On the third week of May 2025, there are two sets of HAWEN QT12-15 Block Making Plant has been shipped to a valued client in Egypt. This delivery marks another milestone in expanding our presence in the Middle Eastern and North African region and reaffirms our commitment to providing high-performance block machine solutions globally.

The shipment covers Two sets of QT12-15 Automatic block making plant with automatic batching and mixing system, 3000pcs of GMT Pallet and 16 sets of quality concrete block and interlocking paver mould and solid brick mould.

The HAWEN QT12-15 block making machine with the pallet size at 1400x950mm,it is well known for its high efficiency, durability, and automation capabilities, making it an ideal solution for large-scale production of concrete blocks.

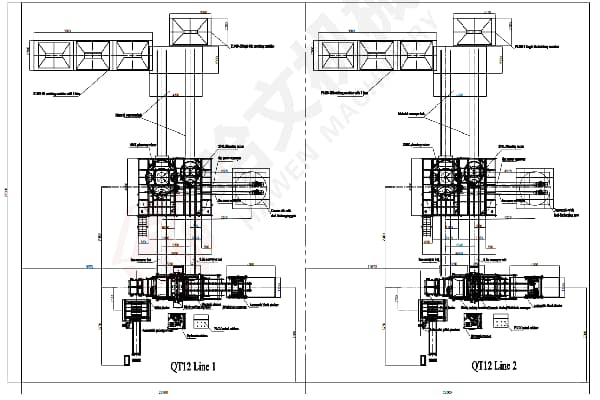

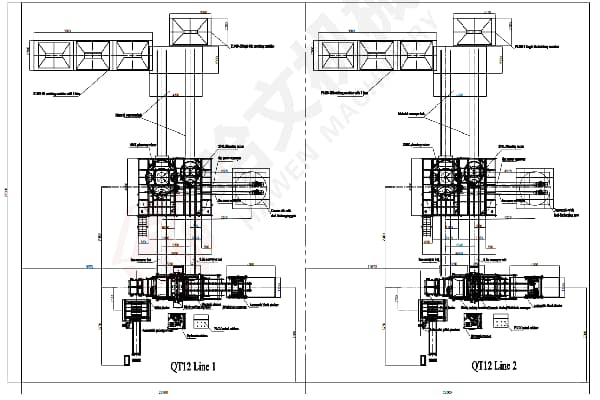

Layout Drawing for Plant:

To ensure a smooth installation and efficient workflow, we have provided a detailed layout drawing for the plant, customized according to the client’s site plan. This drawing includes the positioning of:

Block machine and Automatic block stacker;

Batching and mixing system;

Conveyor belts and Pallets feeding system;

Cement silos ;

Control room and maintenance access zones;

This layout supports optimal space utilization and production efficiency.

Hot Testing Before Shipment:

After the fabrication of equipment is ready, the QT12-15 block machine underwent rigorous hot testing to make hollow block,solid brick and interlocking paver at our factory. The machine was fully assembled and operated with materials to simulate real production conditions. All mechanical, electrical, and hydraulic systems were tested for stability, precision, and output performance—ensuring the machine is factory-certified and ready for immediate use.

Hollow block mould 400x150x200mm at 16pcs/mould in QT12-15 block making machine :

Solid brick at 250x60x120mm at 54pcs/mould in QT12-15 brick making machine

240x120x60mm interlocking paver at 30pcs/mould made by QT12-15 brick making machine

Batching and Mixing System:

The supplied batching and mixing system is engineered to provide consistent and high-quality concrete mix for block production. It includes:

Automated weighing and batching machine,for the bottom material, it adopts PL1600-III Batching machine with three bins, for the facing material,it adopts PL800-I Concrete batching machine.

High-efficiency planetary concrete mixer,the mixer for bottom material adopts 1000L Planetary mixer, while for the facing material,adopts 330L planetary mixer.

Automatic batching and mixing control system, with PLC control,allows the plant to work automatically with labor free.

This system ensures accurate mix proportions and continuous supply to the block machine, enhancing production output and quality.

Advantages of HAWEN Block Machine:

The HAWEN QT12-15 model is one of the most advanced block production systems in the market. Its key advantages include:

High Output Capacity:to produce Egyptian standard solid brick at 250x60x120mm,it can make up to 100,000pcs per shift at 8 hours.

Siemens PLC Automation: Ensures smart, user-friendly operation

Durable Steel Frame: Built for longevity and heavy-duty use

Advanced Vibration System:with 2 sets of 15KW vibration motor,4-shafts vibrtion box,delivers high-density, uniform concrete blocks

Energy Efficient Design: Reduces operating costs and improves sustainability

These features make it the ideal choice for large-scale block production projects in Egypt and other developing markets.

Aftersales Service Support in Egypt

HAWEN Machinery provides comprehensive aftersales service support in Egypt, which includes:

On-site installation and commissioning assistance;

Operator and maintenance personnel training;

24/7 technical support via remote communication;

Fast delivery of spare parts and consumables from local service partners;

Our dedicated support team ensures that our Egyptian clients achieve maximum machine uptime and long-term productivity.

Our technical support team is coordinating with the client to provide on-site installation guidance, operational training, and after-sales service. This ensures that the machine will be fully operational upon arrival, contributing to immediate project deployment.

Hawen machinery have successful in cooperating with many clients in Egypt before,such as the valued client “Hassan Allam holding”, “Concrete Plus Ltd”,the plants provided by Hawen machinery has been successful running for these customer for many years.

The New shipment of the HAWEN QT12-15 Block Making Plant to our new client in Egypt further strengthens our global reach and our commitment to delivering top-tier construction machinery backed by expert service.

We are confident this installation will enhance the client’s production capacity and long-term success.

Welcome to contact our team for more detail information about the block making plant solutions.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China