Hawen Automatic Cuber System Successfully Shipped to valued client in UAE

In the end of September 2025, Hawen Machinery successfully shipped a complete Automatic Cuber System from Xiamen Port to our valued client in the Al Ain city,UAE. The shipment, expected to arrive by the end of October, highlights another important step in Hawen’s dedication to delivering advanced automation solutions for concrete block production lines worldwide.

This UAE client has been operating a QT15 block making production line supplied by Hawen Machinery. With the rapid increase in production capacity, the factory faced the challenge of high labor demand for manual cubing and stacking. To improve efficiency and reduce manpower costs, the client decided to integrate Hawen’s Automatic Cuber System into their existing production line.

After evaluating multiple options, the client chose Hawen Machinery once again because of our strong technical expertise, reliable service support, and proven reputation in both block making machines and automation solutions. This project marks not only an upgrade in production efficiency but also a strategic step toward factory-wide automation.

Key Features and Advantages of the Automatic Cuber System:

The Automatic Cuber System is a critical component for modern block production lines, replacing intensive manual labor with intelligent automation. Hawen Machinery’s system has been meticulously engineered to ensure precision, efficiency, and reliability. Key features include:

1.Servo-Controlled Walking and Lifting: Guarantees smooth, accurate, and stable block handling.

2.High Efficiency: Rapid and continuous stacking of blocks onto pallets, significantly reducing production time.

3.Labor Cost Reduction: Minimizes the need for manual stacking, lowering workforce expenses and improving safety.

4.Seamless Integration: Fully compatible with the existing QT15 block making line, ensuring smooth workflow.

5.Enhanced Factory Automation: Contributes to a more automated, modern, and scalable production process.

6.Durable and Reliable Design: Built for long-term operation with minimal maintenance, ensuring consistent performance.

This system enables the UAE client to maximize productivity, reduce operational costs, and achieve a higher level of automation in their block production process.

Why UAE Client Chose Hawen Machinery Once Again?

The UAE client had already been operating a QT15 block making production line supplied by Hawen Machinery. As production capacity grew, the client faced rising labor costs and efficiency challenges in the block stacking process.

