HAWEN QT12-15 Automatic Block Making Plant Successful Running in Vietnam.

In the first week of August 2025, HAWEN QT12-15 Automatic Block Making Plant successful running in Vietnam.It is now in full production, manufacturing hollow blocks, solid bricks, and two-hole bricks to meet the growing demand for local infrastructure and housing projects.

To ensure a smooth start-up, HAWEN MACHINERY dispatched experienced technical engineers to the site for installation supervision, commissioning, and operator training.

Our team worked closely with the client to optimize the production line layout, calibrate the system, and provide hands-on guidance — ensuring the plant reached stable mass production quickly and efficiently.

✅ Customer Background & Decision Process

To meet the rising demand for high-quality construction blocks in the Vietnamese market, the client sought a fully automated, high-capacity solution to replace outdated semi-manual equipment. After comparing several international suppliers, the client chose HAWEN MACHINERY.

*Evaluation criteria included:

1.Machine performance and output capacity

2.Hydraulic and control systems

3.Component quality and durability

4.After-sales service responsiveness

5.Price-to-performance ratio

6.Factory strength and technical support capability

✅ After in-depth technical communication, factory inspections, and case reviews of previous HAWEN projects, the client was confident that HAWEN MACHINERY offered the best combination of quality, service, and value.

The final decision to choose HAWEN QT12-15 block making machine was made based on trust in the brand, proven references, and the ability to customize a solution tailored to their needs.

✅ Full Production Line Configuration

The Vietnam project was delivered as a complete automatic block production line, designed and supplied entirely by HAWEN MACHINERY, including:

1.Batching and Mixing System – for automatic proportioning and uniform mixing of cement, sand, and aggregates

*PL1600 Three-Hopper Batching Machine

This model features three independent aggregate storage bins, with automatic weighing and batching for sand, gravel, and crushed stone.

The system delivers high batching accuracy and smooth material flow, supporting stable block quality over long production runs.

*MP1000 Planetary Concrete Mixer

A high-performance planetary-type mixer designed for concrete block production, offering excellent mixing homogeneity, short mixing time, and low maintenance.

The planetary mixing action ensures even distribution of cement, water, and aggregates, resulting in superior block strength and surface finish.

2.Automatic Pallet Provider – ensures continuous and accurate pallet supply to the forming machine

3.QT12-15 Main Forming Machine – for high-speed, high-precision molding of various concrete blocks,with automatic mould-quick-changing device,Pallet size at 1400x950mm.

4.Automatic Block Stacker – for efficient stacking and space-saving transfer

This integrated system delivers not only high production output, but also significant savings in labor and operating costs.

✅ Block Types Produced by QT12-15 Block Making Machine

The HAWEN QT12-15 Automatic Block Making Machine is highly versatile and capable of producing a wide range of concrete products. In this Vietnam project, the machine is configured to manufacture the following three main types of blocks:

