Premium Concrete Hollow Block Molds for Poyatos Novabloc Delivered to Thailand

Quanzhou Hawen Machinery Co., Ltd. recently completed a successful delivery of custom hollow block molds for a Poyatos Novabloc machine to a client in Thailand, reinforcing their reputation for delivering top-quality solutions for the construction industry. This article outlines the detailed process of manufacturing durable, high-precision concrete hollow block molds, with placeholders for photos to showcase key production stages.

Overview of Hawen Machinery’s Block Molds

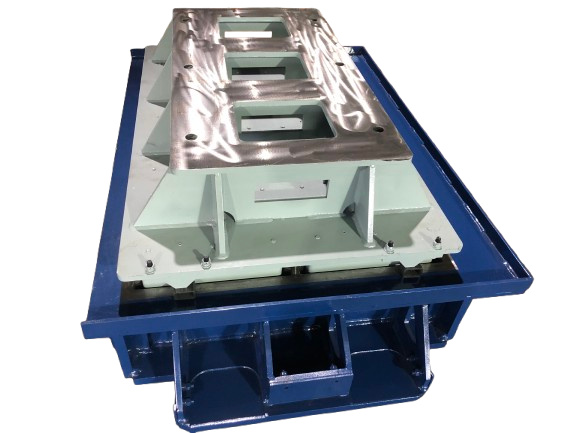

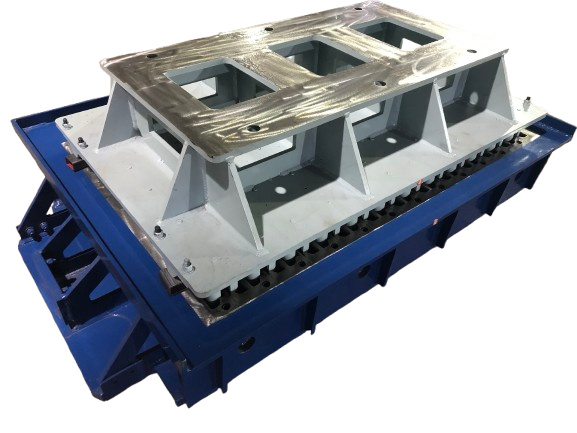

Located in Quanzhou, China, Hawen Machinery excels in producing concrete block molds for global markets. With over a decade of experience, they craft molds for hollow blocks, interlocking pavers, and curb stones, compatible with top-tier machines like Poyatos, MASA, and HESS. Using high-grade materials such as 16# manganese steel and NM500, Hawen’s molds achieve a lifespan of 80,000 to 120,000 cycles, blending durability with precision engineering.

Manufacturing Process for Superior Hollow Block Molds

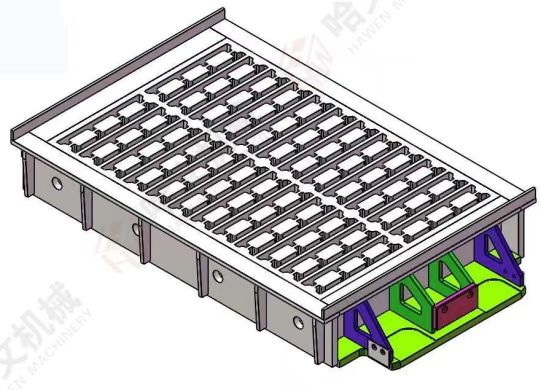

Creating a high-quality hollow block mold demands expertise, advanced technology, and meticulous attention to detail. Below are the key steps Hawen employs to produce molds tailored for machines like the Poyatos Novabloc in Thailand.

1. Tailored Design

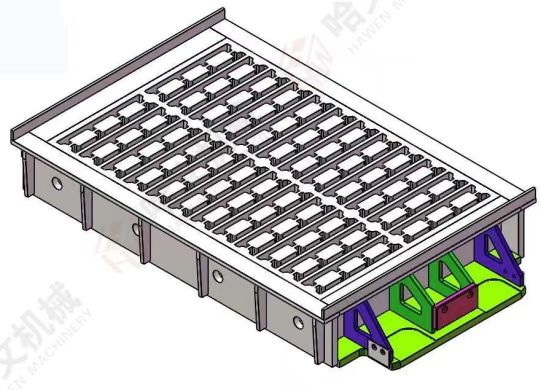

The process starts with a deep dive into the client’s requirements, such as block dimensions (e.g., 390x90x190mm) and compatibility with the Poyatos Novabloc’s 1400x900mm pallet. Hawen’s engineers use CAD software to draft precise mold designs, ensuring perfect block formation and machine integration.

2. High-Grade Material Selection

Hawen selects 16# manganese steel and NM500 for mold frames and tamper heads, valued for their robustness and resistance to wear. These materials ensure the mold endures the rigors of high-volume block production without losing structural integrity.

3. Precision Fabrication

Mold components are shaped using wire-cutting technology for sharp, accurate edges. CNC machining further refines parts to achieve tolerances within ±0.1mm, ensuring blocks have smooth surfaces and precise interlocking capabilities.