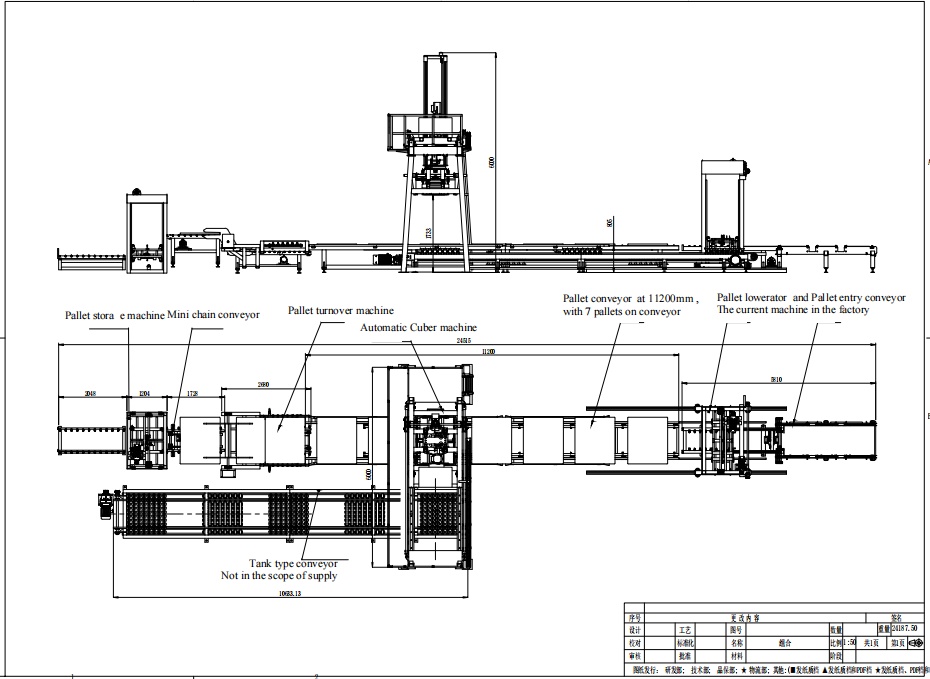

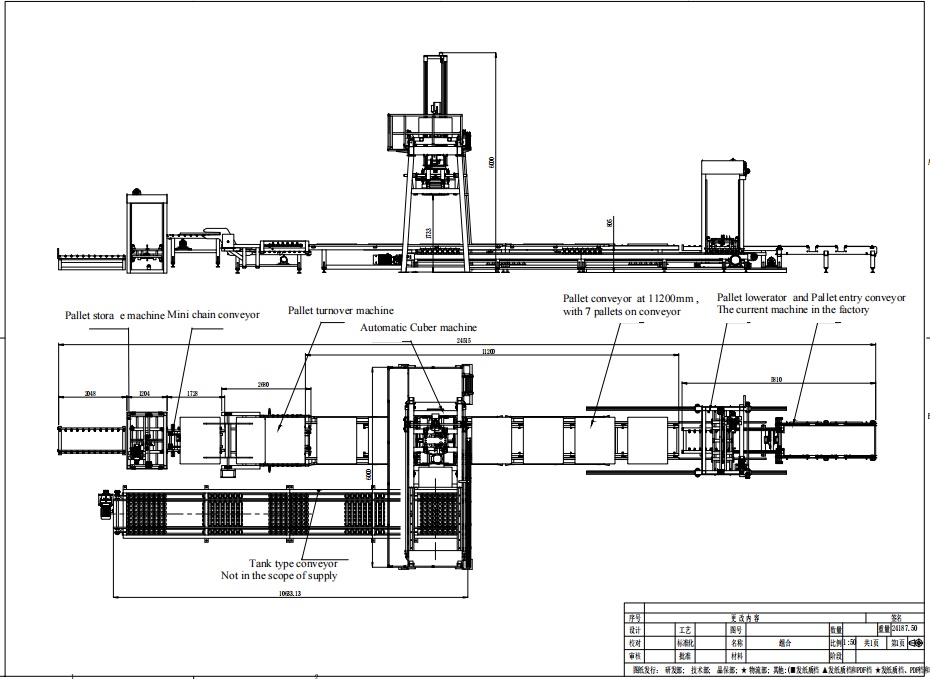

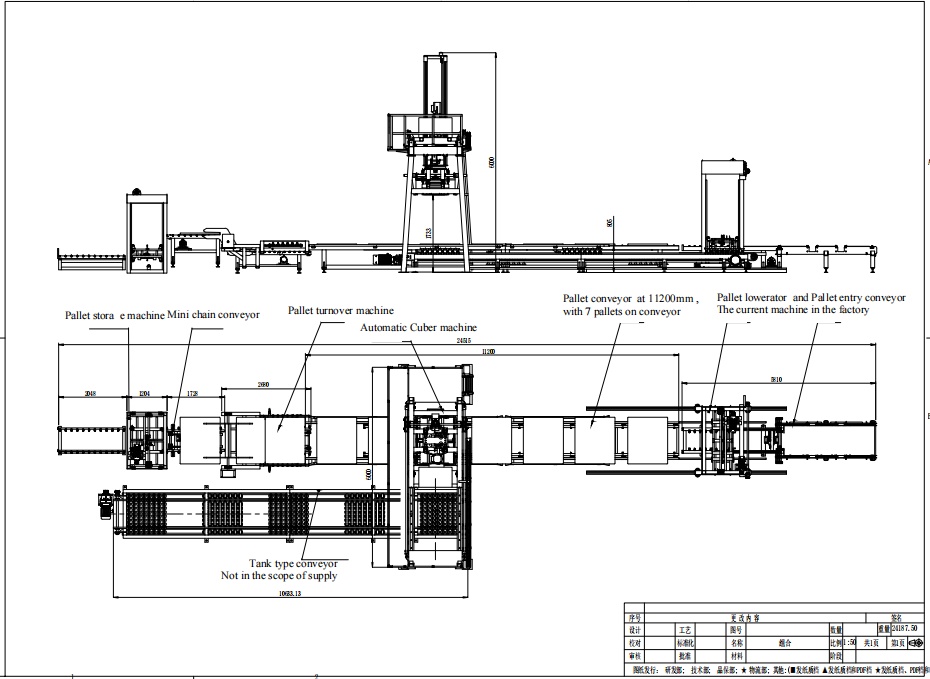

Before placing the order, Hawen’s engineering team provided the client with detailed technical proposals and layout drawings, helping them clearly understand how the Automatic Cuber System would integrate with their existing QT15 block making production line. This professional support gave the client confidence in the feasibility and efficiency of the solution.

After evaluating several international suppliers, the client chose Hawen Machinery because:

1.Higher Automation Level: Our Automatic Cuber System is equipped with servo-controlled lifting and walking, delivering precise, stable, and highly automated stacking compared to traditional systems.

2.Proven Experience: Hawen Machinery has a solid track record of successful projects in the Middle East, providing reliable solutions and service support to block factories in the region.

3.Complete Solution Provider: Beyond block machines (block making machines, brick making machines), Hawen Machinery also supplies concrete moulds and automatic cuber systems, offering clients a one-stop automation solution.

Production, Shipment, and Next Steps:

The cuber system underwent strict quality inspections prior to shipment. Each key component was carefully tested to ensure stable performance and durability under continuous operation.

Upon arrival, Hawen’s technical engineers will assist with installation, testing, and commissioning, ensuring seamless integration with the client’s existing QT15 block production line.

Once operational, the Automatic Cuber System will drastically improve stacking efficiency, reduce labor requirements, and enhance overall factory automation.

Conclusion:

The successful shipment of the Automatic Cuber System to the Al Ain city,UAE underscores Hawen Machinery’s growing global presence and our expertise in delivering servo-controlled, fully automated solutions for the concrete block industry.

By upgrading from manual stacking to intelligent cubing, our UAE client will achieve higher productivity, consistent block stacking, and significant labor cost savings.

This project represents another strong step in Hawen Machinery’s mission to support concrete block factories worldwide with innovative, reliable, and cost-effective automation solutions.

Tel: +86-13905968794

Tel: +86-13905968794 Email: export@hwmachines.com

Email: export@hwmachines.com MP/WhatsApp: +86-13905968794

MP/WhatsApp: +86-13905968794 Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China

Manufacturer Address:Nanan,Quanzhou City,Fujian Province,China