1.Hollow Blocks

*Size: 390 × 120 × 180 mm

*Output: 20 pieces per mould

*Application: Exterior and load-bearing walls in construction

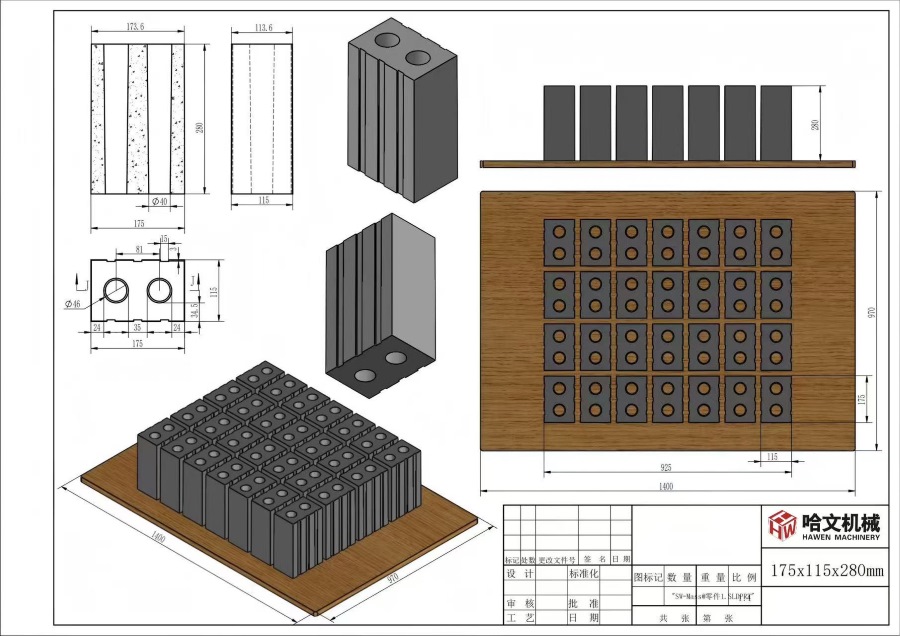

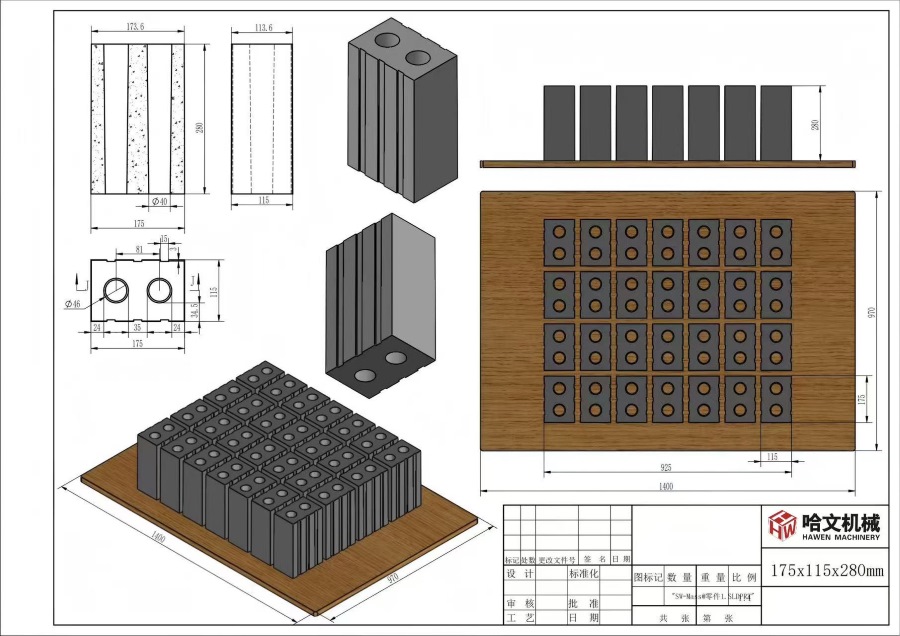

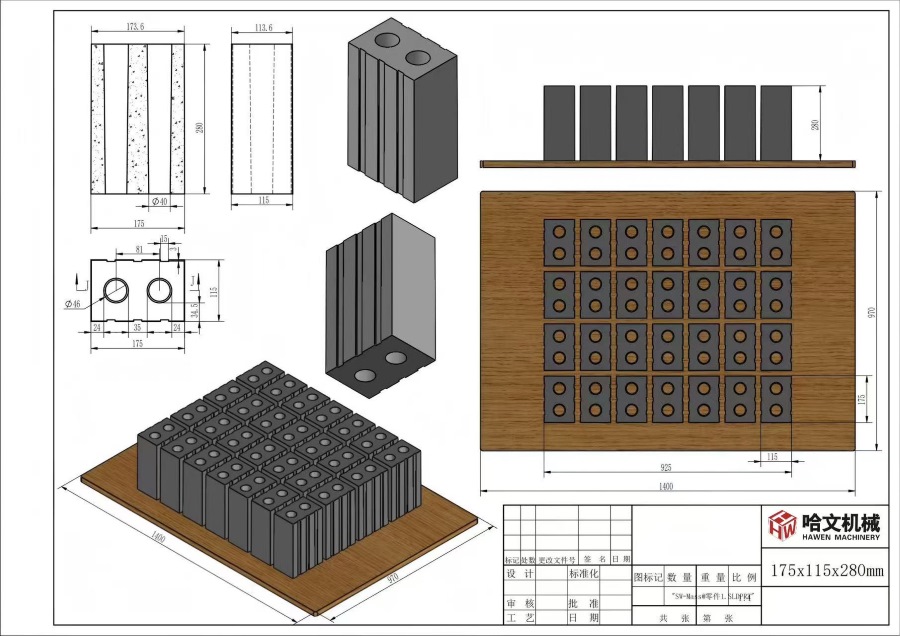

2.Two-Hole Bricks

*Size: 175 × 115 × 280 mm

*Output: 28 pieces per mould

*Application: Ventilated partition walls and economical housing projects

3.Solid Bricks

*Size: 218 × 58 × 103 mm

*Output: 76 pieces per mould

*Application: Internal partition walls and paving base layers

These products can be switched flexibly thanks to the quick mould changing system, allowing the customer to respond to different market demands efficiently.

✅ Why the Customer Chose HAWEN QT12-15 Block Making Machine

The QT12-15 block making machine is one of HAWEN’s flagship models, designed for industrial-scale concrete block production. Its robust mechanical structure, intelligent automation, and modular system make it a reliable solution for manufacturers aiming to scale efficiently and maintain consistent product quality. It is particularly suited for markets where both output and flexibility are essential.

1.Efficient and Flexible Production Performance

The QT12-15 block making machine impressed the client with its ability to produce multiple block types — including 20 hollow blocks per cycle, two-hole bricks, and 76 solid bricks per mould — all on a single production line. With the automatic quick-mould changing system, the plant adapts quickly to different orders, helping the customer serve both infrastructure and residential construction projects efficiently.

2.Advanced Control and Automation

Equipped with a SIEMENS PLC control system and touch screen interface, the QT12-15 block making machine offers stable performance, intelligent fault diagnostics, and easy operation for workers. The client particularly appreciated the remote monitoring and upgrade capabilities, which ensure smoother daily management and lower downtime.

3.Reliable Hydraulic and Mechanical Systems

The machine’s dual high-pressure hydraulic system with proportional control delivers strong and consistent pressing force, ensuring excellent block density and strength. Combined with heavy-duty mechanical structure and precision vibration platform, the system ensures long-term stability even under high production volumes.

4.Professional Technical Support and Trustworthy Service

Throughout the procurement process, HAWEN provided clear technical drawings, video demonstrations, and detailed plant layout proposals tailored to the customer’s site. This professional approach — along with fast communication and transparent pricing — gave the client confidence that they were choosing a reliable long-term partner.

✅ HAWEN Machinery in Vietnam

The successful installation and smooth operation of the QT12-15 block making machine in Vietnam is one of many examples of HAWEN MACHINERY’s growing presence in Southeast Asia.

From equipment supply to on-site guidance, and from mold customization to after-sales support, HAWEN continues to build long-term partnerships with concrete producers across Vietnam — empowering them with efficient, reliable, and scalable production solutions.

As the demand for modern infrastructure and urban development in Vietnam increases, HAWEN MACHINERY is proud to contribute advanced technology and dependable service to support the country’s concrete product industry.

This project once again proves that HAWEN MACHINERY is not only a machine supplier, but a trusted partner in building the future of concrete production.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China