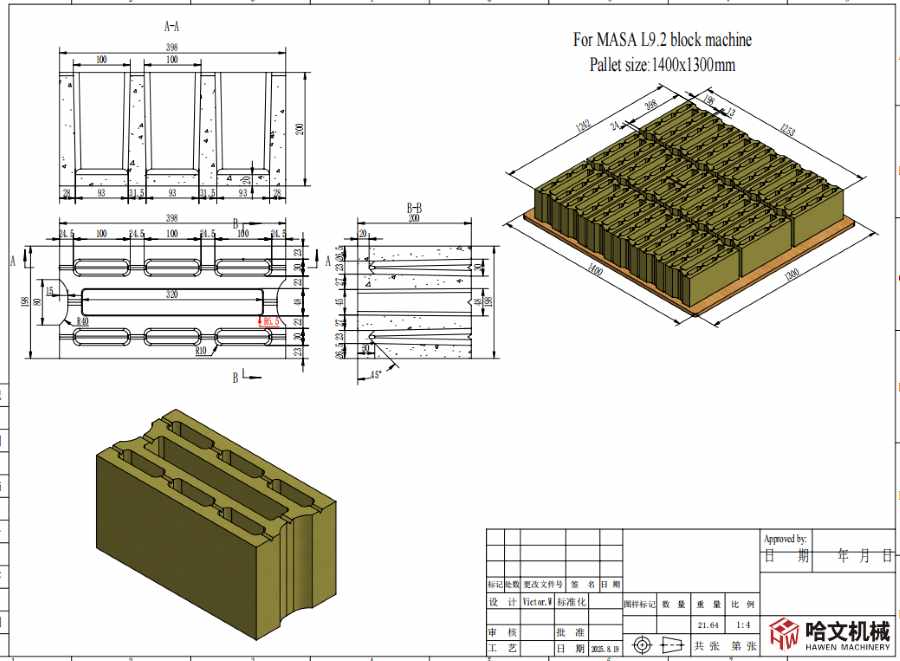

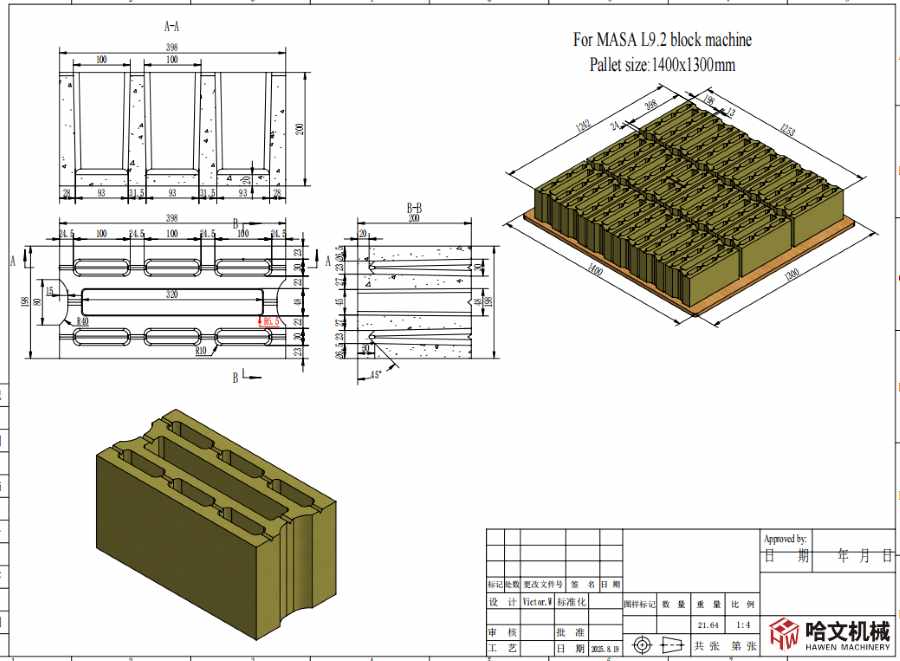

Concrete Block Mould for MASA Machine Shipped to Client in Saudi Arabia

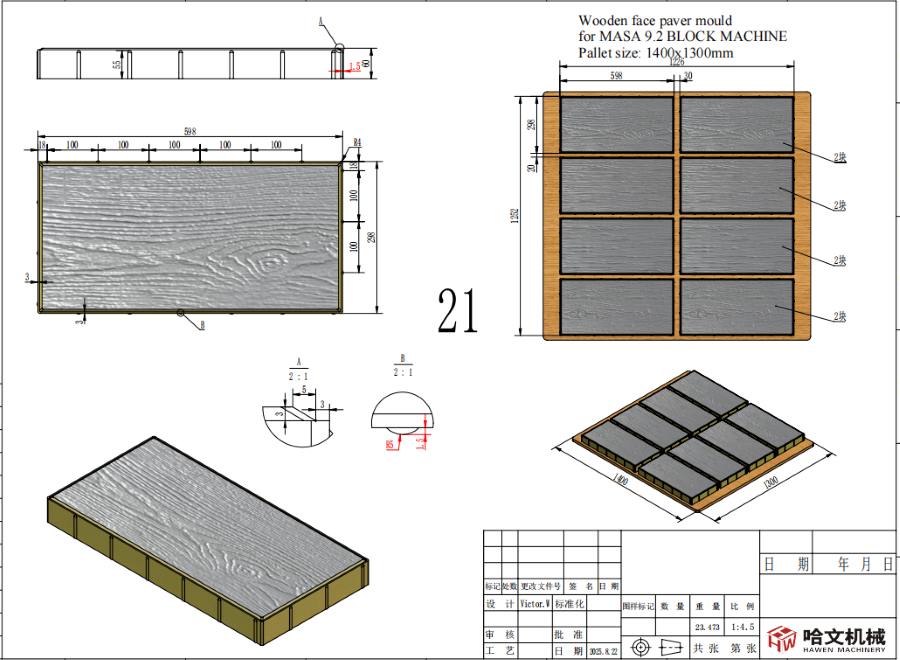

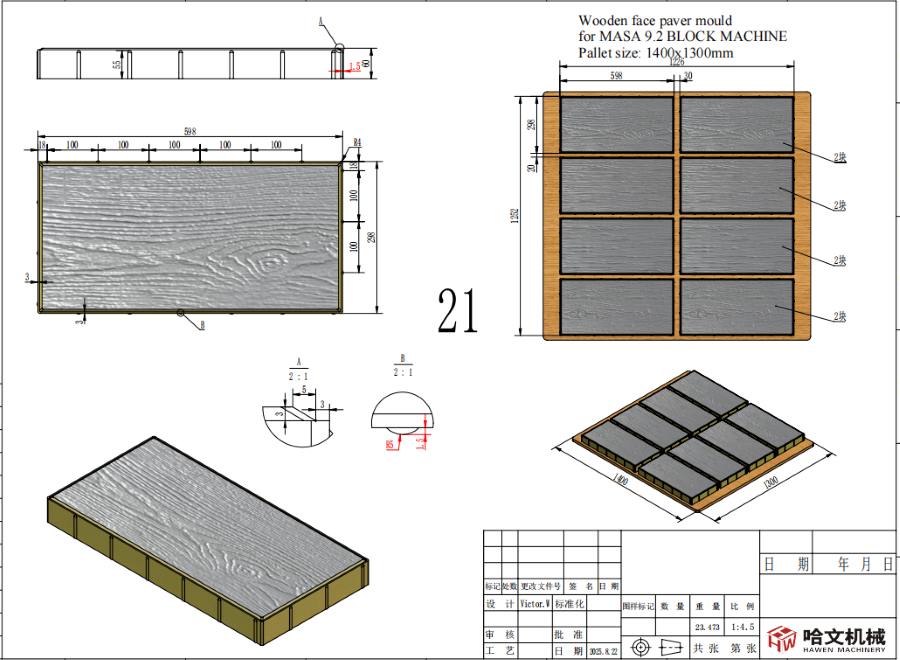

Hawen Machinery is proud to announce the successful completion and shipment of a customized concrete block mould designed for a MASA L9.2 block making machine, with the pallet size at 1400x1300mm to our client in Saudi Arabia. This project reflects Hawen’s ongoing commitment to providing high-quality, precision-engineered moulds that help clients enhance production performance and product consistency.

