HAWEN Concrete Hollow Block Moulds shipped to client in U.A.E

By the middle of July 2025,HAWEN Machinery successfully delivered three sets of high-precision concrete hollow block moulds to a UAE-based customer for use on their Globmac block making machine.

What makes this case remarkable is the level of trust the customer showed—after visiting our factory, inspecting our production process, and confirming our technical capabilities, they signed the contract on-site and made immediate cash payment. This reflects the strong reputation of HAWEN Concrete Moulds in the global concrete block and brick making industry.

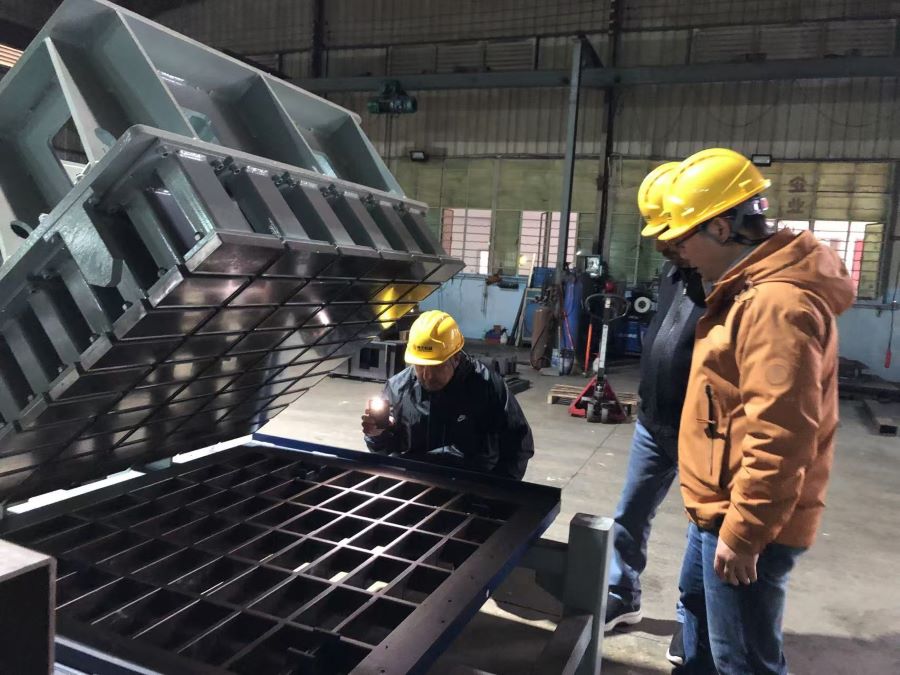

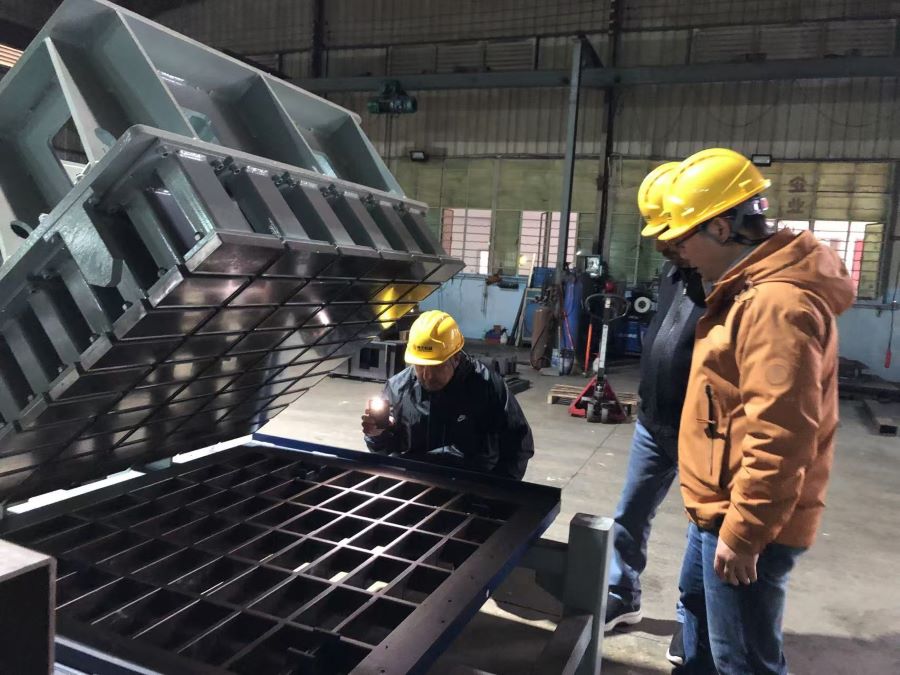

1. Customer Visit & Factory Inspection

This project started with an inquiry from a UAE-based concrete products manufacturer who was looking for a high-strength hollow block mould compatible with a Globmac block making machine. The company had strict requirements: high precision, long service life, and reliable performance under continuous operation for concrete block production.

