Successful Delivery of Custom Concrete Block Mould for Quadra Q10 Block Machine to Morocco Client

In the competitive world of concrete block manufacturing, finding the right mould that perfectly integrates with your equipment can make all the difference. We're thrilled to share a recent success story from our portfolio: the seamless delivery and implementation of a high-quality concrete block mould tailored for a Quadra Q10 block machine to one of our valued clients in Morocco. This case highlights our commitment to providing durable, precision-engineered moulds that enhance production efficiency and product quality for concrete block producers worldwide.

Understanding the Client's Needs: A Quadra Q10-Compatible Solution

Our client, a prominent concrete block manufacturer based in Morocco, operates a Quadra Q10 block machine – a robust and high-performance system known for its versatility in producing a wide range of concrete blocks, pavers, and curbs. As their production demands grew, they sought a reliable supplier for a custom concrete block mould that could withstand heavy-duty use while maintaining precise dimensions and smooth finishes.

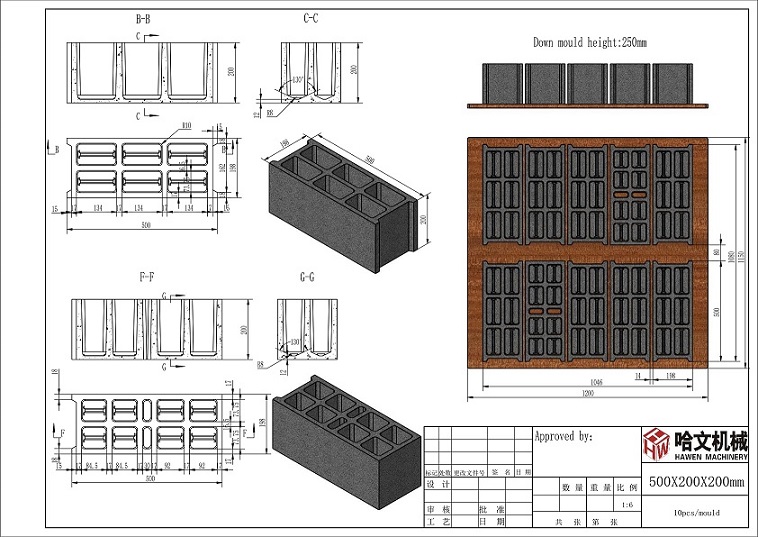

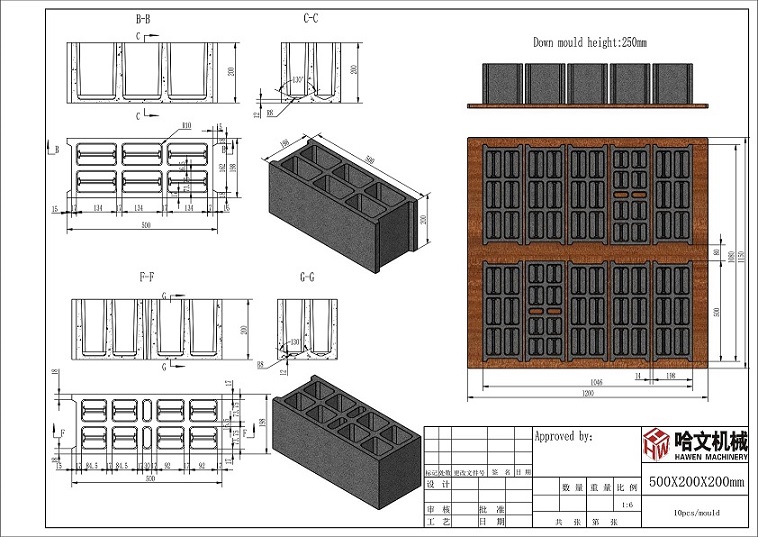

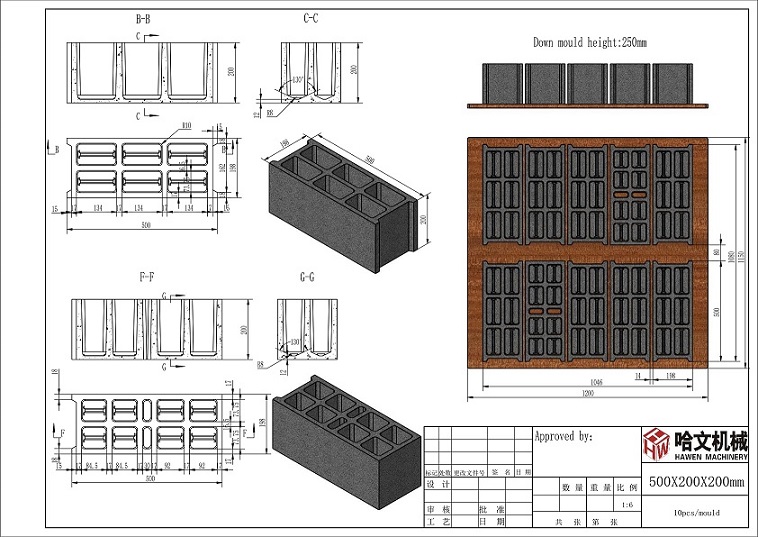

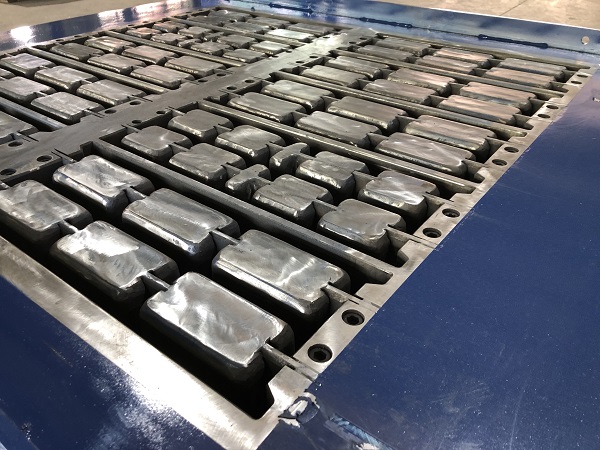

After thorough consultations, we designed and manufactured a mould specifically optimized for the Quadra Q10. Key features included:

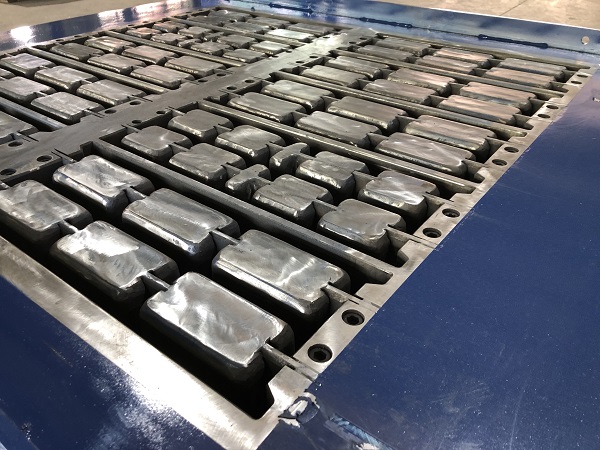

- High-Grade Steel Construction: Built from premium abrasion-resistant steel to ensure longevity and minimal wear, even under high-volume production cycles.

- Customizable Cavity Design: Tailored to produce standard hollow blocks, solid blocks, and interlocking pavers, allowing our client to diversify their product line without additional equipment investments.

- Precision Engineering: Engineered to exact Quadra Q10 specifications for seamless integration, reducing downtime and improving output consistency.

- Enhanced Durability Features: Incorporated anti-corrosion coatings and reinforced edges to handle the harsh environmental conditions common in Moroccan construction sites.

This mould not only met but exceeded the client's expectations, enabling them to boost their daily production by up to 20% while maintaining superior block quality.

The Journey: From Design to Delivery