Background: Meeting the Needs of the Middle Eastern Market

The client, a professional concrete product manufacturer in Saudi Arabia, operates s MASA L9.2 Fully automatic block production lines to meet the growing construction demand in the region. In order to improve block surface finish and ensure longer mould lifespan, the client chose to cooperate with Hawen Machinery for a new set of premium-quality concrete block moulds.

Before placing the order, the client visited our factory to inspect the production facilities, examine the mould manufacturing process, and discuss technical specifications directly with our engineers. This visit allowed the client to gain confidence in Hawen’s capabilities and the quality standards we uphold, ensuring a tailored solution that precisely meets their production needs.

After detailed discussions and design verification, Hawen’s engineering team customized a MASA-compatible block mould that meets both dimensional precision and wear-resistance requirements under high-frequency vibration and long-term operation.

Design & Engineering Excellence

The mould was manufactured in Hawen’s precision machining workshop, equipped with CNC processing centers, digital measuring systems, and advanced heat treatment facilities. Each cavity was processed with accuracy to ensure consistent block size, smooth demoulding, and stable production performance.

To guarantee durability, the mould components were made from high-strength alloy steel and treated with nitriding and hardening processes, achieving a perfect balance between hardness and toughness. After heat treatment, each mould undergoes precise hardness testing, ensuring a hardness of HRC60-62. This guarantees optimal wear resistance and long-term stability during continuous production.The mould’s core box and tamper shoes were precisely aligned to reduce vibration wear and extend service life, even under continuous production conditions.

Although this set of moulds was developed specifically for a MASA block machine, Hawen Concrete Block Moulds are widely compatible with multiple leading international brands, including MASA, HESS, POYATOS, BESSER, and TIGER block machines. Our experienced design team can adapt mould structures, bolt positions, and cavity layouts according to each client’s machine model and production requirements — ensuring perfect fitting and stable performance across different systems.

Inspection, Testing & Quality Control

Before shipment, the mould underwent strict dimensional inspection, assembly testing, and simulated production trials to verify precision and consistency. The surface roughness and cavity accuracy were measured to ensure every detail met international standards.

In addition, Hawen engineers tested the mould’s vibration performance using a simulated vibration table, verifying smooth demoulding, even compaction, and stable block height across the mould area. This thorough inspection process ensures that each mould shipped from Hawen delivers the same quality as our highest-grade production models.

Shipment & Customer Benefits

After quality confirmation, the moulds were carefully packed for safe sea transportation to Saudi Arabia. Upon installation, the moulds will be used for high-strength concrete block production, supporting large-scale infrastructure and residential construction projects in the region.

The moulds provided to the client cover various types, including hollow block mould, paving stone mould with wooden face, interlocking paver mould with smooth face, and curb stone mould, all customized according to specific production requirements.

Hollow block mould drawing

Wooden face paver mould drawing

The Saudi customer praised Hawen’s professional communication, detailed technical design, and strict quality control process, expressing satisfaction with both the product quality and delivery time. The successful cooperation lays a solid foundation for future projects.

Why Choose Hawen Concrete Moulds

With years of experience in mould manufacturing for the block industry, Hawen Machinery provides customized moulds compatible with MASA, HESS, POYATOS, BESSER, and TIGER block machines. We combine advanced CNC machining, precision assembly, and optimized heat treatment technology to deliver moulds that guarantee:

High dimensional accuracy and block consistency

Extended mould lifespan under continuous operation

Smooth demoulding and fine concrete surface texture

Compatibility with major international block machine brands

This successful delivery to Saudi Arabia demonstrates Hawen’s technical strength, international cooperation capability, and dedication to client satisfaction. We continue to provide our global customers with high-quality moulds and complete block production solutions that drive efficiency and success in the concrete products industry.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China