To ensure they partnered with the right supplier, the customer visited HAWEN Machinery’s manufacturing facility for an on-site inspection. During the visit, they were able to:

Observe our CNC machining workshops, where precision mould components for brick and block making machines are processed.

Inspect moulds for different international brands, including Globmac, MASA, HESS, POYATOS, BESSER, and TIGER, confirming our moulds are designed to fit multiple machine types.

Discuss in detail block specifications, expected output, wear resistance of steel, and heat treatment processes.

The customer was particularly impressed with our track record of supplying customized Concrete Moulds to Middle Eastern and other overseas markets. They emphasized the need for consistent block dimensions and a smooth surface finish—qualities HAWEN Concrete Moulds are well known for.

The trust built during this visit led to an immediate decision—the customer signed the contract and paid in cash before leaving the factory, expediting the production process.

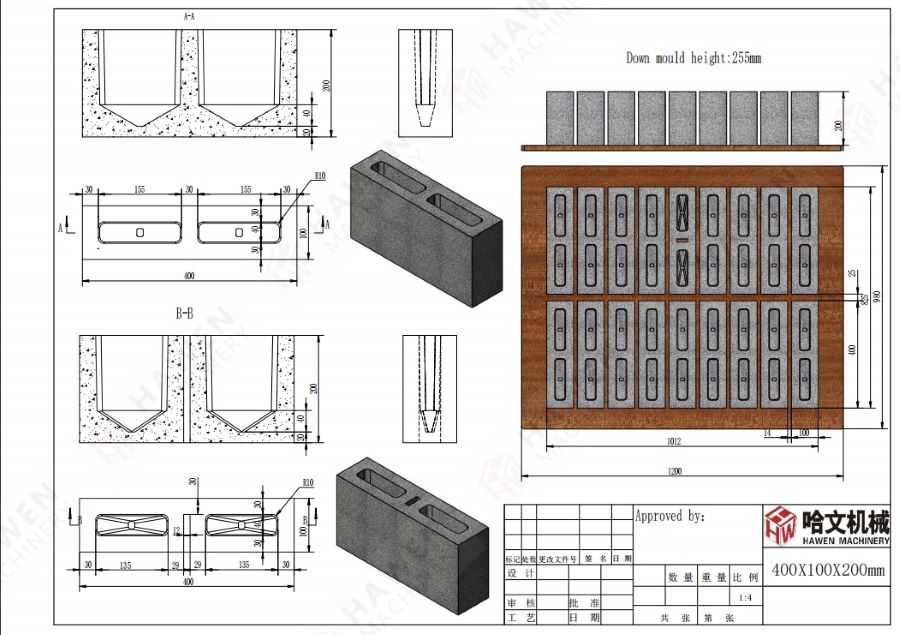

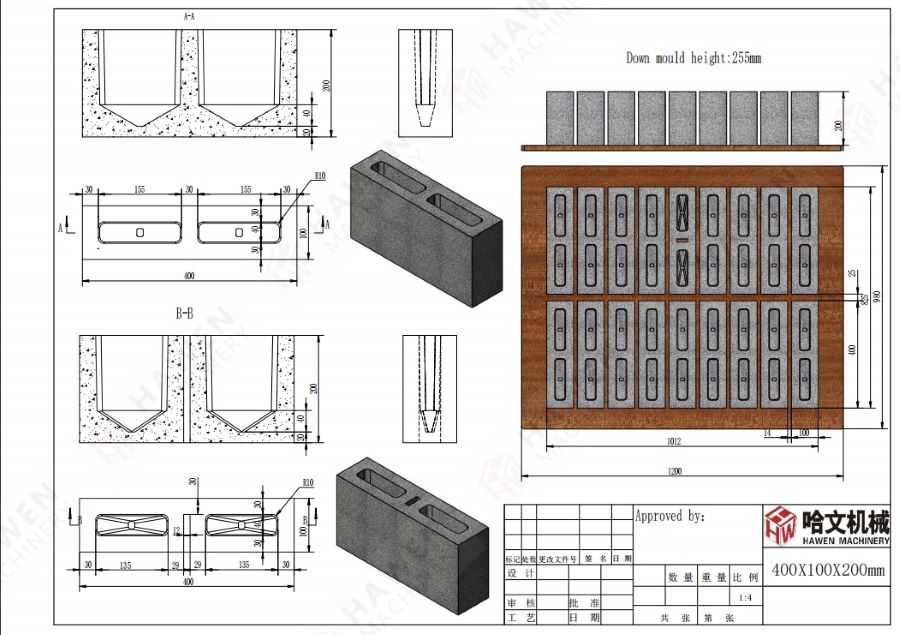

2. Contract Confirmation & Customized Design

After confirming the order, HAWEN’s engineering team immediately started working on detailed technical drawings, tailored precisely to the Globmac machine’s mechanical requirements.

Our design focused on:

Cavity Geometry Optimization – Ensuring stable vibration compaction and uniform block density.

Structural Reinforcement – Strengthening critical parts of the mould frame to resist high-frequency vibration during heavy-duty production.

Easy Demoulding Design – Improving production efficiency by reducing cycle time.

The customer carefully reviewed and approved the drawings, appreciating the fact that we took their specific production needs into account rather than offering a standard, one-size-fits-all solution.