Our process began with a detailed needs assessment via virtual meetings, where we discussed the client's specific requirements for block sizes, shapes, and production goals. Leveraging our expertise in concrete block mould manufacturing, our engineering team used advanced CAD software to create prototypes and simulate performance on the Quadra Q10 platform.

Once approved, production commenced in our state-of-the-art facility, adhering to international quality standards like ISO 9001. The mould underwent rigorous testing, including load simulations and dimensional accuracy checks, to guarantee flawless operation.

Shipping to Morocco was handled efficiently through our global logistics partners, ensuring timely delivery despite international customs procedures. Upon arrival, our technical support team provided remote guidance for installation, helping the client integrate the mould into their Quadra Q10 setup with zero disruptions.

Benefits Realized: Efficiency and Quality in Concrete Block Production

The results speak for themselves. Our Morocco client reported immediate improvements in their operations:

- Increased Productivity: Faster cycle times and reduced maintenance needs translated to higher throughput.

- Superior Block Quality: Consistent mould performance led to blocks with better compressive strength and aesthetic appeal, meeting local building standards effortlessly.

- Cost Savings: By extending the mould's lifespan and minimizing waste, the client achieved significant reductions in operational costs.

- Market Expansion: With the ability to produce a broader range of products, they expanded their offerings to include eco-friendly interlocking blocks, tapping into Morocco's growing sustainable construction sector.

This project underscores why we're a trusted partner for concrete block mould solutions, especially for Quadra Q10 users seeking reliable, custom-fit options.

Why Choose Us for Your Concrete Block Mould Needs?

At Quanzhou Hawen Machinery, we specialize in manufacturing moulds for leading block machines like the Quadra Q10, serving clients across Africa, Europe, and beyond. Our focus on innovation, quality, and customer satisfaction ensures that every mould we deliver drives real business value.

If you're operating a Quadra Q10 block machine in Morocco or elsewhere and need a custom concrete block mould, contact us today for a free consultation. Let's build success together!

Keywords: concrete block mould, Quadra Q10 mould, block machine Morocco, custom concrete moulds, Quadra Q10 compatible mould, concrete block production

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China