role in the dry-side operation. It automatically stacks cured blocks and pavers from pallets onto the production yard or transport area. This system replaces manual labor with an efficient robotic process, ensuring speed, accuracy, and product consistency.

This complete system ensures every block produced meets Organi Group’s standards for strength, precision, and long-service performance, while maintaining a steady production rhythm even during peak demand.

*Local Production Bricks Using This Equipment

The following bricks and pavers are produced locally in Egypt using the QT12-15 production lines:

1.Solid Brick Mould (250×60×120 mm, 54 pcs/mould)

Specifically engineered to produce compact and durable bricks with smooth surfaces, ideal for construction applications where strength and consistency are critical.

Solid Brick

2.Solid Block Mould (400×150×200 mm, 12 pcs/mould)

Designed for heavy-duty structural blocks, this mould ensures high load-bearing capacity, making it perfect for wall construction and foundation projects.

3.Hollow Block Mould (400×150×200 mm, 16 pcs/mould and 400×120×200 mm, 20 pcs/mould)

Enables the production of lightweight yet strong hollow blocks, offering excellent insulation and reduced material usage while maintaining structural integrity for residential and commercial buildings.

Hollow block

Hollow blocks

4.Uni Paver Mould (240×120×60 mm, 30 pcs/mould)

Creates uniform, resilient pavers suitable for driveways, walkways, and patios, combining durability with precise dimensions for easy installation.

5.Hexagonal Paver Mould (228×197×60 mm, 26 pcs/mould)

Produces interlocking hexagonal pavers with a visually striking design, perfect for decorative and functional landscaping projects.

