Successful Shipment of GMT Pallets to Client in Congo

In the second week of July 2025, Hawen Machinery successfully shipped 1,000 pcs premium GMT pallets to a leading concrete product manufacturer in the Democratic Republic of Congo.

Our client, an established pallet specialist with an excellent local reputation, sought a durable pallet solution to support their expanding production of:

*High-quality paving stones

*Precision concrete blocks

*Architectural slabs

Facing demanding production requirements, the client conducted rigorous quality evaluations before ultimately selecting Hawen's GMT pallets. Key decision factors included:

✓ Superior load-bearing capacity

✓ Enhanced durability in tropical climates

✓ Precision-machined surface for perfect product finish

✓ Optimized heat transfer for faster curing cycles

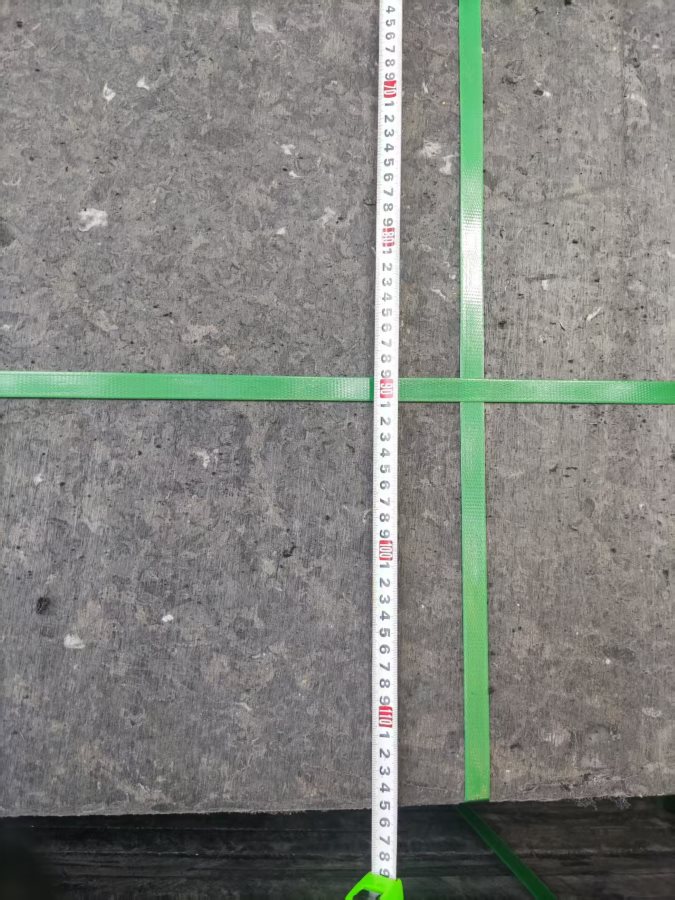

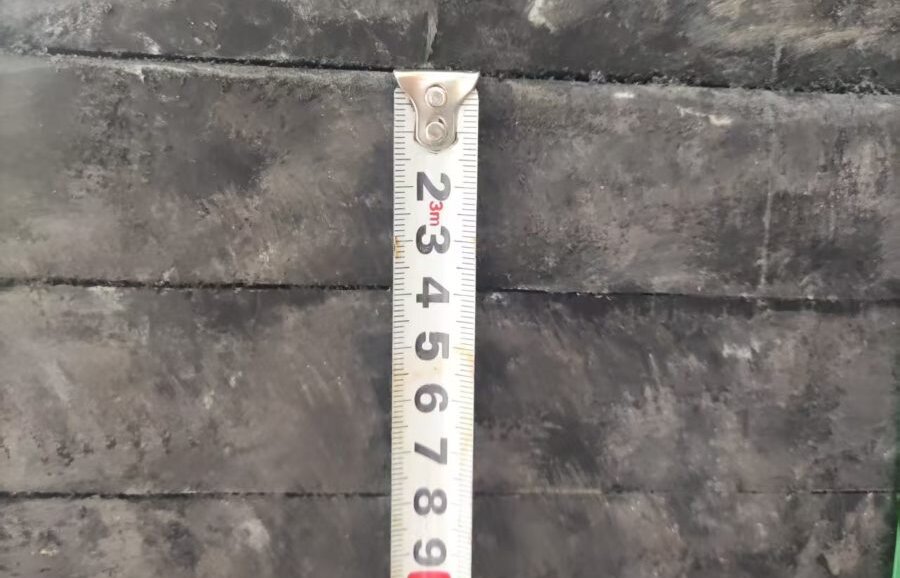

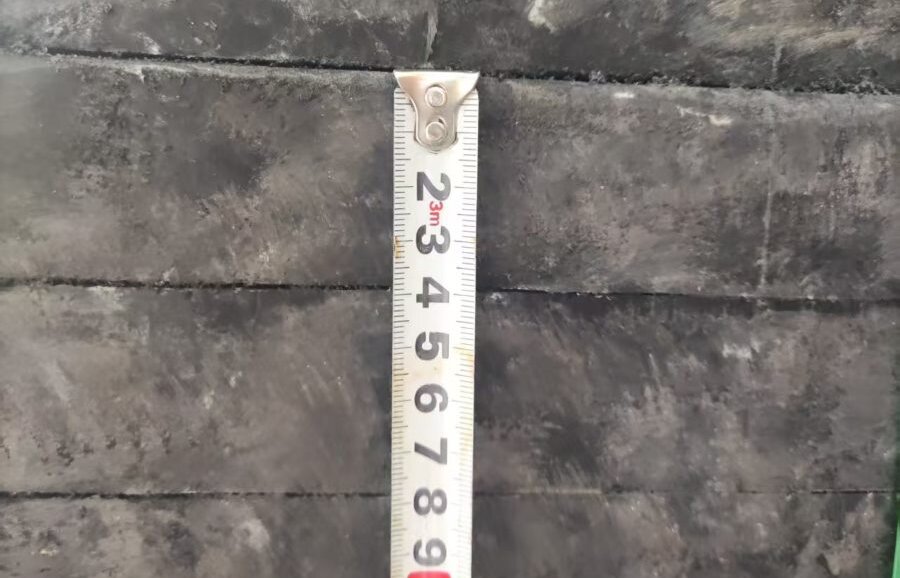

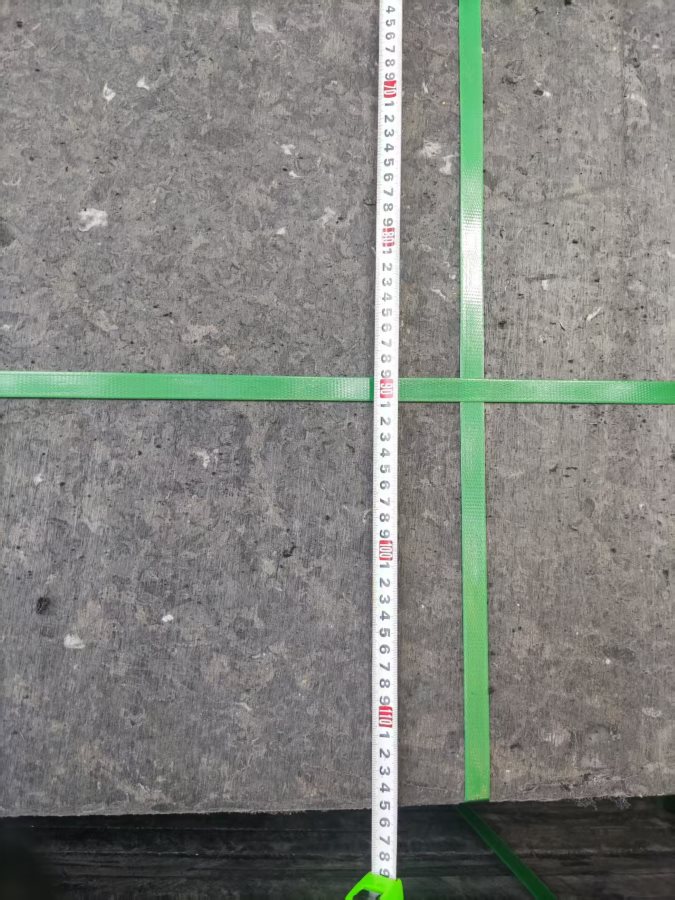

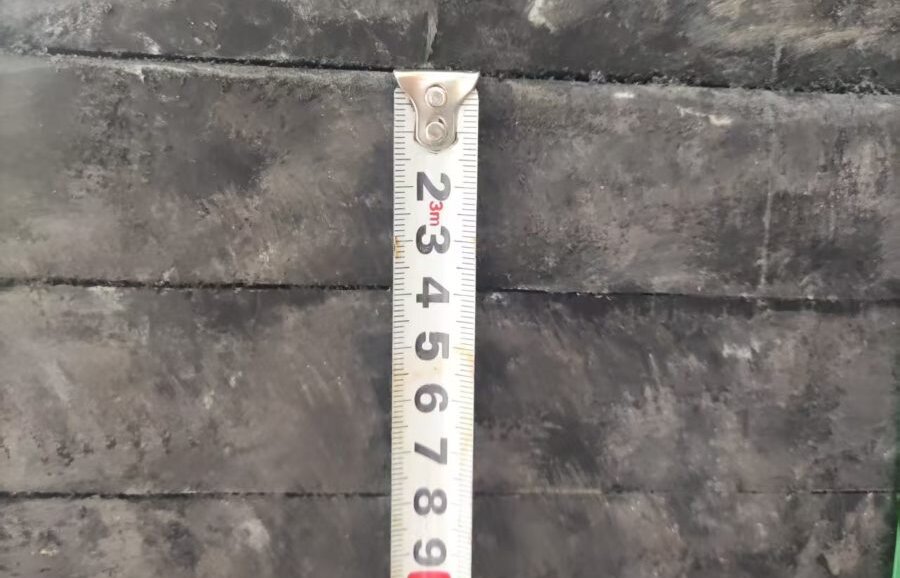

After the initial consultation and understanding the specific needs of the client, Hawen Machinery customized the 1150x950x40mm GMT pallets to perfectly match their automatic block machines. The pallets were packed securely and shipped from our warehouse, ensuring safe and timely delivery to Congo.