4. Strengthening Through Heat Treatment

To enhance durability, molds undergo carburizing, nitriding, and quenching, reaching a hardness of HRC58-62. This treatment ensures resistance to wear and deformation, particularly for high-pressure components like tamper heads.

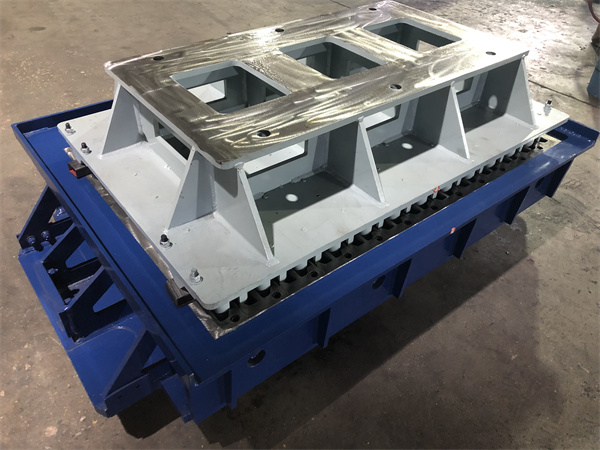

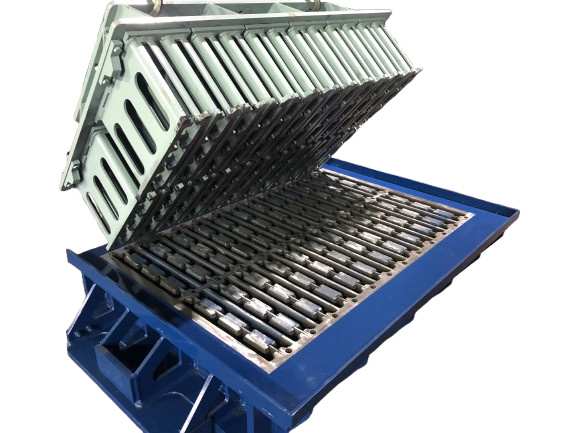

5. Expert Assembly and Quality Checks

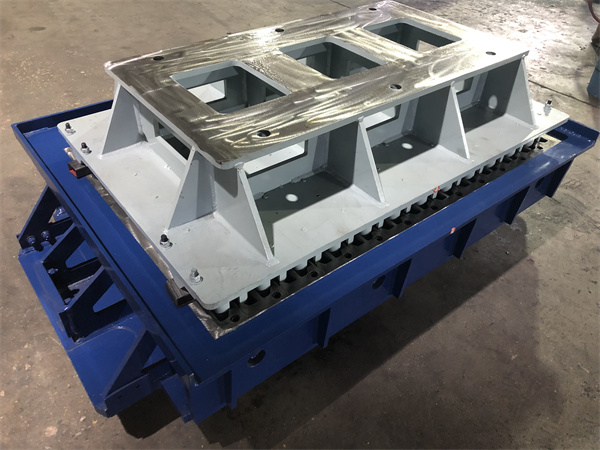

Technicians carefully assemble the mold, followed by comprehensive quality inspections to verify dimensions and compatibility. Hawen tests each mold to ensure it delivers consistent, high-quality blocks with flawless finishes.

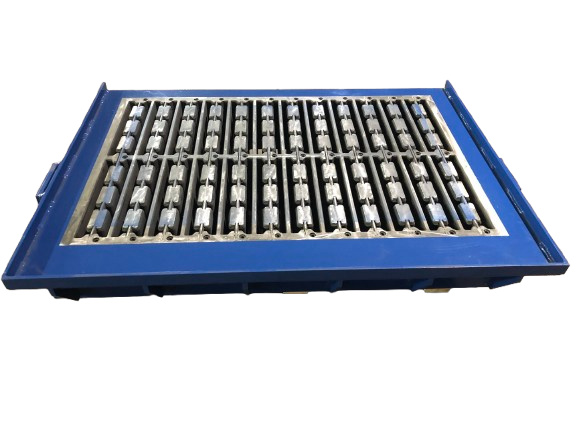

6. Protective Finishing

The mold is polished and coated with anti-corrosion paint, improving both aesthetics and longevity. This final step protects against environmental wear, ensuring a professional, durable product.

7. Secure Packaging and Delivery

Molds are robustly packed for safe international transport. Hawen’s logistics team ensures timely delivery, as demonstrated by the successful shipment to Thailand in June 2025.

Key Benefits of Hawen’s Hollow Block Molds

Hawen’s molds provide distinct advantages for Poyatos Novabloc users:

Precision: Delivers uniform blocks with clean edges for structural integrity.

Longevity: Heat-treated steel supports 80,000–120,000 cycles, reducing costs.

Customization: Tailored to client-specific block and machine requirements.

Efficiency: Streamlines demolding for faster production.

Global Standards: Compatible with leading machines like Poyatos and MASA.

Hawen Machinery’s delivery of custom hollow block molds to Thailand highlights their expertise in producing reliable, high-performance molds for the Poyatos Novabloc. Through premium materials, precise craftsmanship, and rigorous testing, Hawen meets the demands of construction professionals worldwide. Learn more at www.hawenblockmachine.com

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China