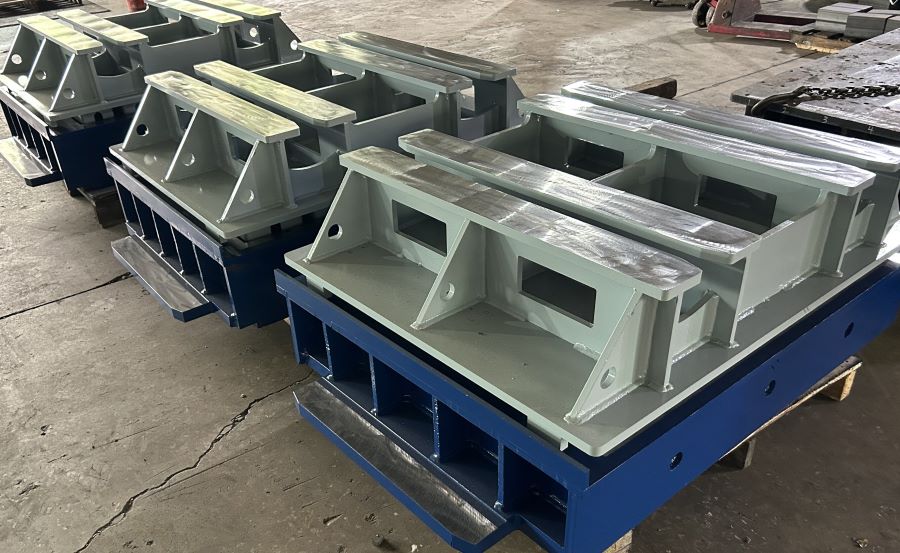

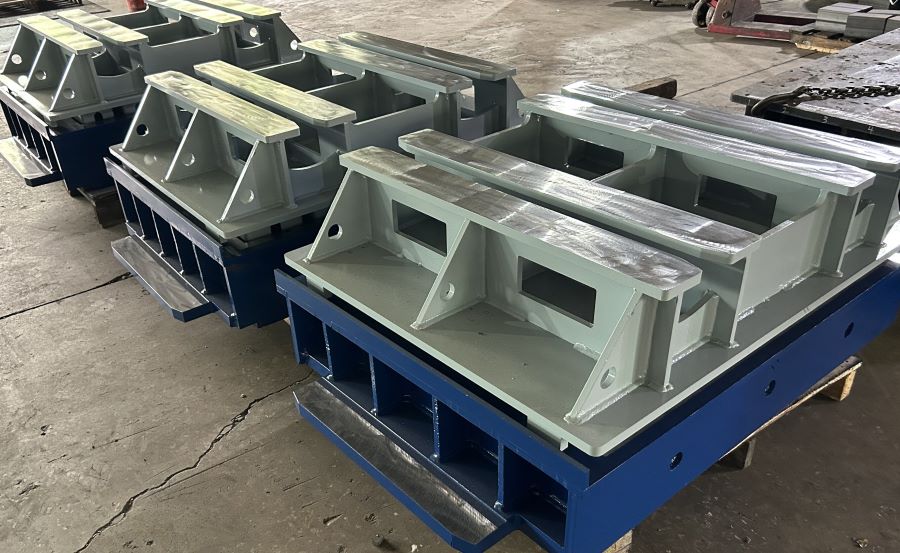

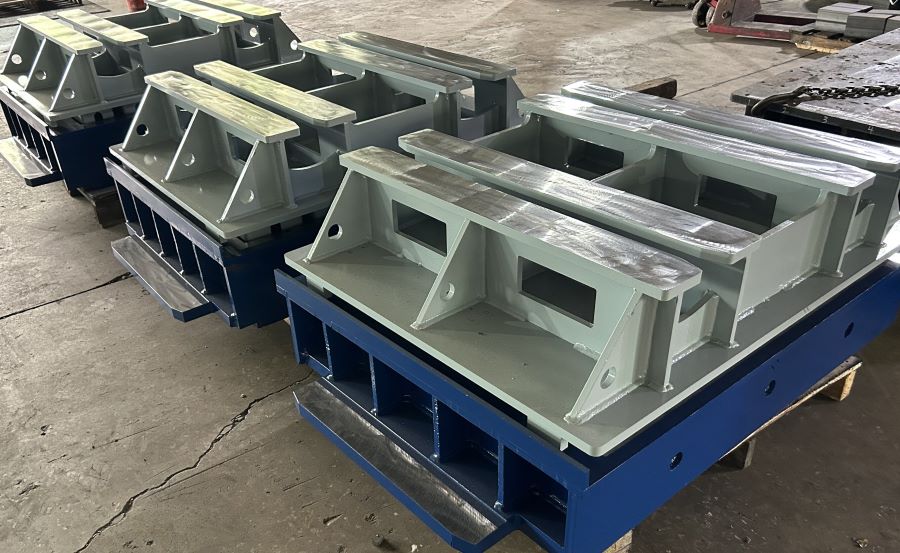

3. High-Precision Production & Process Updates

The production process for this hollow block mould involved:

Premium Alloy Steel Selection – Ensuring high wear resistance and extended service life.

Advanced CNC Machining – Computer-controlled precision machining guarantees tight tolerances, smooth cavity surfaces, and consistent block dimensions.

Heat Treatment & Hardness Testing – Achieving the optimal balance of strength and toughness for long-term durability.

To build customer confidence, we provided regular progress updates with photos at every key stage—steel cutting, CNC cavity shaping, heat treatment, and final assembly. This transparent communication is a standard service for all HAWEN Concrete Moulds orders.

4. Finished Mould Quality Inspection

After production, each mould underwent a strict quality inspection to ensure:

Sharp cavity edges for precise block shaping

Smooth polished surfaces for easy demoulding

Solid frame construction to ensure stable performance on Globmac block making machines

The final photos shared with the customer clearly showed the high-quality finishing, which exceeded their expectations.

5. Safe Packing & Delivery to UAE

The moulds were treated with anti-rust coating and securely packed in reinforced wooden crates to prevent any damage during long-distance transportation.

We arranged land-sea combined logistics, ensuring the moulds were delivered directly to the customer’s production site in the UAE on time and in perfect condition.

6. Why More Customers Choose HAWEN Concrete Moulds?

✔ Versatile Compatibility – Custom-designed for different brands of block making machines, including Globmac, MASA, HESS, POYATOS, BESSER, and TIGER.

✔ Durability & Long Service Life – Premium alloy steel with professional heat treatment withstands continuous production cycles.

✔ Precision & Consistency – Advanced CNC machining ensures accurate block sizes, smooth surfaces, and minimal rejects.

✔ Customization Options – Special block sizes, engraved logos, and unique cavity designs available to meet specific market needs.

✔ Transparent Manufacturing Process – Customers receive real-time production updates for full confidence before delivery.

With years of experience in serving the concrete block and brick making industry, HAWEN Concrete Moulds are trusted by manufacturers worldwide who require stable, efficient, and high-quality block production solutions.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China