QT10-15 Block Machine Successful Testing for Customer in Egypt

Project Overview

Two QT10-15 machines, configured with 1150 × 950 mm GMT pallets,underwent comprehensive pre-shipment testing to validate their operational stability, production efficiency, and product quality. The evaluation focused on the block making machine functionality, ensuring that the machines conform to technical specifications and are capable of continuous industrial operation under realistic production conditions. The testing also aimed to confirm the machines suitability for manufacturing both solid bricks and hollow blocks, providing reliable performance for high-volume construction projects.

Products Tested

During the testing, the QT10-15 block machine successfully produced both solid bricks and hollow blocks, demonstrating high precision, consistency, and adaptability in block production:

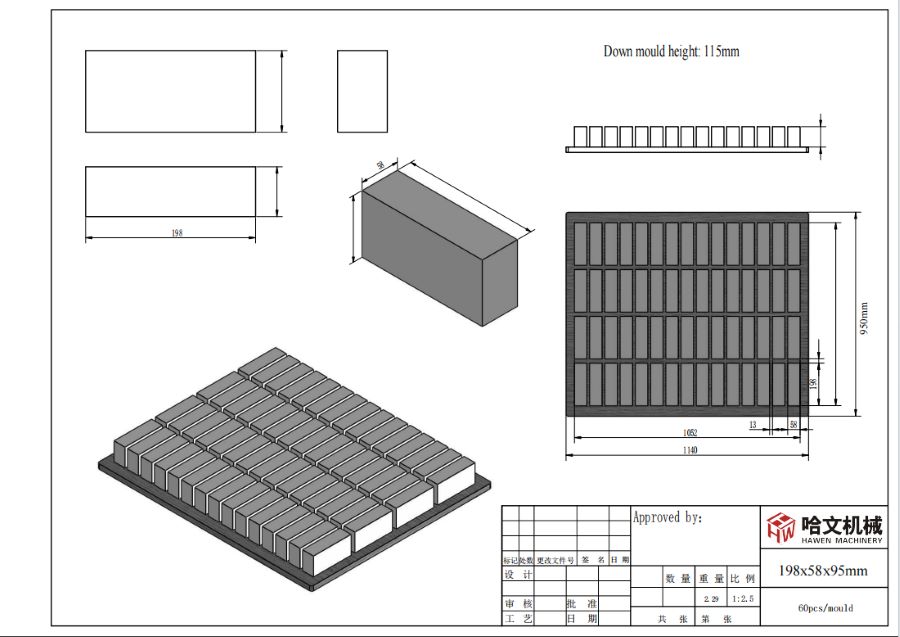

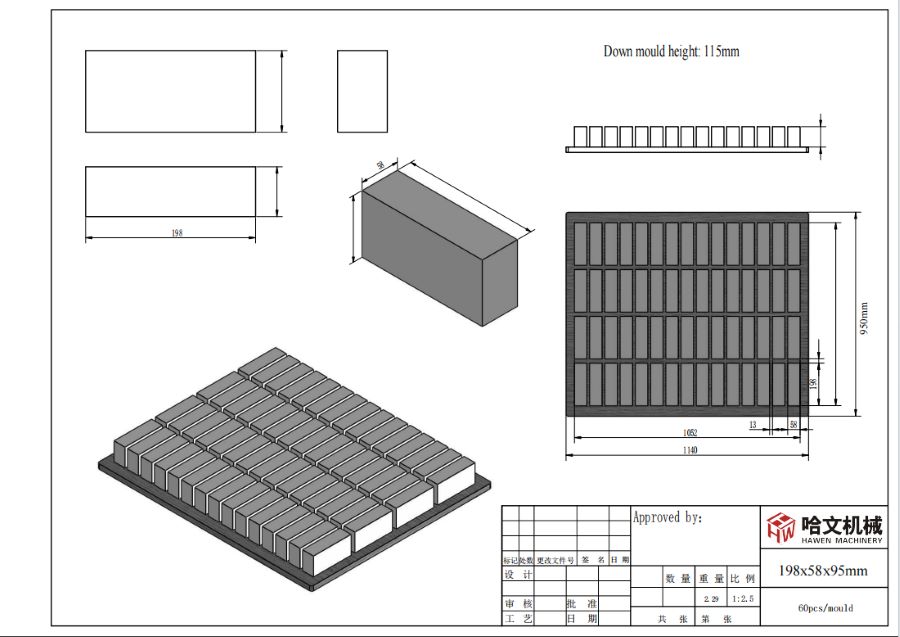

Solid Bricks

Dimensions: 198 × 58 × 95 mm

Output per mould: 60 pcs

Forming cycle time: 16 seconds

Pallet size: 1150 × 950 mm

Estimated output:13,500 pcs per hour,108,000 pcs per 8-hour shift

Observations:

Solid Bricks

Dimensions: 198 × 58 × 95 mm

Output per mould: 60 pcs

Forming cycle time: 16 seconds

Pallet size: 1150 × 950 mm

Estimated output:13,500 pcs per hour,108,000 pcs per 8-hour shift

Observations:

The solid bricks exhibited uniform density, consistent dimensions, smooth surfaces, and well-defined edges. Optimized compaction and vibration parameters ensured high structural integrity with minimal surface defects, suitable for demanding masonry applications.

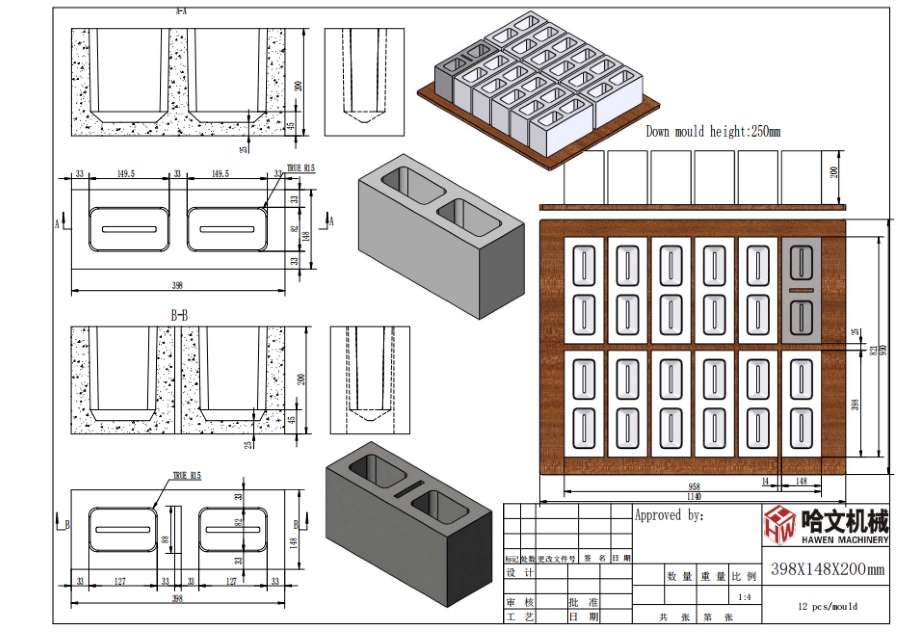

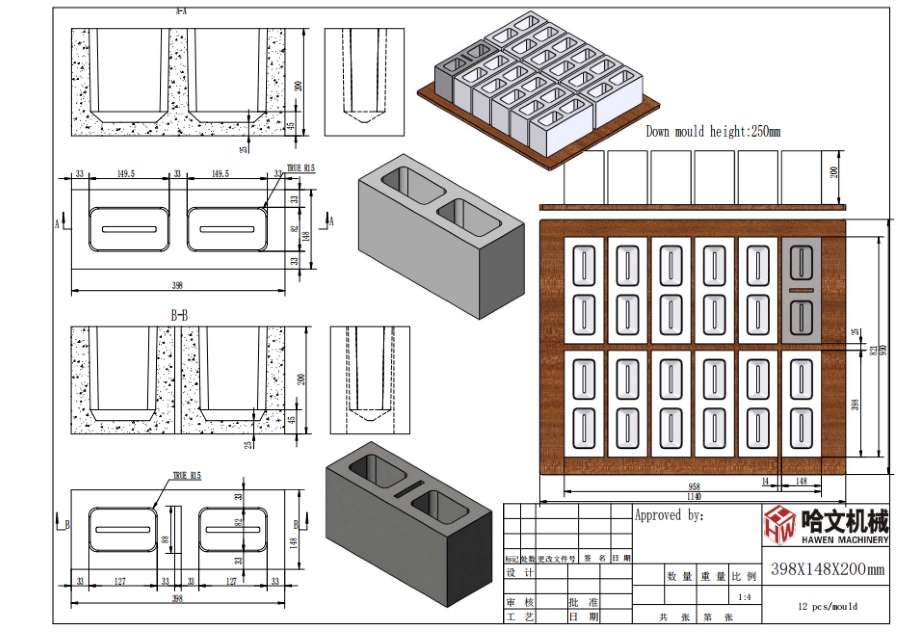

Hollow Blocks

Dimensions: 398 × 148 × 200 mm

Output per mould: 12 pcs

Forming cycle time: 19 seconds

Pallet size: 1150 × 950 mm

Estimated output:2100-2200pcs per hour

Observations:

The hollow blocks maintained consistent wall thickness, precise dimensions, and sharp edges. Block surfaces were smooth, with excellent structural stability, fully compliant with standard construction requirements.

Hollow Blocks

Dimensions: 398 × 148 × 200 mm

Output per mould: 12 pcs

Forming cycle time: 19 seconds

Pallet size: 1150 × 950 mm

Estimated output:2100-2200pcs per hour

Observations:

The hollow blocks maintained consistent wall thickness, precise dimensions, and sharp edges. Block surfaces were smooth, with excellent structural stability, fully compliant with standard construction requirements.

Test Run Conditions

Machines involved: two QT10-15 machines

Forming process: Controlled vibration combined with hydraulic compression, providing uniform compaction and high product density

Raw materials: Cement, sand, stone powder, and water, prepared according to manufacturer-recommended ratios to ensure consistent workability and strength

Power supply: Stable and continuous to simulate real production conditions

Test duration: Extended continuous operation to verify machine reliability under sustained workload

Operators: Skilled technicians monitored operation, ensuring that each production cycle met quality standards and cycle time specifications

Test Run Performance

The two QT10-15 machines operated continuously and reliably throughout the test period

Moulding and demoulding processes were smooth, with minimal surface defects and no sticking incidents, demonstrating precise control of vibration and hydraulic pressure

Finished products exhibited excellent dimensional consistency, structural integrity, and surface finish, suitable for both residential and commercial construction

Cycle times were consistent across all production batches, confirming the machines'efficiency and capability to maintain high output rates

Overall operational stability, including hydraulic pressure regulation, vibration control, and automatic mould release, was fully validated

Why Customers Choose HAWEN QT10-15 Block Making Machine

The QT10-15 block making machine offers multiple advantages that contribute to reliable, high-efficiency production:

Complete System Integration: Not merely a brick machine, but a full end-to-end concrete block production solution

Customized Configuration: Tailored plant layout and paver mould design for local market sizes and pallet standards

Advanced Mechanical & Hydraulic Design: Stable pressure, high vibration frequency, and lower defect rates

Local Technical Support: Engineers available to assist with installation, training, and maintenance

Durable GMT Pallets: Reinforced GMT pallets provide excellent rigidity, impact resistance, and weatherproof performance. They are reusable, recyclable, and long-lasting, effectively reducing operating costs

Test Run Conclusion

The pre-shipment testing confirmed that the two QT10-15 machines are fully capable of producing solid bricks and hollow blocks with repeatable high-quality standards and industrial-grade reliability. The block making machine ensures consistent production efficiency, precise dimensions, and structural integrity of all products. Both units are ready for shipment and on-site commissioning, providing reliable performance for large-scale construction projects and ensuring optimal productivity at the Egypt customer's facility.

Why Customers Choose HAWEN QT10-15 Block Making Machine

The QT10-15 block making machine offers multiple advantages that contribute to reliable, high-efficiency production:

Complete System Integration: Not merely a brick machine, but a full end-to-end concrete block production solution

Customized Configuration: Tailored plant layout and paver mould design for local market sizes and pallet standards

Advanced Mechanical & Hydraulic Design: Stable pressure, high vibration frequency, and lower defect rates

Local Technical Support: Engineers available to assist with installation, training, and maintenance

Durable GMT Pallets: Reinforced GMT pallets provide excellent rigidity, impact resistance, and weatherproof performance. They are reusable, recyclable, and long-lasting, effectively reducing operating costs

Test Run Conclusion

The pre-shipment testing confirmed that the two QT10-15 machines are fully capable of producing solid bricks and hollow blocks with repeatable high-quality standards and industrial-grade reliability. The block making machine ensures consistent production efficiency, precise dimensions, and structural integrity of all products. Both units are ready for shipment and on-site commissioning, providing reliable performance for large-scale construction projects and ensuring optimal productivity at the Egypt customer's facility.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China