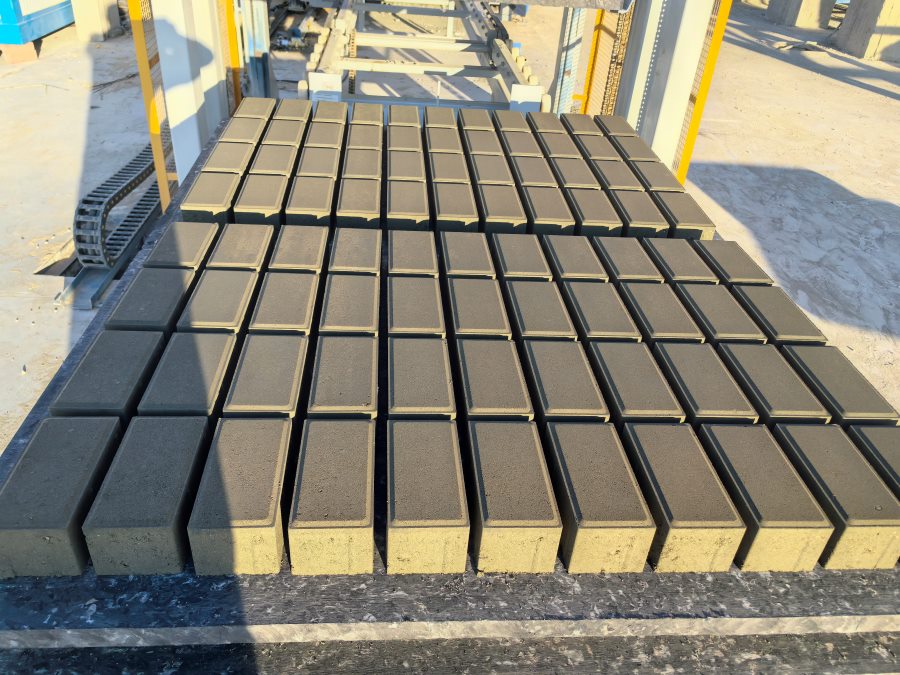

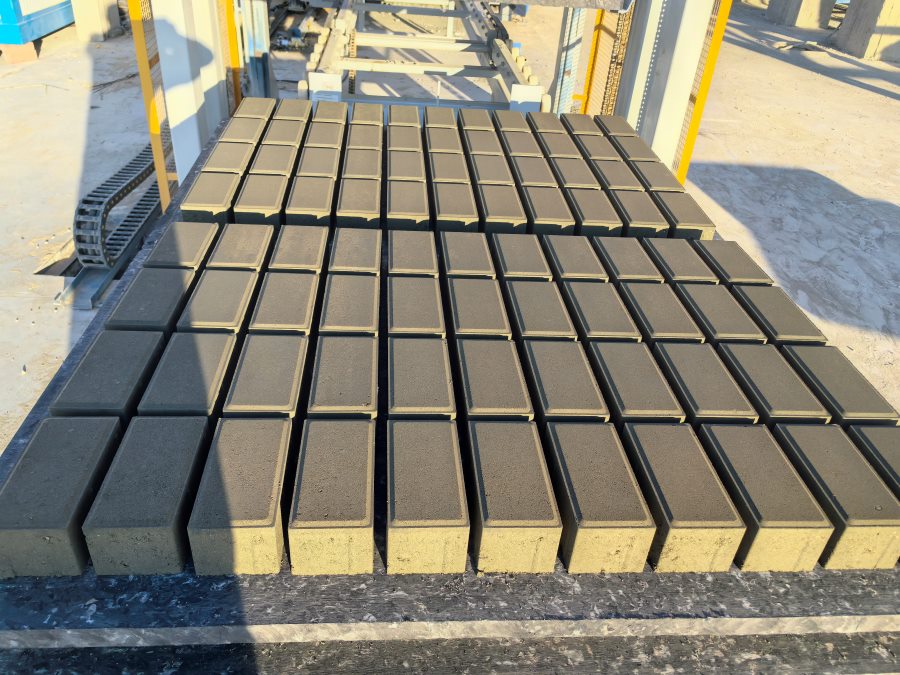

6.Rectangular Paver Mould (200×100×60 mm, 44 pcs/mould and 200×100×80 mm, 44 pcs/mould)

Ideal for strong, visually appealing rectangular pavers, providing a smooth finish and high durability for pedestrian paths and outdoor surfaces.

Rectangle paver

7.Behaton Paver Mould (198×163×60 mm, 30 pcs/mould)

Designed to manufacture interlocking Behaton pavers, delivering high load-bearing strength for heavy-traffic areas while maintaining precise alignment and long-lasting performance.

*A Partnership Built on Trust and Technology

Organi Group evaluated many global machinery manufacturers before making their decision. Through detailed technical comparisons, professional factory audits, and multiple rounds of in-depth communication, Organi Group selected HAWEN Machinery with strong confidence. Their decision was shaped by the following key factors:

• Strong industrial reputation and engineering expertise

HAWEN Machinery has a proven track record of delivering advanced block production solutions worldwide, supported by a professional R&D and manufacturing team with deep industry experience.

• Reliable automation and intelligent control systems

The seamless integration of PLC control, servo vibration, and fully automatic handling systems ensures high productivity, stable operation, and reduced manpower, meeting modern industrial standards for intelligent manufacturing.

• High-quality components ensuring durability and long-term stability

From the hydraulic system to vibration units and wear-resistant structures, all critical parts are made with premium materials and undergo strict quality testing. This guarantees long service life, lower maintenance cost, and consistent block quality throughout production.

They expressed strong confidence in HAWEN Machinery’s advanced manufacturing capabilities after visiting our factory.This reinforced their trust in the quality and reliability of our equipment, laying a solid foundation for long-term cooperation.

*Strong Results for Market Success

Both production lines are running smoothly and efficiently. The results speak for themselves:

✔ High daily output to meet booming market demand

✔ Stable production with minimal downtime

✔ Strong, durable, and aesthetically pleasing paving bricks

✔ Significant reduction in labor through full automation

✔ Streamlined storage and logistics system

QT12-15 block making machine

*Organi Group is now well-positioned to stay ahead in the market, delivering high-performance building materials that support Egypt’s fast-moving construction landscape. Every hollow block and every paver rolling off their double QT12-15 lines represents efficiency, precision, and confidence in the future.

*HAWEN Machinery × Organi Group

A partnership powered by engineering innovation and shared ambition.

What begins as machinery becomes a foundation for cities.

Quality inspires trust.

Technology enables progress.

Collaboration creates the future.

Together, we build stronger.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China