*Why Choose GMT Pallets for Block Production?

1.Durability and Longevity:

GMT pallets are made using high-strength thermoplastic materials reinforced with glass fibers, making them exceptionally durable and able to withstand the high pressures involved in block production. The design and material composition allow them to have an extended service life, making them a highly cost-effective option for businesses that require long-term solutions for block production.

2.Enhanced Stability in Production:

The rigidity of GMT pallets ensures that the molding of concrete blocks remains precise and stable during the compaction process. With consistent and uniform strength distribution, the pallets prevent warping or bending, which could otherwise affect the quality of the produced blocks.

3.Lightweight but Strong:

Despite their robust construction, GMT pallets are lightweight compared to traditional wooden pallets. This makes them easier to handle and manage in high-output environments while maintaining maximum load-bearing capacity. This balance between weight and strength is ideal for large-scale block production facilities.

4.Resistance to Environmental Factors:

Unlike wooden pallets, GMT pallets are immune to moisture, mold, and decay. Their resistance to weather conditions such as humidity, temperature fluctuations, and exposure to wet environments ensures that they maintain high performance even in challenging production settings.

5.Maintenance-Free and Eco-Friendly:

GMT pallets require very little maintenance, reducing downtime and ensuring smooth operations. Moreover, these pallets are a sustainable alternative to traditional wood, which contributes to environmental conservation, making them a more eco-friendly option in the long run.

*Hawen Machinery in the Congo:

Hawen Machinery is excited to be a key player in the growing building material market in Congo, where the demand for quality precast concrete products is increasing rapidly. With urbanization and infrastructure development booming in the region, the need for efficient, high-quality production equipment has never been greater.

Hawen Machinery has been at the forefront of providing solutions for block production in Congo, where our block making machines, including the QT series block making machine, paver making machines, and GMT pallets, have been well-received by local businesses. Our advanced technology is making it easier for manufacturers in Congo to meet the growing demand for concrete products while maintaining high production standards and efficiency.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China